Multi-purpose material pyrolysis catalytic tank

A catalytic tank, multi-purpose technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of slow heating speed, troublesome operation, poor work reliability, etc., and achieve acceleration Fast, easy to operate, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

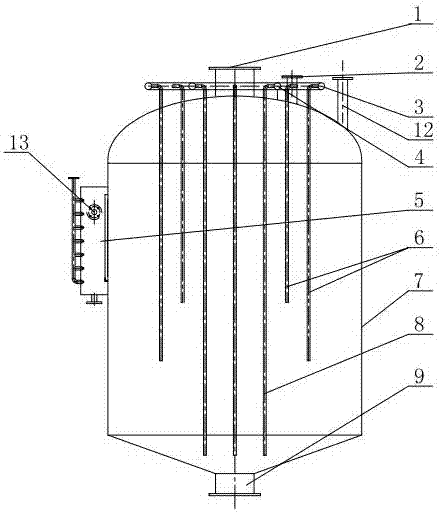

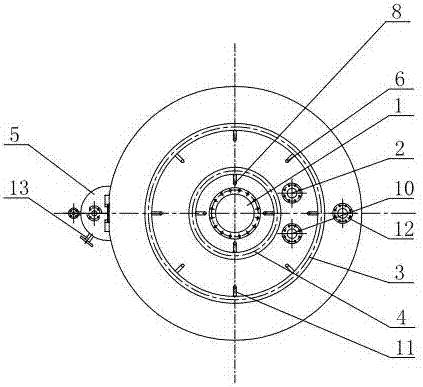

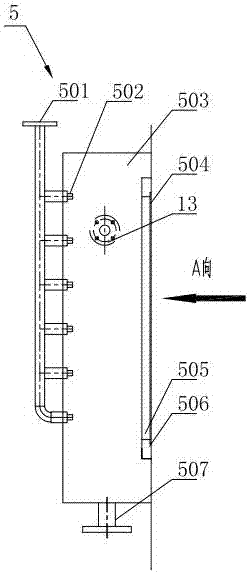

[0025] like figure 1 and figure 2 As shown, the multi-purpose material pyrolysis catalytic tank of this embodiment includes a tank body 7, and the top surface of the tank body 7 is equipped with an inner ring heating tube 4 and an outer ring heating tube 3 in the same horizontal plane, and the inner ring heating tube 4 A plurality of built-in heating tubes 8 for the inner ring are installed at even intervals on the top, and a plurality of built-in heating tubes 6 for the outer ring are installed at even intervals on the outer ring heating tube 3, and the built-in heating tubes 8 for the inner ring and the built-in heating tubes 6 for the outer ring are installed at even intervals. Both extend into the inside of the tank body 7; a feed inlet 1 is installed in the middle of the top of the tank body 7, and an exhaust pipe 2, a flash steam o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com