Screw feeding and conveying mechanism with double sliding blocks and double cams

A transmission mechanism, double cam technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of optimizing space, reducing noise, and reducing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below with reference to accompanying drawing and in conjunction with embodiment, describe the present invention in detail:

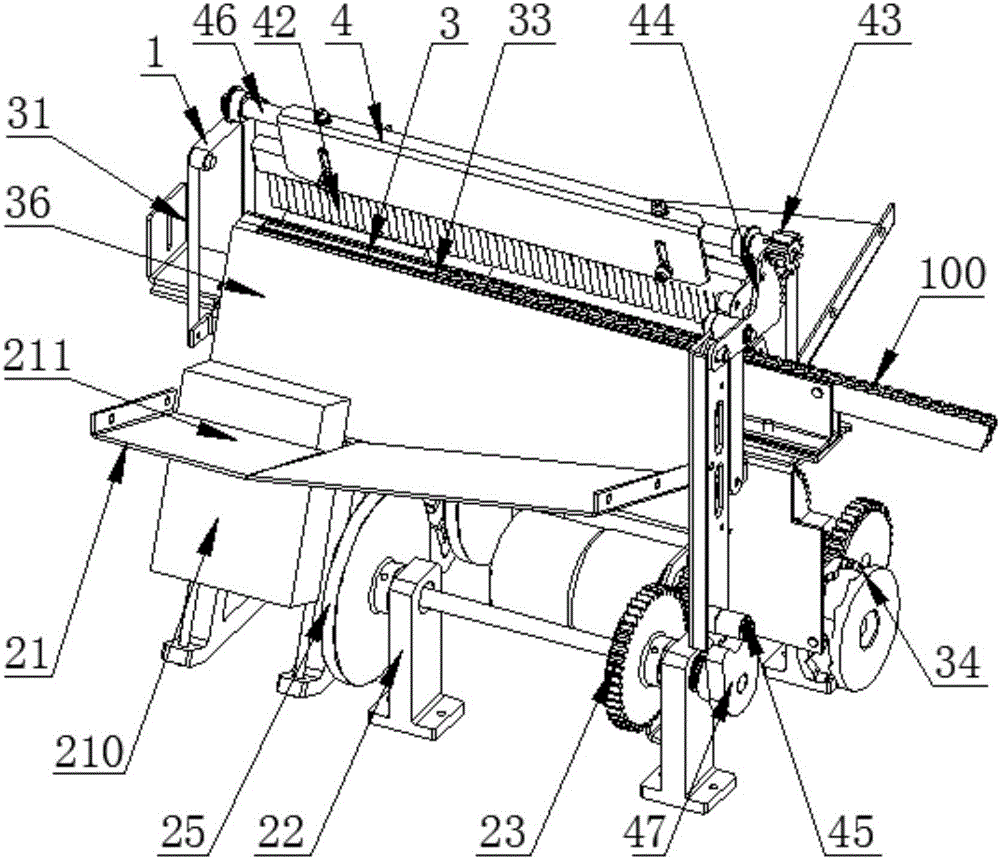

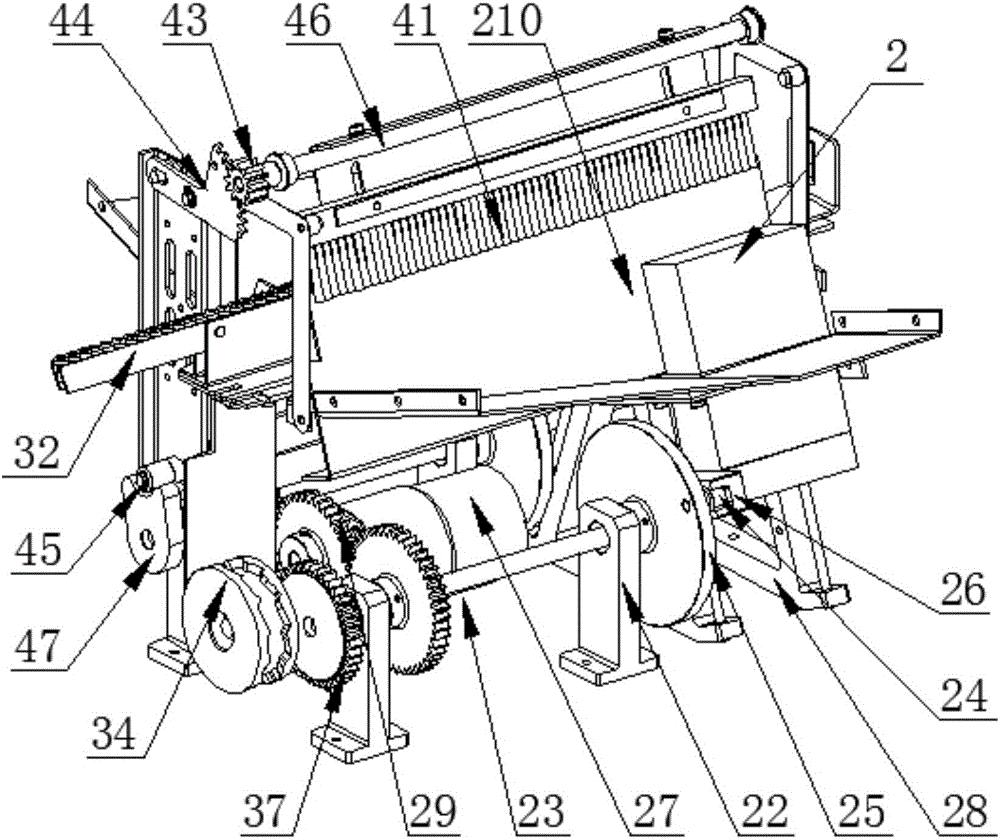

[0038] Such as Figure 1-Figure 8 What is shown is an embodiment of the present invention. The double-slider double-cam screw feeding transmission mechanism provided by this embodiment includes a frame 1, a feeding mechanism 