Buckle, air outlet grating of air conditioner, front shell of air conditioner and outdoor unit of air conditioner

A technology for air outlet grilles and front shells, which is applied in the fields of air conditioner front shells, air conditioner outdoor units, clips, and air conditioner air outlet grilles. It can solve the problems of low assembly efficiency, inability to disassemble, and increased heat Melt glue fixation and other problems, to achieve the effect of low assembly labor intensity, high assembly efficiency, and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

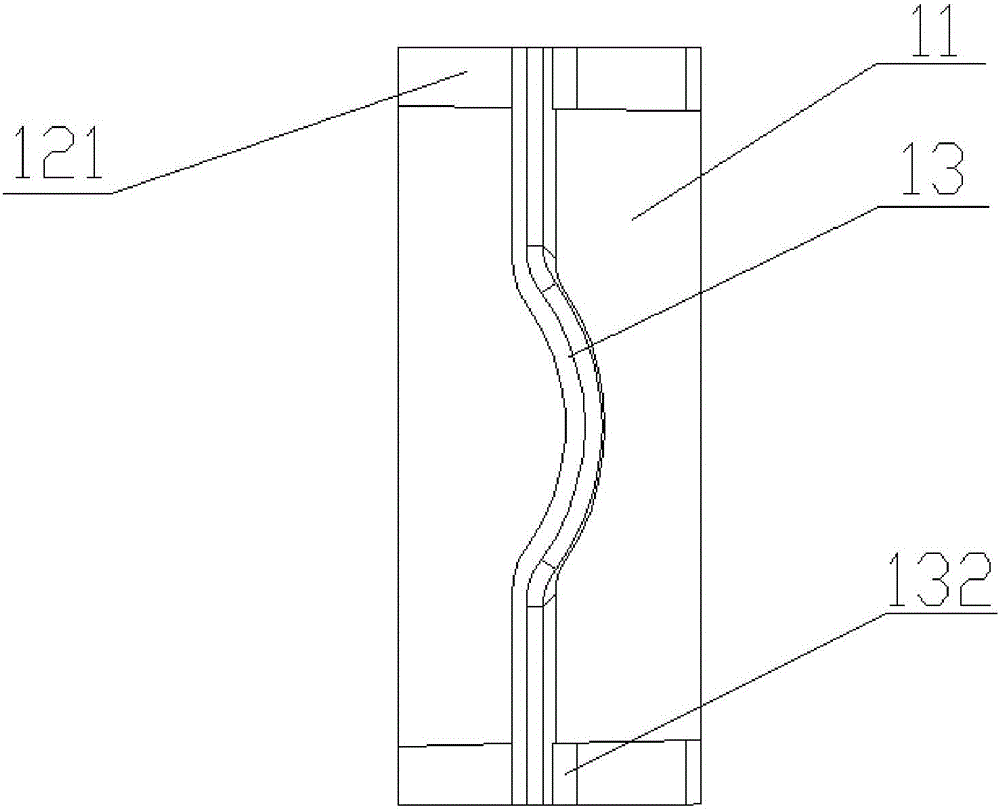

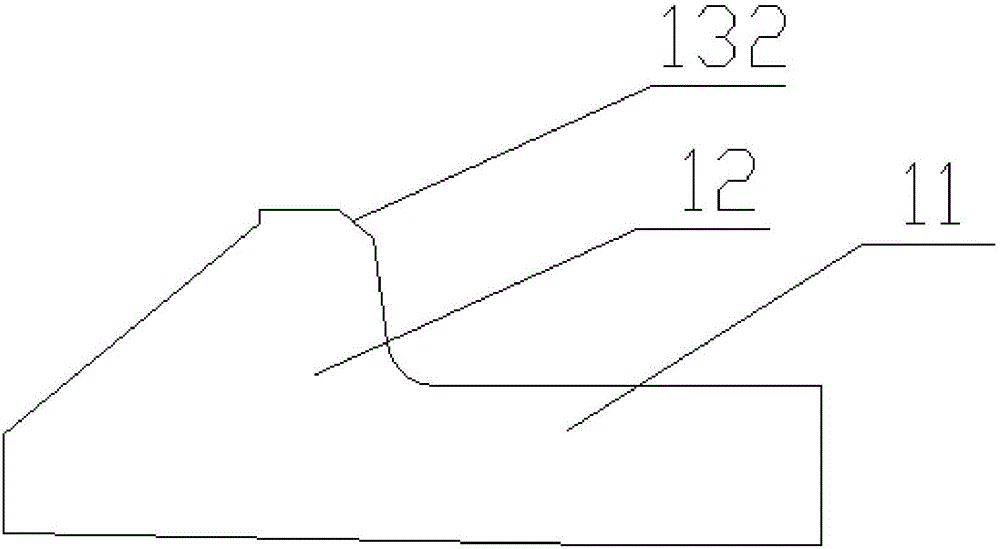

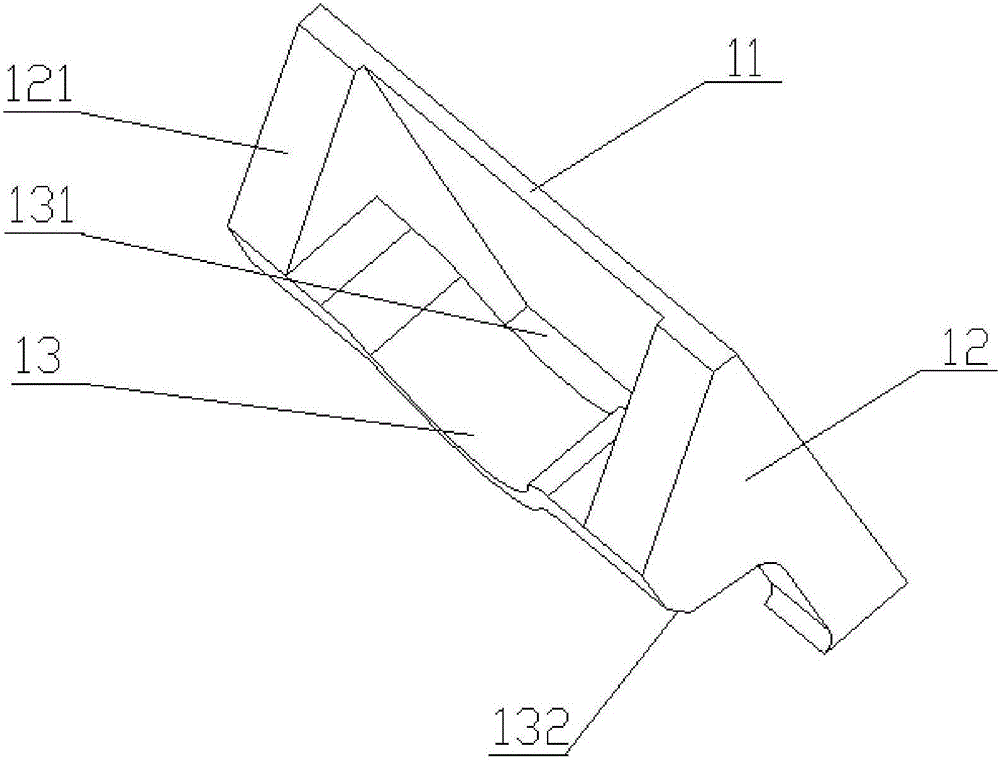

[0040] like figure 1 , figure 2 , image 3 As shown, a buckle 1 includes a base plate 11; ribs 12 extend from the left ends of the upper and lower sides of the base plate 11 to the top respectively; the ribs 12 have a first guide surface 121; the first guide surface 121 is The left side of the bottom of the rib 12 to the top of the rib 12 is inclined towards the right side of the substrate 11; an elastic arch buckle part 13 is fixed between the two ribs 12; Right.

[0041] There is a gap 131 between the elastic arch buckle part 13 provided by the present invention and the base plate 11 . The top surface of the elastic arch buckle part 13 is in the same plane as the top surface of the reinforcing rib 12; the elastic arch buckle part 13 has a second guide surface 132; the second guide surface 132 is the top right side of the elastic arch buckle part 13 The side slopes downward toward the right side of the substrate 11 .

