Nondestructive sampling method of cemented filling body

A technology of cemented filling and non-destructive sampling, applied in the direction of sampling devices, etc., can solve the problems of cemented filling body disturbance, damaged structure, sample damage, etc., and achieve the effect of non-destructive and reliable sampling, good quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

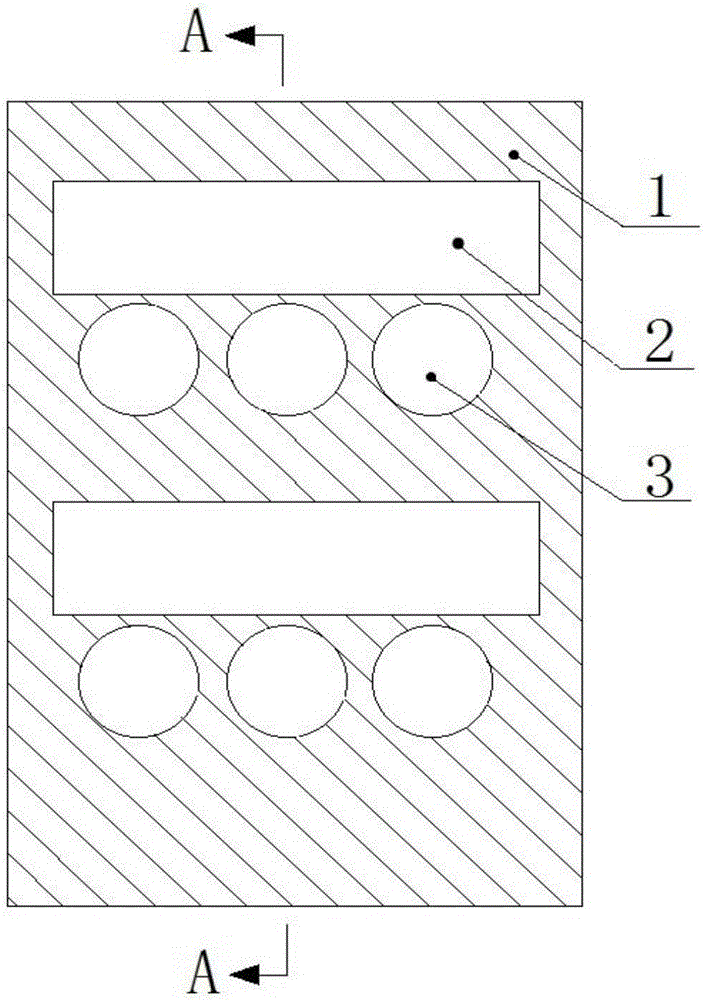

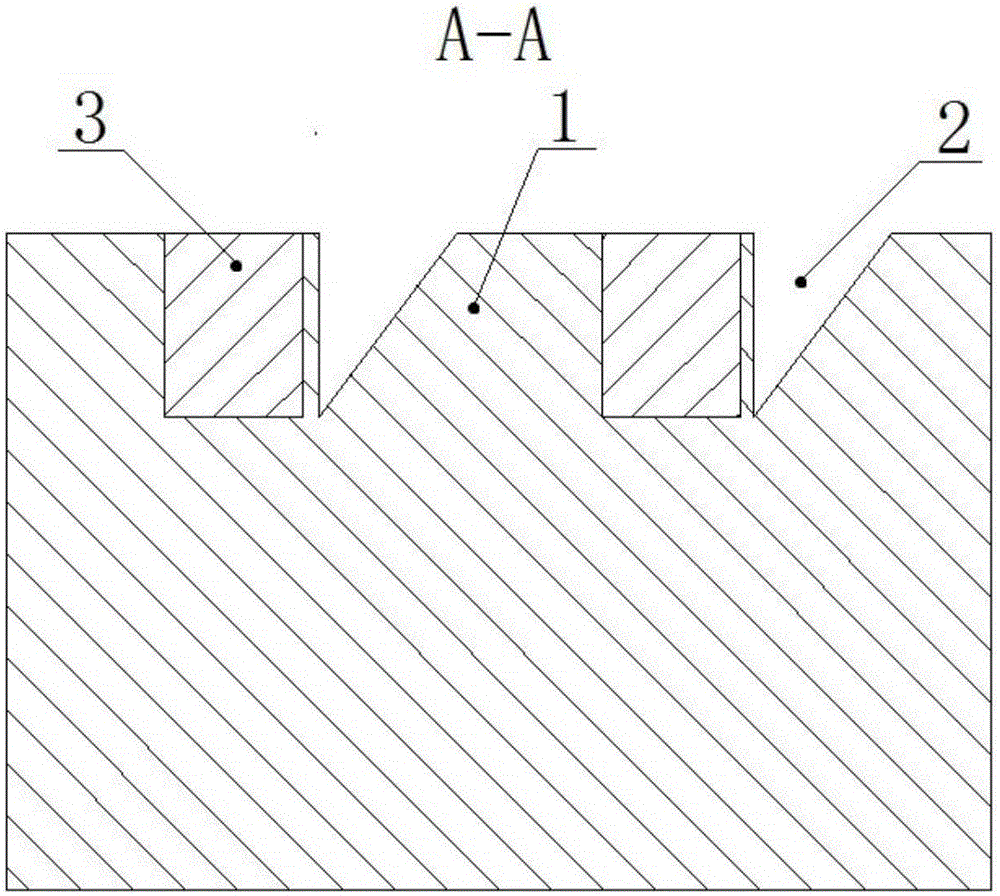

[0023] The invention discloses a non-destructive sampling method for a cemented filling body. In the method, a wedge-shaped groove 2 is first formed on the surface of the cemented filling body 1, and then a cylindrical sample 3 is taken along the length direction of the wedge-shaped groove 2. The specific steps are as follows:

[0024] (1) if figure 1 and figure 2 As shown, on the surface of the cemented filling body 1 that needs to be sampled, select a suitable position, and cut a wedge-shaped groove 2 with a cutting saw. One wedge surface A of the wedge-shaped groove 2 is perpendicular to the surface of the cemented filling body 1, and the other wedge surface B is oblique Next, the notch width of the wedge-shaped groove 2 is 150mm, the groove depth of the wedge-shaped groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com