Automatic stirring-frying device for hotpot condiment production system

A production system and technology of hot pot base material, applied in food science and other directions, can solve the problems of high product failure rate, error, raw material flavor and pigment damage, etc., to improve production efficiency, ensure quality, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

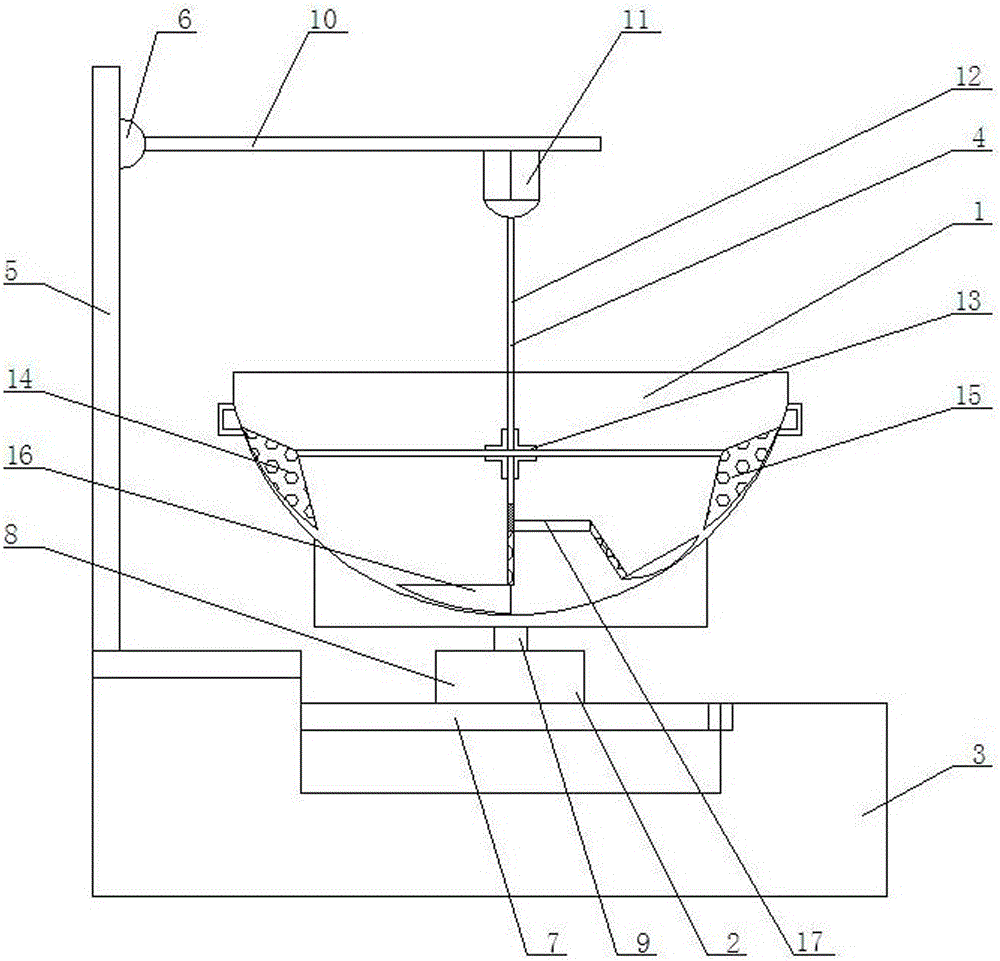

[0018] As shown in the figure, an automatic stir-frying device for hot pot bottom material production system includes a pot body 1, a rotating device 2, a base 3, a stirring device 4, and a fixing frame 5. The bottom end of the pot body 1 passes through the rotating device 2. The device is installed on the base 3, and the left side of the base 3 is equipped with a fixed frame 5; the stirring device 4 is fixed on the upper right side of the fixed frame 5 through the electric rotating head 6; a groove is arranged in the middle of the top of the base 3; the rotating The device 2 is composed of a connecting base 7, a rotating motor 8, and a rotating shaft 9. The rotating motor 8 is mounted on the connecting base 7 through a bolt fixture, the upper end of the rotating motor 8 is connected to the rotating shaft 9, and the bottom end of the pot body 1 is connected through the rotating shaft 9; The connecting seat 7 is installed inside the groove, and the upper right end is connected...

