Rapid assembling movable type template system of straddle type monorail transit rail beam

A straddle-type monorail and rail beam technology, which is applied to mold fixtures, mold auxiliary parts, ceramic molding machines, etc., can solve problems such as unfavorable transportation, uneconomical, and movement of finished rail beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of this patent is described below through specific examples, and those skilled in the art can easily understand other advantages and effects of this patent from the content of this specification. This patent can also be implemented or applied through other different specific implementation methods, and the details in this specification can also be modified or changed based on different viewpoints and applications without departing from the spirit of this patent.

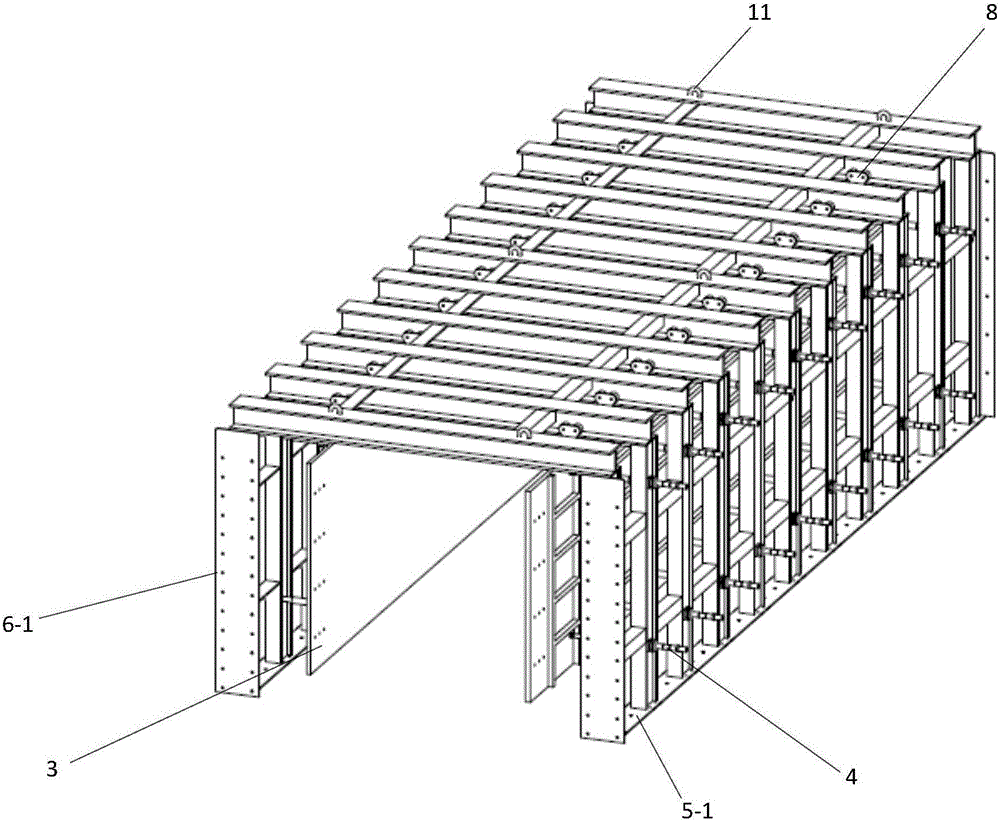

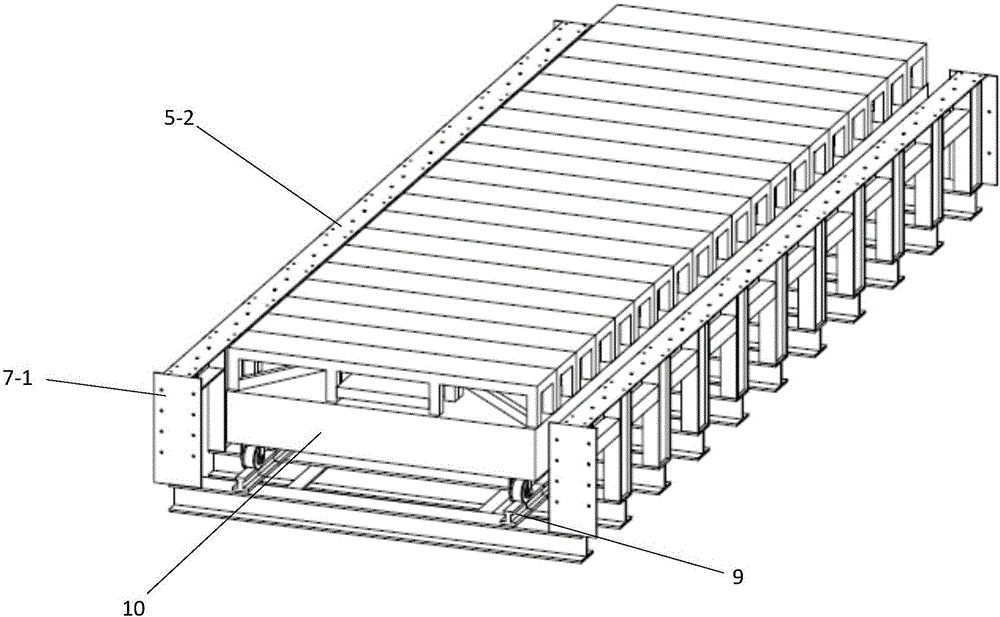

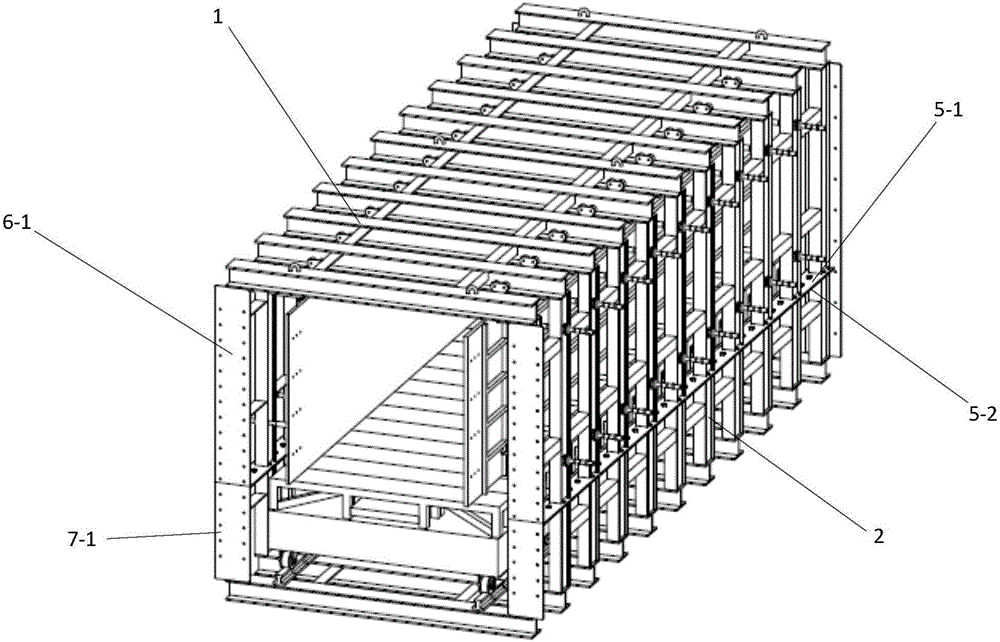

[0016] Embodiment A certain city plans to build a 15km straddle type monorail traffic line, and the maximum span of the single track girder is 30m. The straddle type monorail traffic rail girder is used to quickly assemble the mobile formwork system to produce the track girder, so as to improve the utilization rate of the formwork. To achieve the purpose of saving costs and shortening the construction period. The length of each segment is L=12m, and a total of 3 track beams are used to assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com