Positioning device and positioning method for cloth roller on tobacco shred storage cabinet

The technology of positioning device and cloth rolling roller, which is applied in the field of silk production in the tobacco industry, can solve the problems of blocked tobacco, loose cloth rolling, and no solution can be found, so as to ensure the quality of tobacco and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

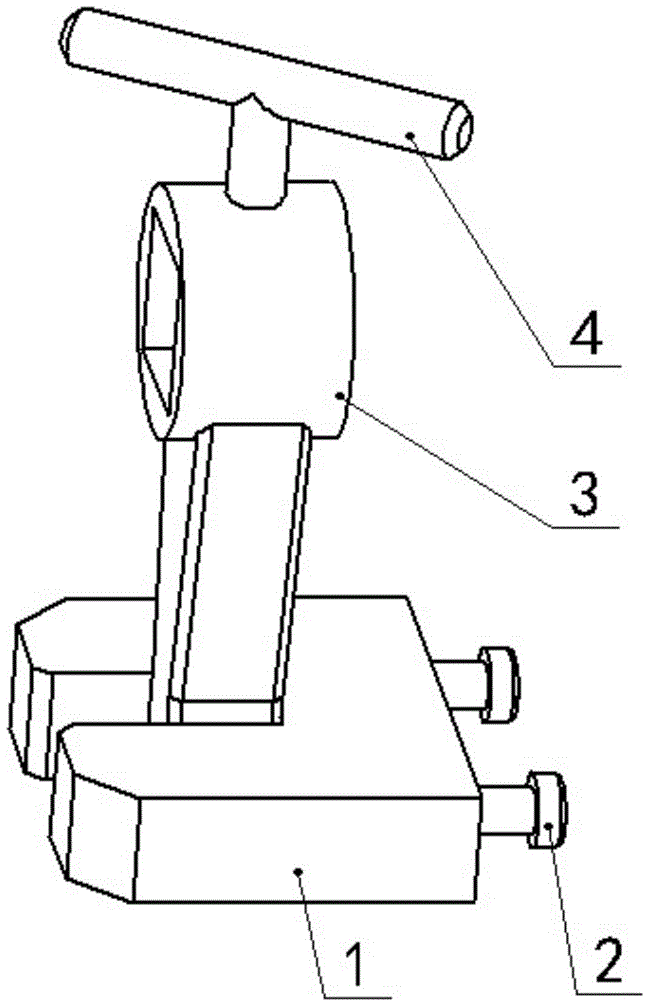

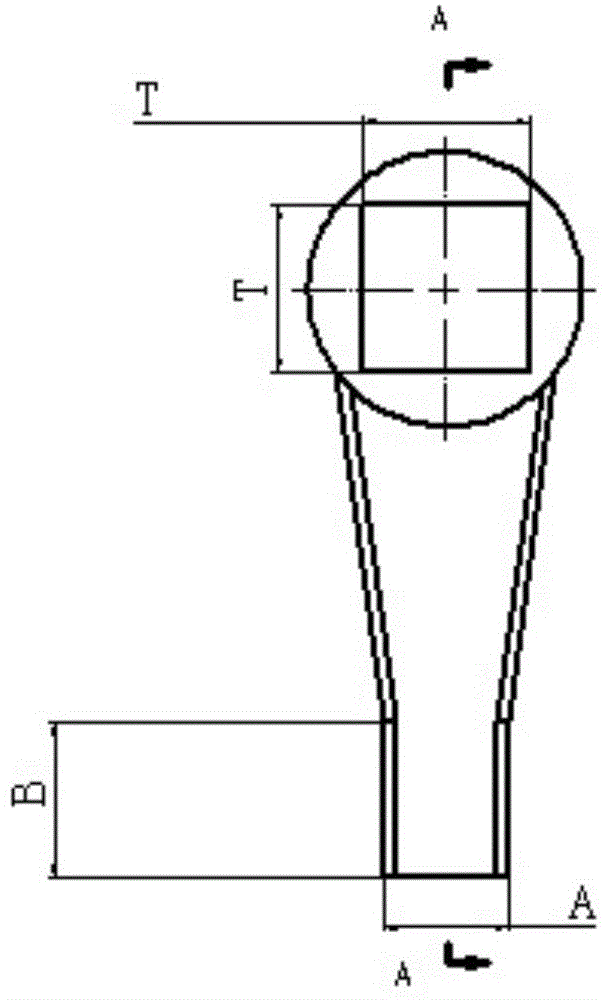

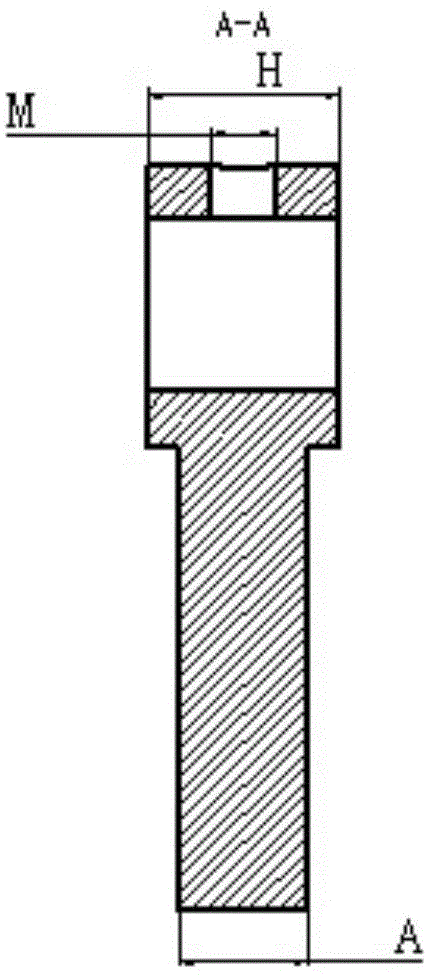

[0039] In the figure: positioning support 1, screw 2, positioning rod 3, fastening handle 4, wire storage cabinet wall 5, rotating shaft square head 6, cloth rolling roller 7, wire storage cabinet outlet 8, cover cloth 9.

[0040]The positioning device is mainly composed of a positioning support, a screw, a positioning rod and a fastening handle. The positioning support is installed on the wall of the wire storage cabinet through screws, and the positioning rod is installed on the square shaft of the cloth rolling roller through its square hole. Compress with the square head of the rotating shaft; design an open slot on the positioning support and design 2 threaded holes; the square shaft designed on the positioning rod can be inserted into the opening groove of the positioning support; the square hole designed on the positioning rod can be inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com