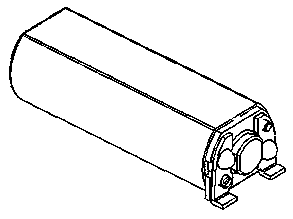

A fully enclosed micro motor with low noise and high vibration

A fully enclosed, micro-motor technology, applied in the field of motors, can solve the problems of severe vibration, noise, and unsuitability for mass production in motors, and achieve the effect of reducing noise and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

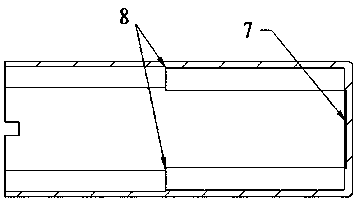

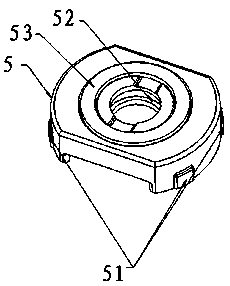

[0033] Such as figure 2 As shown, the casing in the present invention is a cuboid structure in the shape of a bucket, with one end open and the other end closed. The main purpose of this type of casing in the present invention is to completely seal the end cover assembly, stator assembly, and rotor assembly of the entire motor. Inside the casing, the exterior of the entire motor forms a whole, and one of its functions is to facilitate installation. A positioning concave hole is arranged in the center of the sealing end surface of the housing, and the concave hole is used for placing the oil storage sealing gasket. The inner diameter of the concave hole and the outer diameter of the bearing bracket have strict coaxiality requirements. A part of the height of the washer is embedded in the bearing bracket, and another part is embedded in the concave hole of the casing, and the height of the gasket protruding from the bearing bracket is equal to the height of the concave hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com