Connecting device capable of quickly changing working head

A connecting device and working head technology, which is applied in the field of connecting devices for quick replacement of working heads, can solve the problems of complex structure of related connecting parts, falling off of working heads, increased processing difficulty and production cost, etc., so as to eliminate the possibility of locking failure , good transmission torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

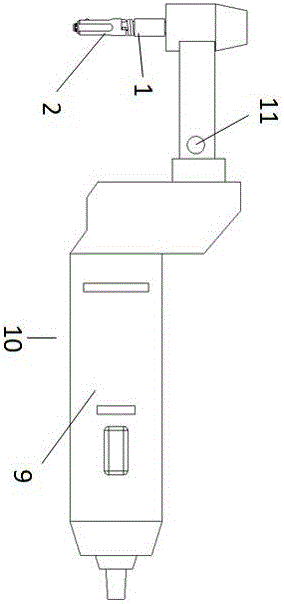

[0033] Such as Figures 1 to 3 As shown, an electric tool 10 includes a tool housing 9 and a motor installed in the tool housing 9, a reduction mechanism, a switch, etc., wherein the output end of the drive unit formed by the motor and the reduction mechanism is connected to a connecting device.

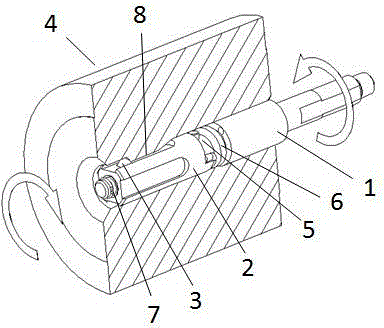

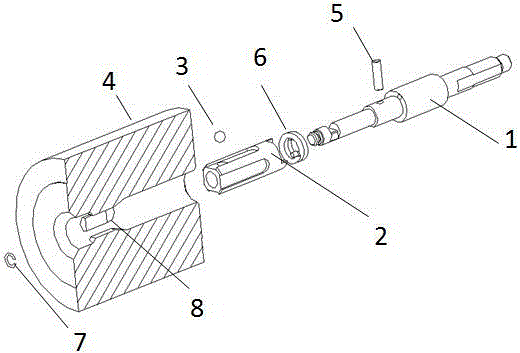

[0034] The connection device is used to connect with the working head 4 with the inner hole convex rib 8, which includes a fixed rotary sleeve 2 that can be inserted into the working head 4, and a drive shaft that is sleeved in the fixed rotary sleeve 2 to provide rotational power 1.

[0035] The outer wall of the fixed rotary sleeve 2 is evenly provided with four grooves in the circumferential direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com