Four-path gas component measurement pyroelectric infrared detector

A pyroelectric infrared and gas composition technology, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of using stains to affect the optical path, low detection rate, weak signal output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the present invention.

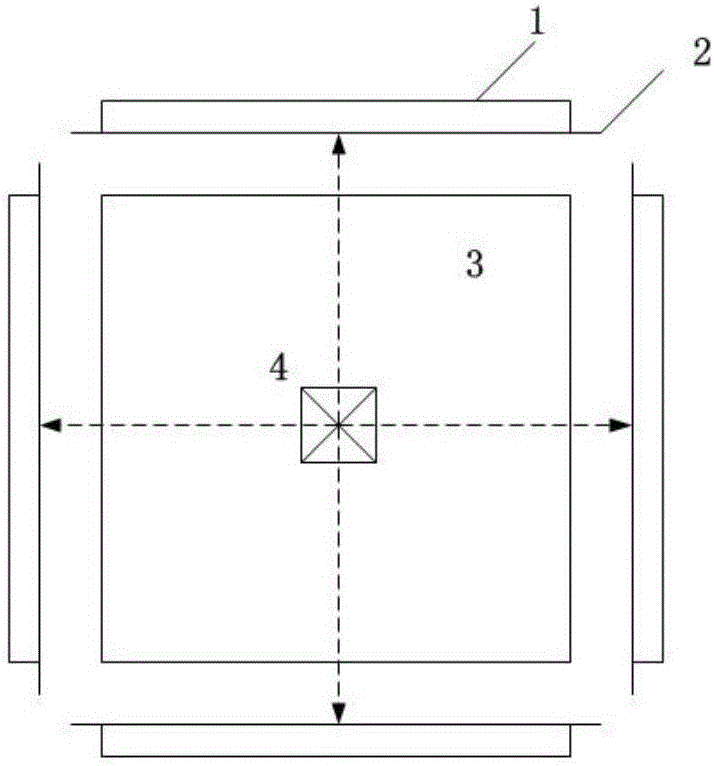

[0020] Such as figure 1 Shown is an embodiment of the present invention: a four-channel pyroelectric infrared detector for measuring gas components includes a detector housing, a spectroscopic array 3 disposed in the housing, capable of receiving a light source, and four detection units, a single detection unit It includes a piece of pyroelectric crystal sheet 1 and a piece of narrow-band infrared filter 2; wherein, a light-through hole is provided on the detector housing, a light-splitting array 3 is located directly below the light-through hole, and the four detection units are inclined inward Set in the four light splitting directions of the light splitting array 3, and the four pyroelectric crystal sheets 1 are respectively per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com