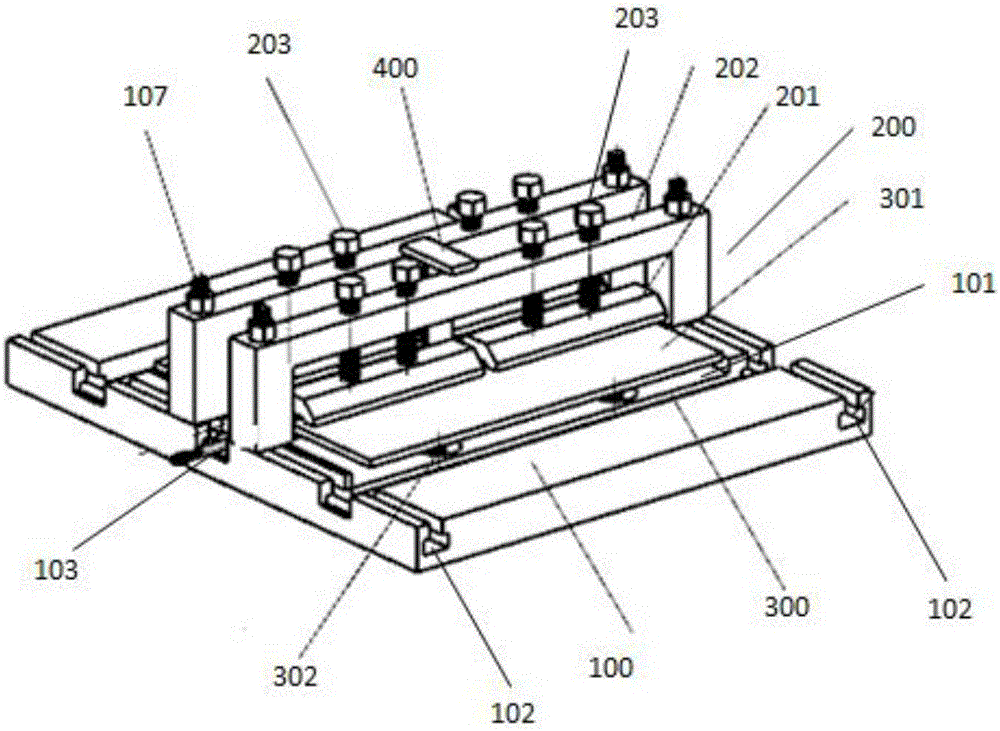

Weldment clamp

A weldment fixture and weldment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the weld gap is not easy to control accurately, the back weld is prone to oxidation, and the back molding is not easy to control and other problems, to achieve the effect of firm fixation, anti-oxidation, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

