Preparation method of cheddar cheeses

A technology of cheddar cheese and leavening agent, which is applied in the field of preparation of cheddar cheese, can solve the problems of less research and achieve the effect of improving flavor, increasing speed and enhancing milk aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Cheddar cheese added with Lactobacillus plantarum CGMCC No.12227

[0040] 1. Preparation of Lactobacillus plantarum CGMCC No.12227 direct input working starter.

[0041] Plantarum CGMCC No.12227 was inoculated into sterilized MRS liquid medium according to the inoculation amount of 2% (v / v), and cultured at 37°C for 18-24h, until the number of viable Lactobacillus plantarum CGMCC No.12227 reached 10 8 More than cfu / mL, 4000rpm, 10min, centrifuge at 4°C, wash the precipitate twice with PBS buffer solution of pH 7.0, add lyoprotectant, adjust the cell concentration to 10 9 cfu / mL, after mixing, carry out vacuum freeze-drying treatment, and the freeze-dried product is the Lactobacillus plantarum CGMCC No.12227 direct-injection working starter.

[0042] 2. Production of cheddar cheese containing Lactobacillus plantarum CGMCC No.12227 direct-input working starter

[0043] The production process of cheddar cheese is as follows: pasteurize the raw milk and cool...

Embodiment 2

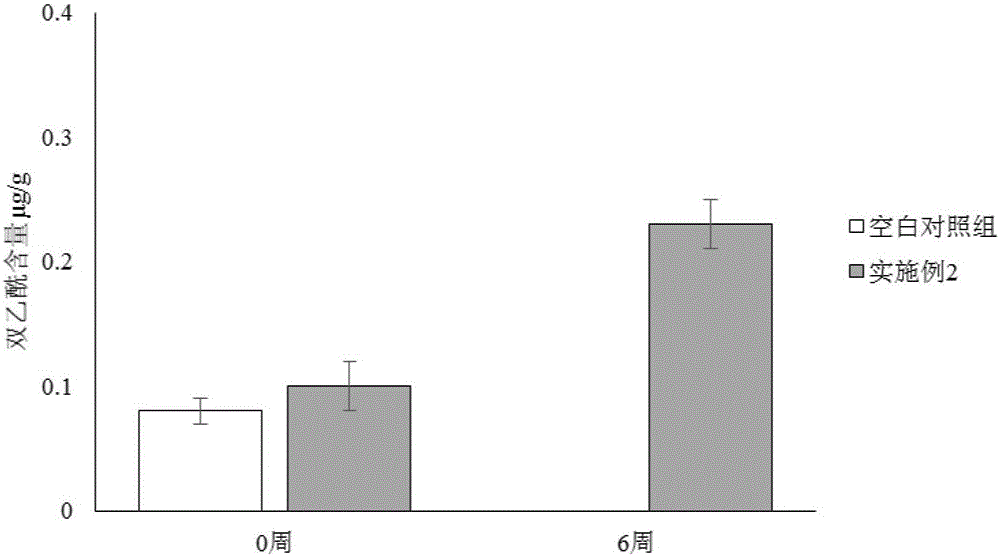

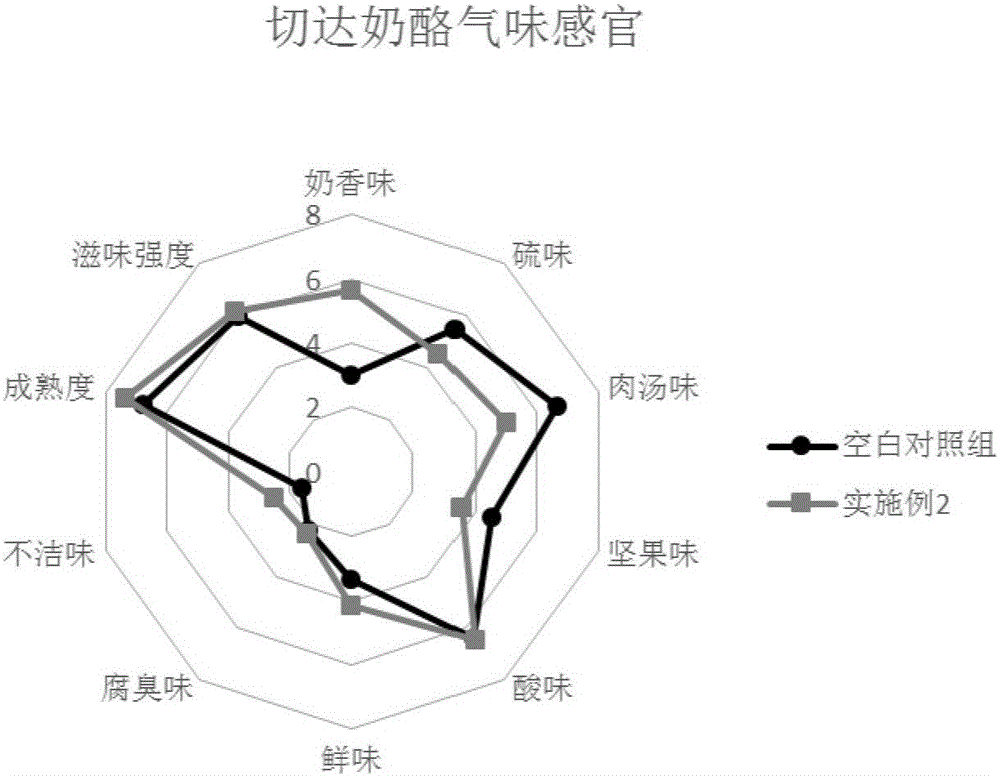

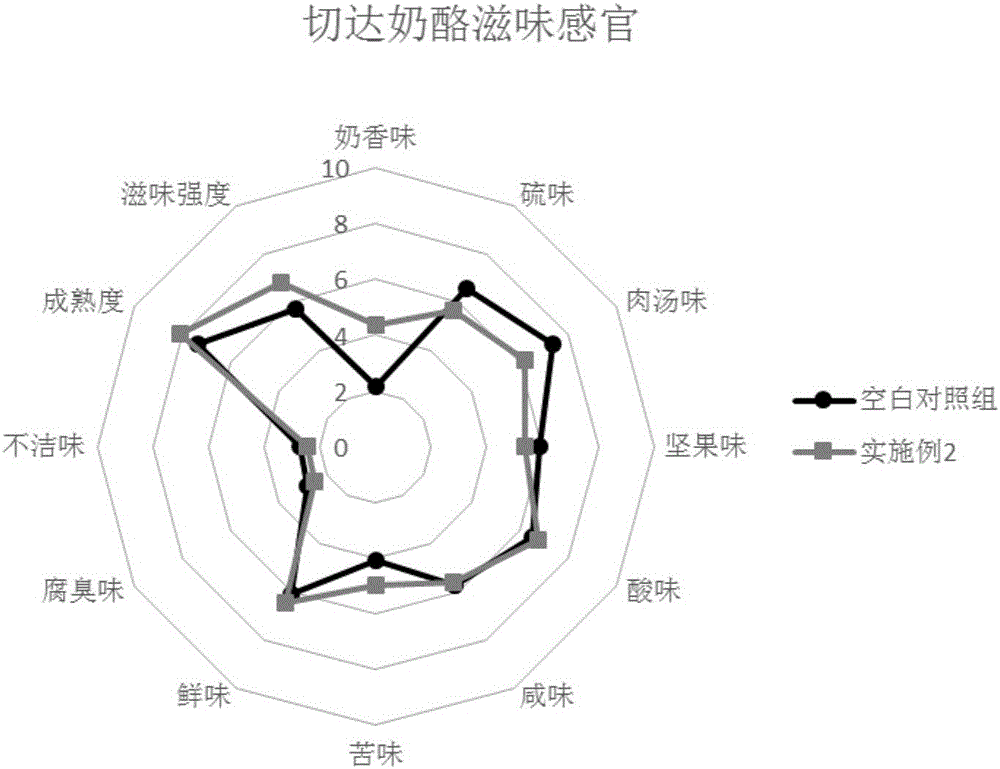

[0061] Embodiment 2: Cheddar cheese added with Lactobacillus plantarum CGMCC No.12227

[0062] 1. Activation of Lactobacillus plantarum CGMCC No.12227

