Clamping tool for antenna test and test method

A technology for antennas and fixtures, applied in fixtures for antenna testing and in the field of testing, can solve the problems of wasting qualified products, outflowing unqualified products, and decreasing the stability of antenna test fixtures, so as to avoid testing and judgment errors and improve detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

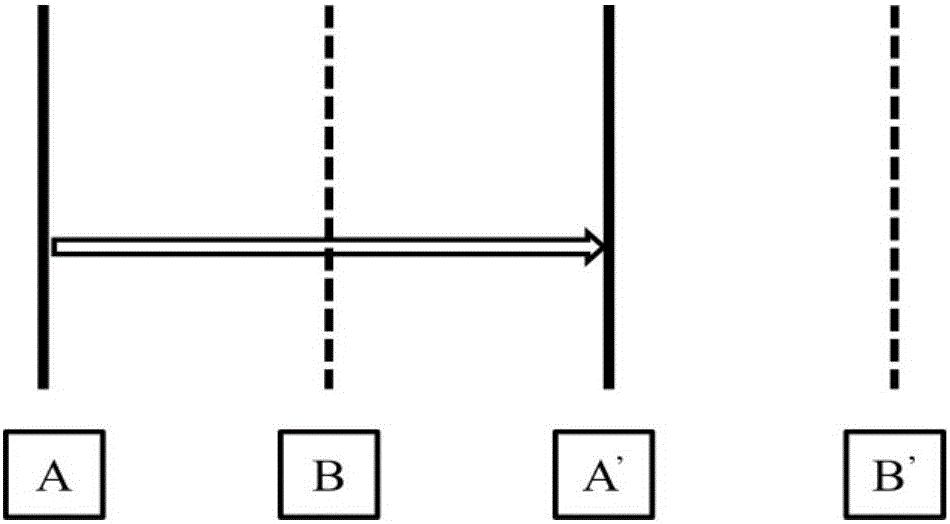

[0024] The most critical idea of the present invention is: the antenna test fixture is provided with at least two electrical performance detection main boards and at least two sets of fixing devices. This design allows the testing of the limit sample and the sample to be tested to be carried out simultaneously, and the test can be performed in the same state. The obtained threshold value is used to determine whether the sample to be tested is qualified or not, which avoids the test and judgment errors caused by the stability fluctuation of the test fixture itself, and improves the detection accuracy.

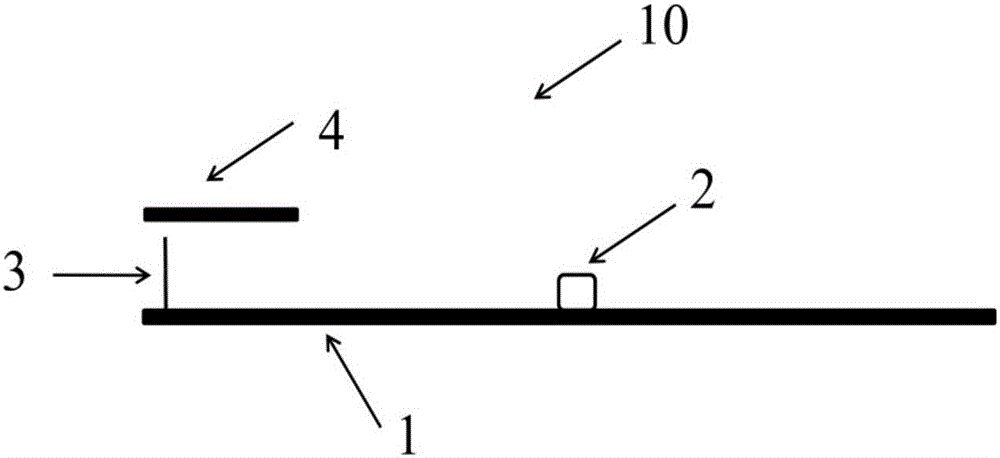

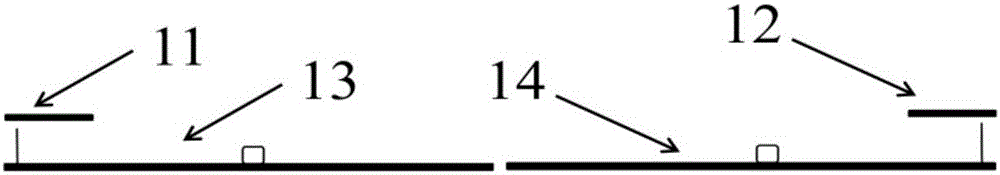

[0025] Please refer to figure 2 and image 3 , a fixture for antenna testing, including a base body, a pressing device, and at least two main boards for elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com