Scraper descaling device for electromagnetic chemical water treatment

A chemical water and scraper technology, used in electrochemical water/sewage treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of increasing labor costs, reducing treatment efficiency, and generating hard scaling on the plate surface, etc. problem, to achieve the effect of simple structure, low labor cost, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

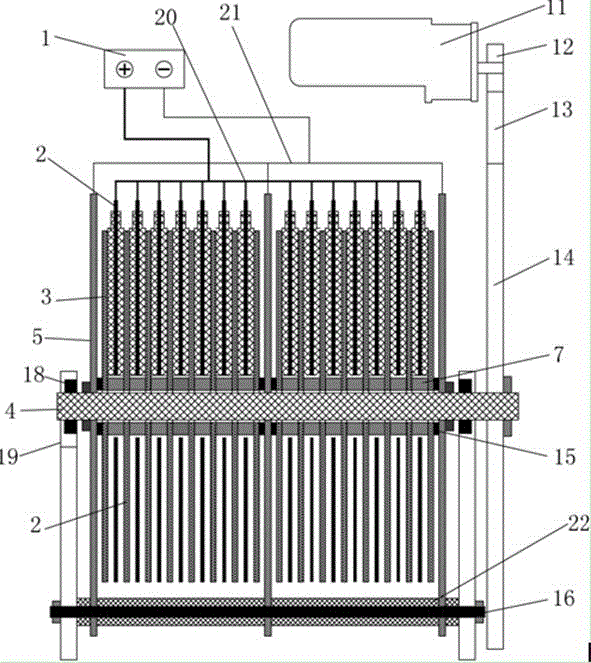

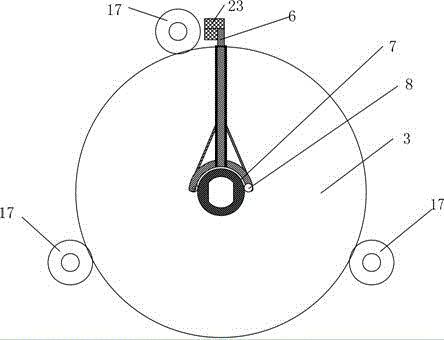

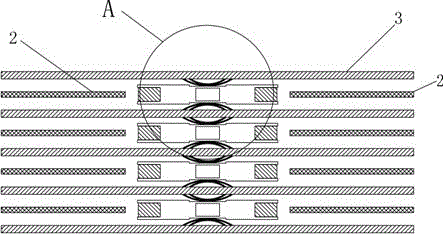

[0030] The number of positive electrode sheet 2, negative electrode sheet 3 and negative electrode conductive plate 5 is determined by the situation of concrete water treatment, present embodiment selects the number of negative electrode conductive plate 5 to be three, the number of negative electrode sheet 3 is eighteen, and the number of positive electrode sheet The number of 2 is nineteen pieces. One of the positive electrode sheets 2 is divided into two, and is arranged on both sides of the automatic laminating scraper descaling device. The number of multi-stage scraping springs can be determined according to actual needs, and three scraping springs can be used to achieve a better scraping effect. In this embodiment, two scraping springs are used. The number of 17 positioning guide columns can be determined according to actual needs, and can be two or four. In this embodiment, the number of 17 positioning guide columns is three, and the positioning effect is the best.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com