Braking castor

A technology of brake feet and brake plates, applied to casters, brake types, wheels, etc., can solve problems such as failure to brake in time, large inertia, damage, etc., and achieve reasonable structure, good safety, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

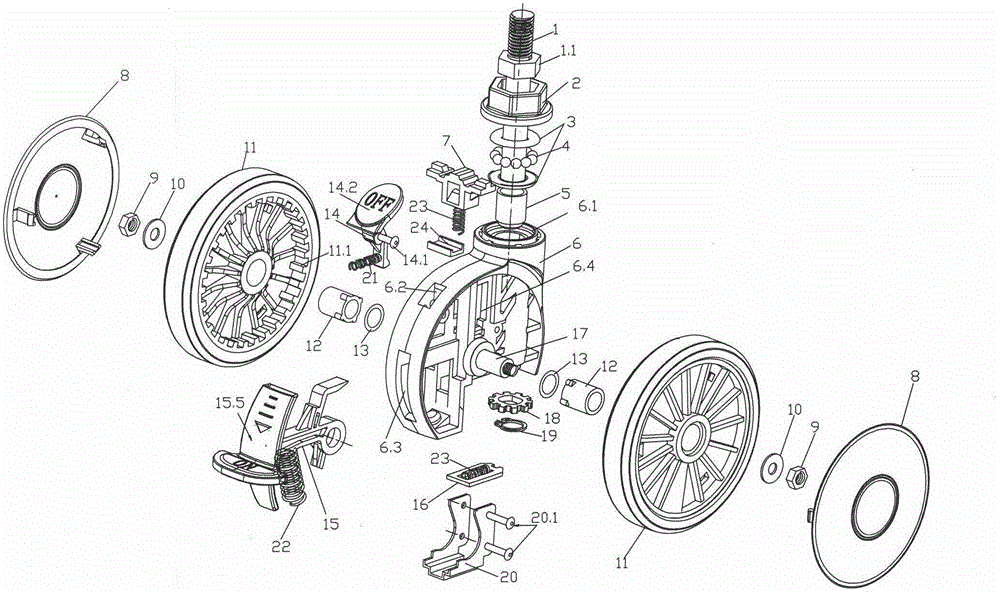

[0034] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described: as Figure 1-8 As shown, a brake caster of the present invention includes a wheel frame 6 with a transverse central axis 17, and the wheel frame 6 is vertically provided with a plunger chamber 6.1, and the plunger chamber 6.1 is provided with a plunger 1, and the wheel frame 6 has two The sides are respectively provided with side wheels 11 passing through the central axis 17, and also include:

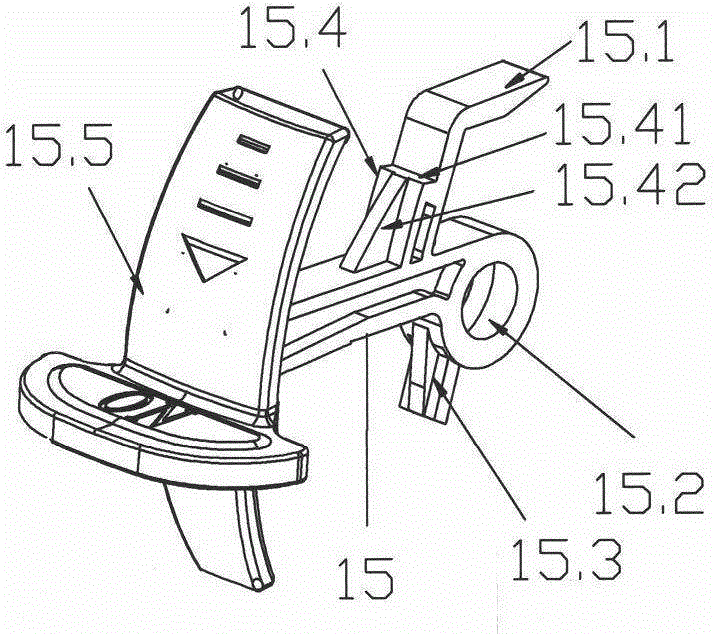

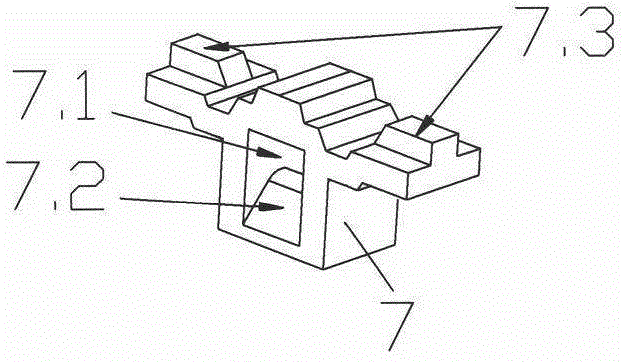

[0035] The first brake chainring 11.1, brake block 7, brake block spring 23, brake plate 15, brake plate spring 22, second brake chainring 18, brake pad 16, brake pad spring 23, brake pad bracket 20, unlock Plate 14 and unlocking plate spring 21.

[0036] The outer edge of the wheel frame 6 is respectively provided with an unlocking plate mounting hole 6.2 and a braking plate mounting hole 6.3.

[0037] The unlocking plate 14 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com