Manufacturing method for cable of high temperature superconducting material

A technology of superconducting materials and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as superconducting material sheath rupture, and achieve the effect of preventing fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Since the Bi2212 superconducting material is expensive, it is necessary to save the superconducting wire as much as possible during the stranding process. During the twisting process, copper wires are used to butt it. In addition, the Bi2212 superconducting material is a ceramic material, which is relatively brittle. Excessive tension will cause the internal structure of the material to break and affect the performance of the material. During the stranding process, the tension is strictly controlled.

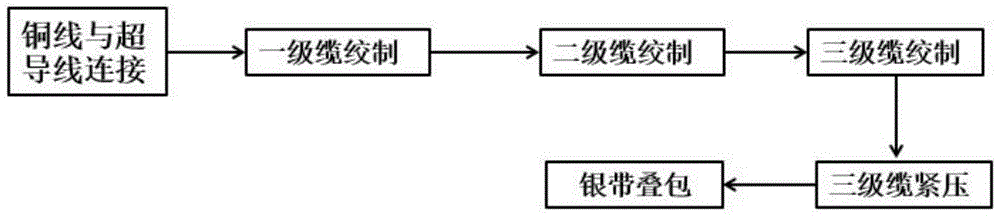

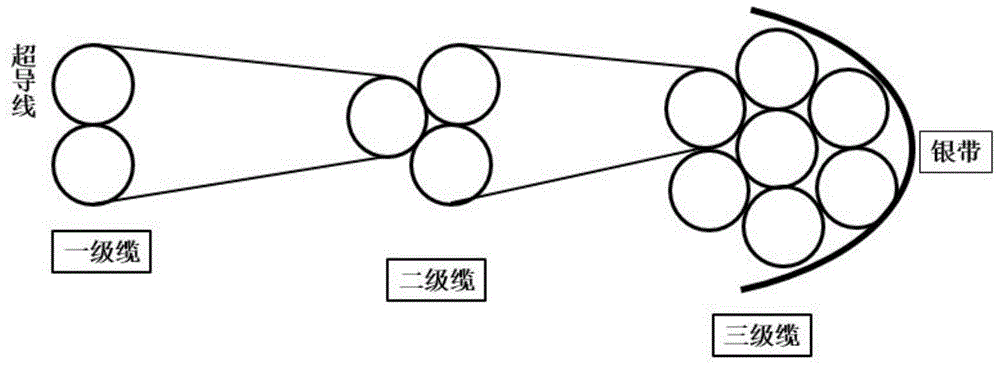

[0021] Such as Figure 1-3 Shown, a kind of manufacturing method of the cable of high temperature superconducting material, comprises the following steps:

[0022] Step 1: first connect the copper wire with the superconducting wire, and control the outer diameter of the joint within 2.0mm;

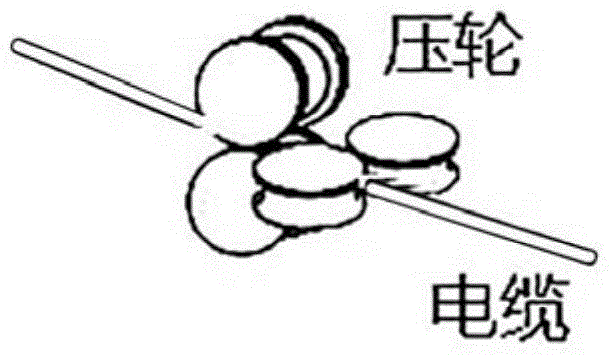

[0023] Step 2: Stranding of the first-level cable. Firstly, two superconducting wires are twisted on a single twisting machine. In order to ensure that the strands are not damaged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com