Embodiment 2

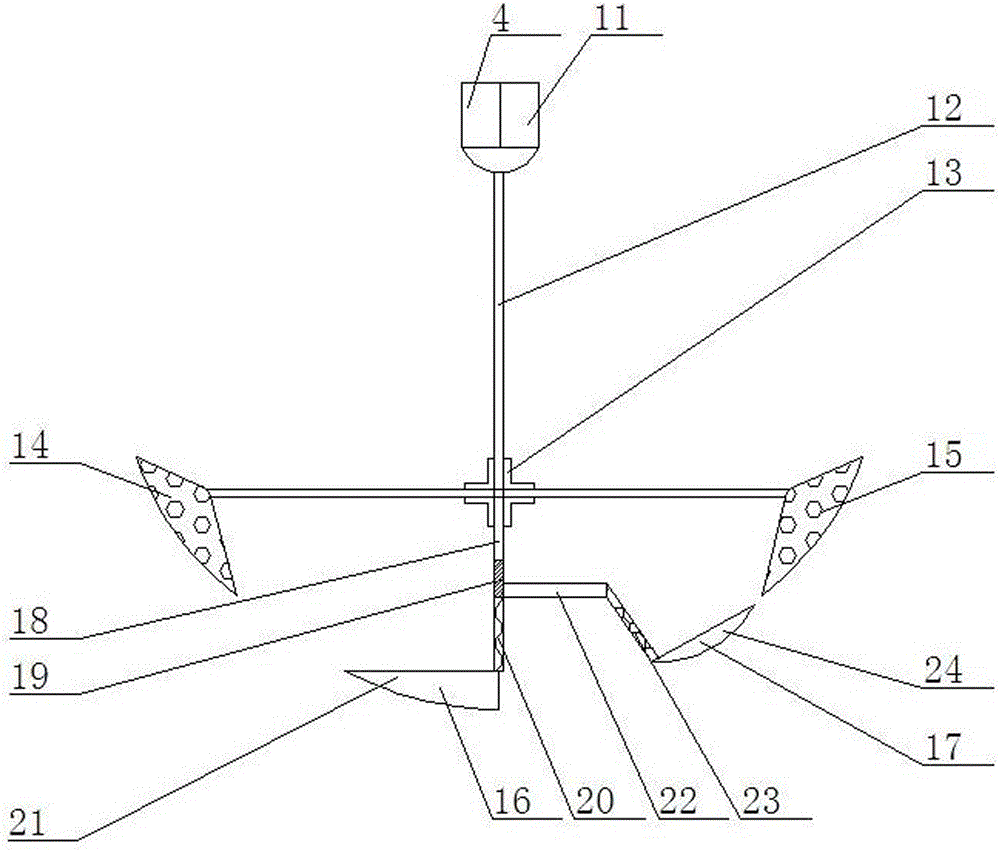

[0020] As shown in the figure, the stirring device 4 is composed of a fixed plate 10, a stirring motor 11, a stirring shaft 12, a cross 13, a first stirring mechanism 14, a second stirring mechanism 15, a third stirring mechanism 16, and a fourth stirring mechanism 17. Composition; the left end of the fixed plate 10 is connected to the electric rotating head 6, the right side of the bottom end is equipped with a stirring motor 11, the lower end of the stirring motor 11 is connected to the stirring shaft 12, and the bottom end of the stirring shaft 12 is connected to the first stirring mechanism 14, the second Stirring mechanism 15, the 3rd stirring mechanism 16, the 4th stirring mechanism 17 of the 3rd stirring mechanism 16 top right devices.

Embodiment 3

[0022] As shown in the figure, the first stirring mechanism 14 is composed of a cross bar and a scraper; the right end of the cross bar is connected to the cross 13, and the left end is fixedly connected to the scraper through bolts and nuts; the structure of the second stirring mechanism 15 is similar to that of the first A stirring mechanism 14 has the same structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com