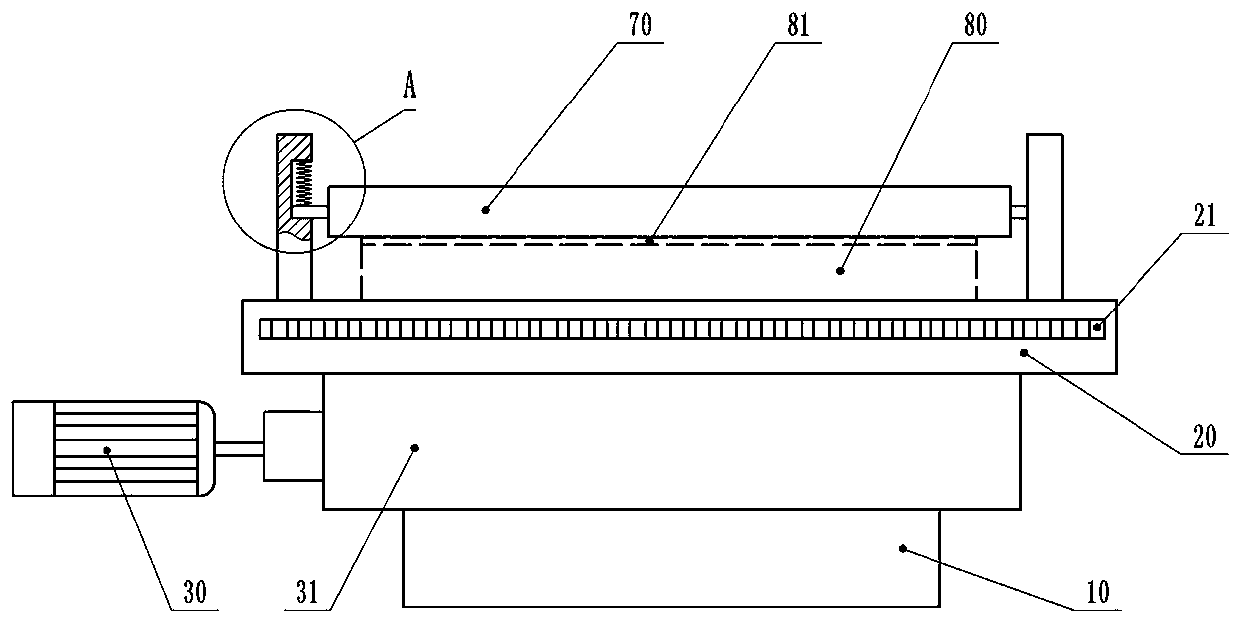

Device for coating furniture panels

A board and film coating technology, which is applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve the problem of difficult discharge of air bubbles on the contact surface, and achieve the effect of convenient film lamination process and better lamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

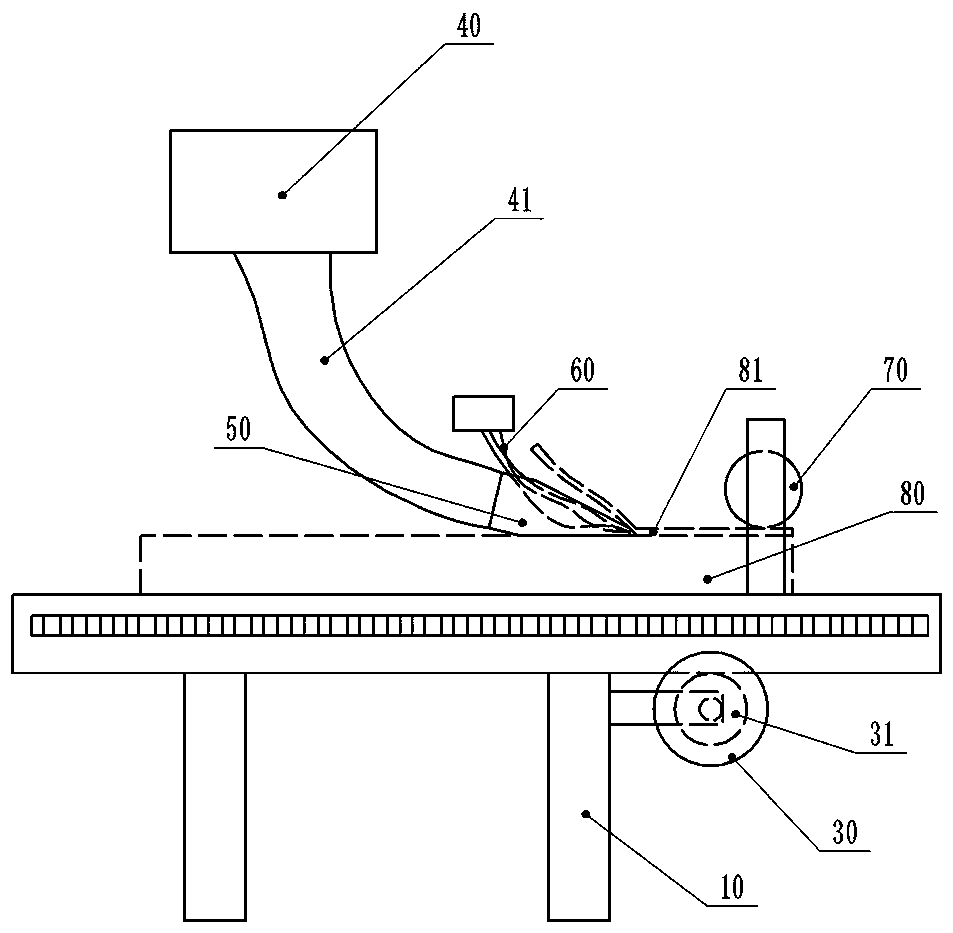

[0024] The difference from Embodiment 1 is that, in this embodiment, there are ventilation pipes on both sides of the suction nozzle 50 , and the air outlet of the ventilation pipe is flush with the lower opening 53 .

[0025] When this device is used to coat the furniture plate 80, the heated gas is continuously fed into the air pipe first, and the heated gas enters the front end of the suction nozzle 50 from the air outlet of the air pipe, and under the action of the suction nozzle 50, The heated gas will surround the contact surface between the film 81 and the furniture plate 80, so that the heated gas will fill the contact surface between the film 81 and the furniture plate 80, and uniformly heat the lower surface of the film 81, so that the film 81 remains At an appropriate temperature, the coating effect of the furniture board 80 is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com