Batched combination machining device for magnetic buckle assembly

A technology of combined processing and components, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as time-consuming and labor-consuming, low production efficiency, low efficiency and safety risks, and achieve simple structure, fast operation speed, The material process is stable and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

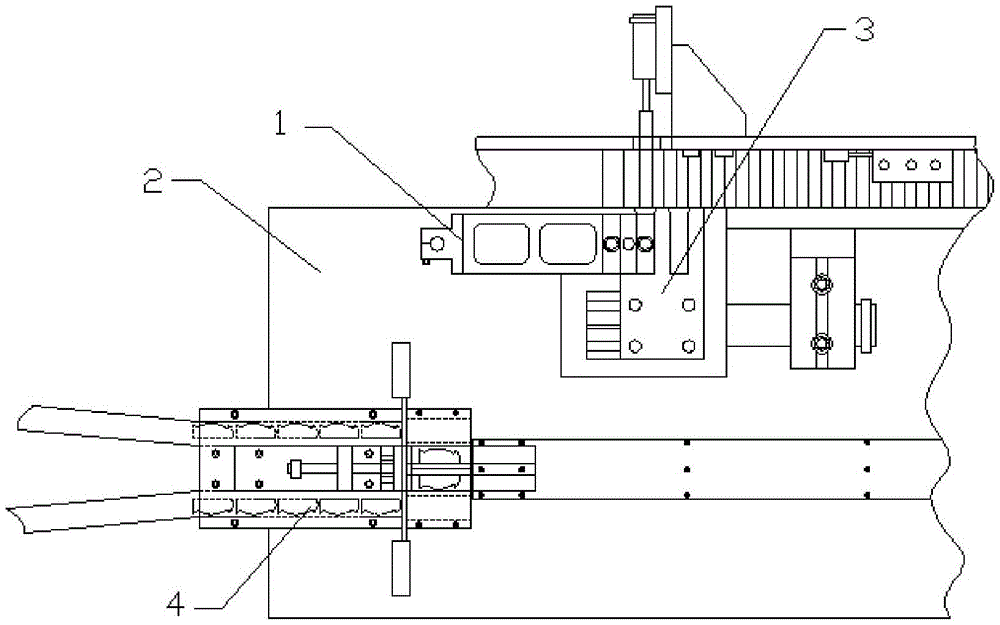

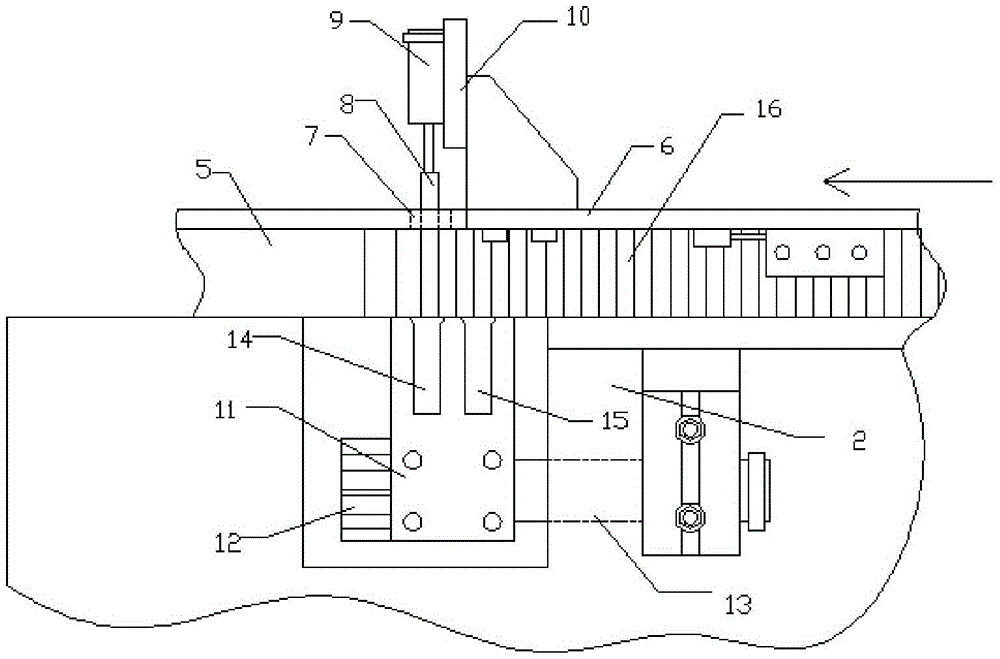

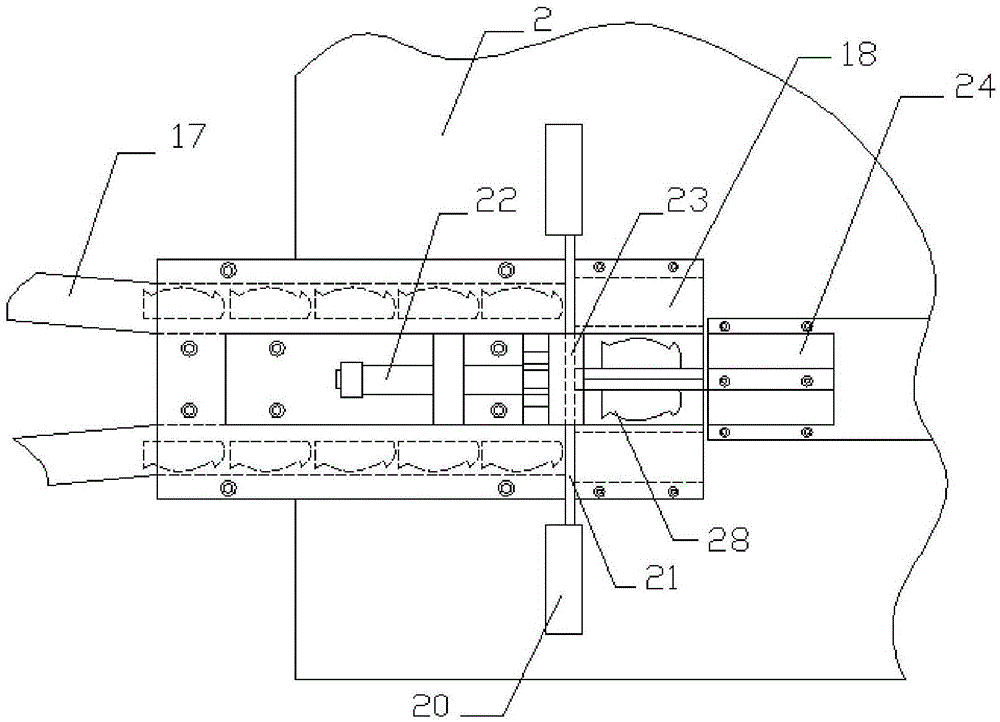

[0021] Refer to attached Figures 1 to 4 , a batch combination processing device for magnetic buckle components, including a mechanical arm 1 and a tooling table 2, it also includes a carrying device 3 and an assembly pushing device 4, wherein the mechanical arm 1 is used to receive the magnets carried in the carrying device 3 block 16, and move the magnet block 16 to the assembly pushing device 4;

[0022] The carrying device 3 is fixed on the tooling table 2 at an angle of 90° with the assembly pushing device 4 .

[0023] The carrying device 3 includes a feeding mechanism, a material pushing mechanism and a feeding mechanism, and the feeding mechanism includes a conveyor belt 5 and a material blocking plate 6, and the material blocking plate 6 is placed close to the conveyor belt 5, and the pushing mechanism and the feeding mechanism Mechanisms are respectively arranged on both sides of the conveyor belt 5 and are oppositely arranged. The material blocking plate 6 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com