2, a feeding mechanism 3 and a sweeping mechanism 4. Figure 1-8 Let’s describe each constituent mechanism in detail, and the drawings of each description simplify some components in order to see the internal structure and details more intuitively.

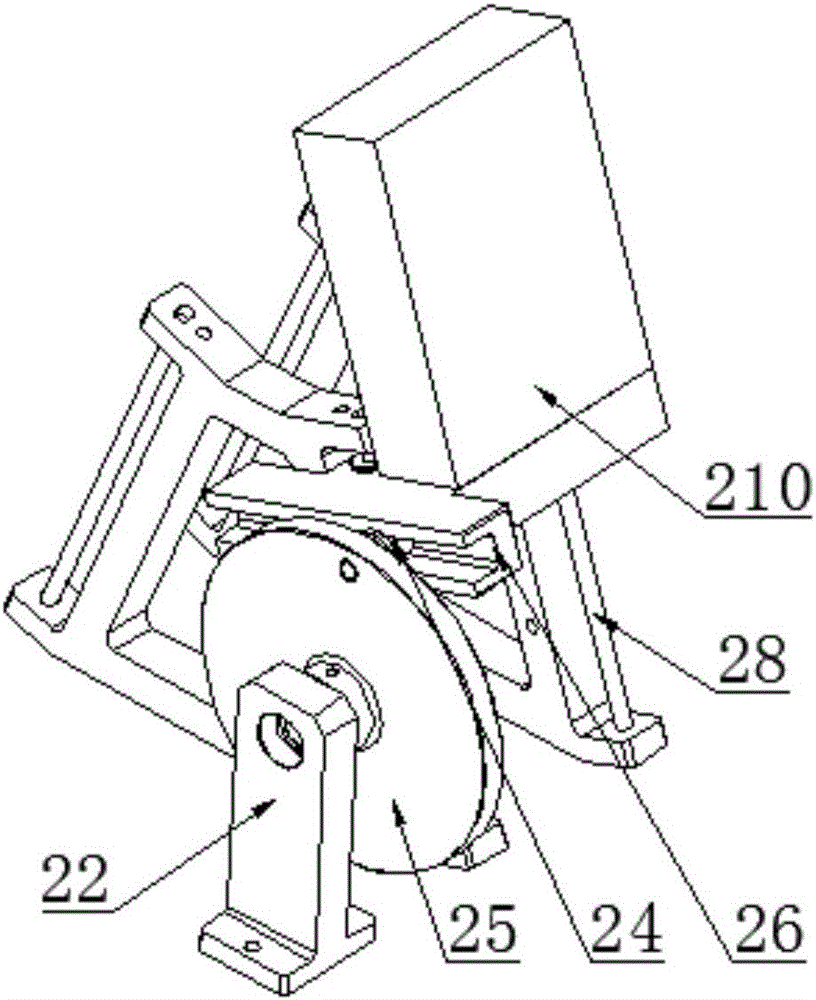

[0039] Such as Figure 1-Figure 3 As shown, wherein the feeding mechanism 2 includes a screw lift push plate 210 that sends the screw 100 to the feed mechanism 3. The top of the screw lift push plate 210 is an inclined inward slope, and the screw lift push plate 210 is arranged on the bottom plate 21 of the screw bin. , and one is provided on both sides of the feeding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com