Fixed fastener for scaffold protective net

A protection net and fixing buckle technology, applied in the field of scaffolding protection net fixing fasteners, can solve the problems of large labor workload, cumbersome installation and fixing methods of workers, green, some blue or very few other colors, etc. Simple way to effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

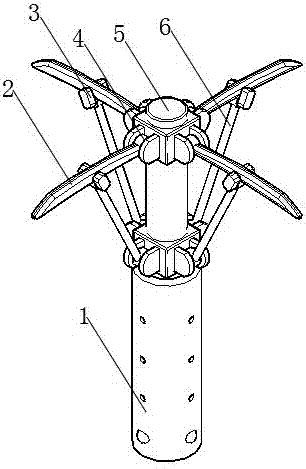

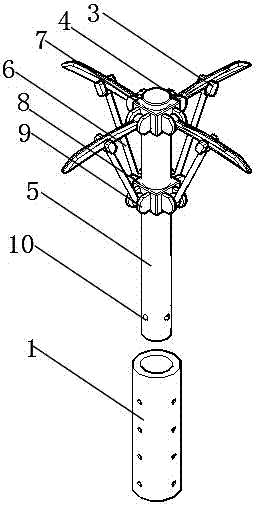

[0031] combined with Figure 1-9 As shown, a fixing fastener for a scaffold protective net includes a main rod 5, a fixed block 7 is fixed at any one end of the main rod 5, and an exposed ball 10 is arranged on the side wall of the other end of the main rod 5, and the fixed block The main rod 5 between 7 and the ball 10 is provided with a movable block 8 that can slide;

[0032] A support B4 is fixed on the fixed block 7, and the support B4 is hinged with a fixed rod 2 whose tail is provided with a bearing A11. The fixed rod 2 rotates on the support B4 along an axis perpendicular to the bearing A11. A support C3 is arranged on the rod 2;

[0033] A support A9 is fixed on the moving block 8, and the support A9 is hinged to any one end of the support rod 6 with bearings B12 at both ends, and the other end of the support rod 6 is hinged to the support C3. The supporting rod 6 drives the fixed rod 2 to rotate around the axis of the bearing A11;

[0034] One end of the main rod ...

Embodiment 2

[0038] In order to stably fix the ball 10 on the main rod 5, realize the expansion and contraction of the ball 10, and adjust the length of the main rod 5 in the casing 1, on the basis of the structure and principle of Embodiment 1, further combine the attached Figure 1-9 As shown, in this embodiment, the end of the main rod 5 away from the support B4 is provided with a cross-shaped through hole, the shape of the main rod 5 is cylindrical, and the ball 10 is arranged in the through hole on the main rod 5, A spring is fixedly connected between the two balls 10 on the same straight line, and the spring with the balls 10 connected at both ends is fixed in the through hole of the main rod 5 .

[0039] Structural principles:

[0040] Balls 10 are arranged at both ends of each of the cross-shaped through holes, and the angle between adjacent balls 10 is 90 degrees. The balls 10 are fixed on the main rod 5 by springs, and half of the volume of the balls 10 is exposed in the through ...

Embodiment 3

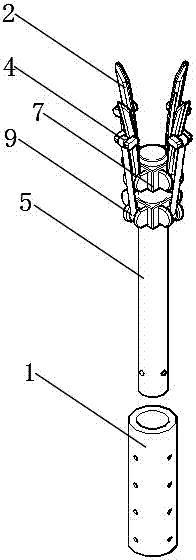

[0045] In order to fix the protective net better for the fixed rod 2, the support rod 6 on the moving block 8 drives the fixed rod 2 to move, on the basis of the structure and principle of embodiment 1, further combined with the attached Figure 1-9 As shown, in this embodiment, the end of the fixing rod 2 away from the support B4 is a pointed end, the fixing rod 2 is arc-shaped, and the shape of the supporting rod 6 is cylindrical.

[0046] Structural principles:

[0047] When the fixed rod 2 is opened, the arc-shaped fixed rod 2 on the main rod 5 forms a concave area, and the fixing ring of the protective net is more stably fixed on the main rod 5. The end point of the fixed rod 2 is the tip. It is convenient for the fixed rod 2 to be inserted in the fixed ring of the protective net.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com