[0042] The included angle between the first guiding...

Embodiment 2

[0046] like Figure 4 , Figure 5 , Image 6 As shown, an air-conditioning outlet grille 2, at least one buckle as in Embodiment 1 is fixed on at least two opposite sides of the grille 2; wherein the direction of the vault of the elastic arch buckle part 13 and the wind direction unanimous.

[0047] Usually the grille 2 is rectangular, and each side thereof is provided with two buckles. In addition, screw holes 21 are provided at two opposite corners of the grille 2 to facilitate secondary fastening with self-tapping screws.

Embodiment 3

[0049] like Figure 7 , Figure 8 As shown, an air conditioner front shell 3, at least one slot 31 is provided on at least opposite sides of the front shell 3; a front shell buckle part 32 is fixed in the slot 31; the front shell buckle part 32 includes a self- The guide plate 321 extending inwardly from the side of the slot 31 close to the edge of the front case 3; the front end of the guide plate 321 has a flange 322 facing the periphery of the front case 3; Part 3221; the vault of the arched positioning portion 3221 faces the front shell 3; the diameter of the arched positioning portion 3221 is greater than the arched outer diameter of the elastic arched buckle part 13.

[0050]Usually, the front shell 3 of the air conditioner is rectangular; two slots 31 are provided on each side thereof; each slot 31 is provided with a front shell buckle part 32 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com