[0063] Purification and isolation of MRS plate: aseptically operate the inoculation loop to pick Lactobacillus plantarum CGMCC No.12227, streak on the sterilized MRS plate, place the plate in a 37°C incubator for 48 hours, and pick a single colony for microscopic examination , to achieve the purification and separation of strains.

[0064] Activation of the original strain: Take out the refrigerated strain stored in the -80°C refrigerator, put it in an ice bath until the bacterial liquid melts, take 100 μL of the bacterial liquid and inoculate it into 5 mL of sterilized MRS liquid medium, and incubate at 37°C for 18 hours. Streak, culture in solid MRS medium at 37°C for 48 hours, pick a single colony and inoculate it into sterilized MRS liquid medium, activate and culture for three generations, and then carry out subsequent e...

Embodiment 3

[0086] Embodiment 3: Cheddar cheese added with Lactobacillus plantarum CGMCC No.12227

[0087] (1) Pretreatment of raw milk

[0088] After the standardized raw milk is pasteurized at 68°C for 30 minutes, it is rapidly cooled to 32°C

[0089] (2) Addition of starter

[0090] The starter strain was activated in sterilized 10% skim milk medium at 30°C for 12 hours, added to the raw milk according to the addition amount of 2% (v / v), and stirred evenly;

[0091] (3) Addition of auxiliary starter

[0092] Activate Lactobacillus plantarum CGMCC No.12227 in sterilized 10% skim milk medium at 30°C for 12 hours, add 3% (v / v) to the raw milk, stir evenly, and let it stand until the pH Reduced by about 0.2;

[0093] (4) Addition of rennet

[0094] Add rennet in an amount of 0.002% (wt / wt), stir evenly, and curd for a period of time;

[0095] (5) Cut curd, heat up and remove whey

[0096] After the curdling is completed, it can be cut, then stirred slowly, and after the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com