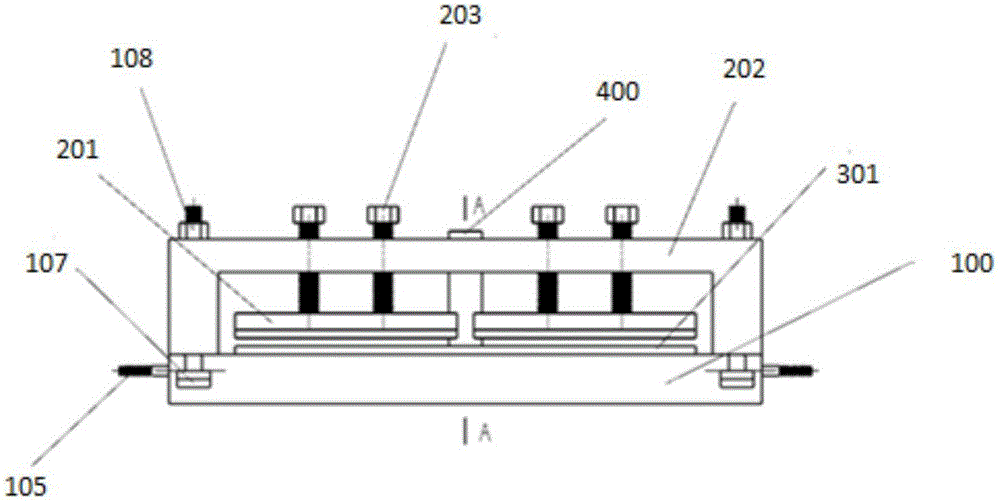

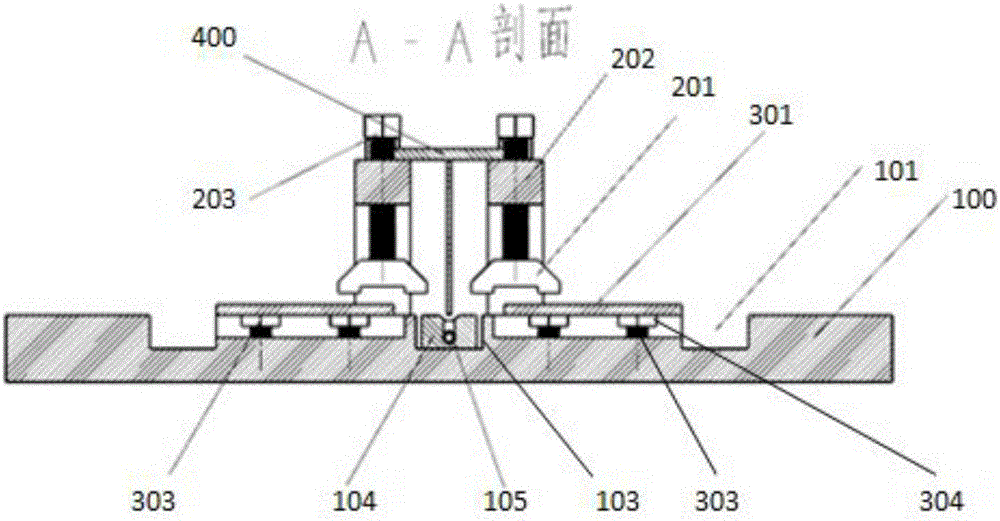

Embodiment 1

[0042] For the butt welding experiment of welded parts with the same thickness, place the spacer in the rectangular groove of the base plate, adjust the backing plate adjustment device on both sides of the welding fixture, so that the backing plate is at the same height, and place the welding parts to be welded separately. On the backing plates on both sides, align the joint of the weldment with the center of the groove of the spacer, accurately control the size of the gap reserved between the welds through the gap ruler, place the piano key type pressure plate on the top surface of the weldment, adjust The lateral position of the pressing plate makes it above the piano key type pressing plate, and the fixing bolts on the pressing plate frame are tightened to fix the weldment under the piano key type pressing plate.

Embodiment 2

[0044] For the lap welding experiment of welded parts with the same thickness, by adjusting the height difference of the backing plate adjustment device on both sides to be equal to the thickness value of the sample, the welded parts to be welded are respectively lapped on the backing plates on both sides, and the keyboard type The pressing plate is placed on the weldment, the position of the pressing plate frame is adjusted so that it is above the piano key type pressing plate, and the fixing bolts on the pressing plate frame are tightened to fix the weldment under the piano key type pressing plate.

Embodiment 3

[0046] For the butt welding experiment of welded parts with different thicknesses, place the spacer in the rectangular groove of the substrate, adjust the backing plate adjustment device on both sides so that the height difference of the backing plate is equal to the difference in the thickness of the weldment, and weld the required welding The parts are placed on the backing plates on both sides, so that the joints of the welded parts are aligned with the center of the groove of the pad, and the gap size reserved for the weld is precisely controlled by the gap ruler. The position of the frame makes it be on the top of the piano key type pressing plate, and the fixing bolts on the pressing plate frame are tightened to fix the weldment under the piano key type pressing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com