A device for laminating and heating materials

A silicone heating, multi-layer material technology, applied in the direction of lamination devices, lamination, layered products, etc., can solve the problems affecting the quality of multi-layer circuit board substrates, not giving circuit implementation plans, and existing pressure, etc. The effect of small error, strong resistance to external impact and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

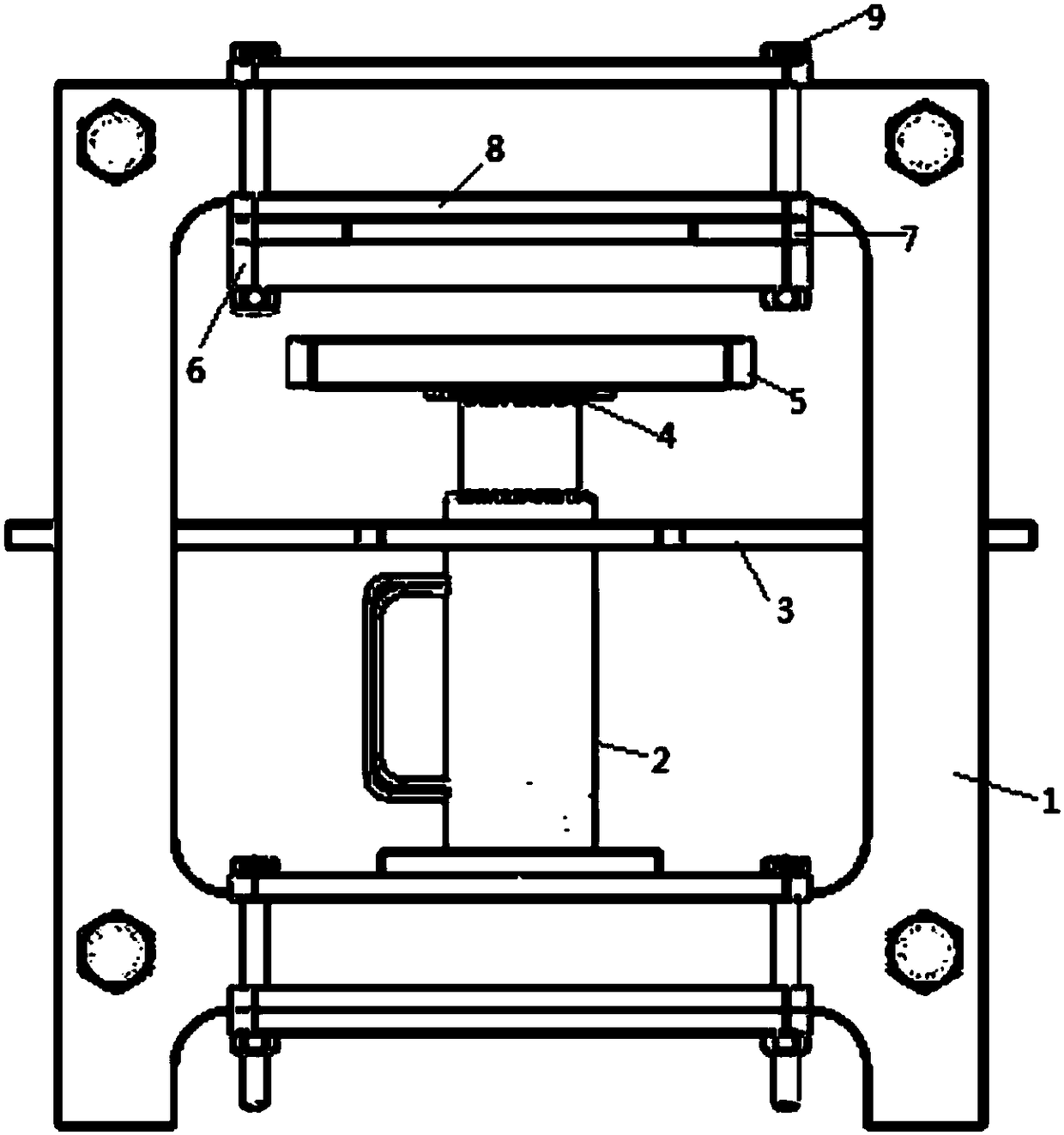

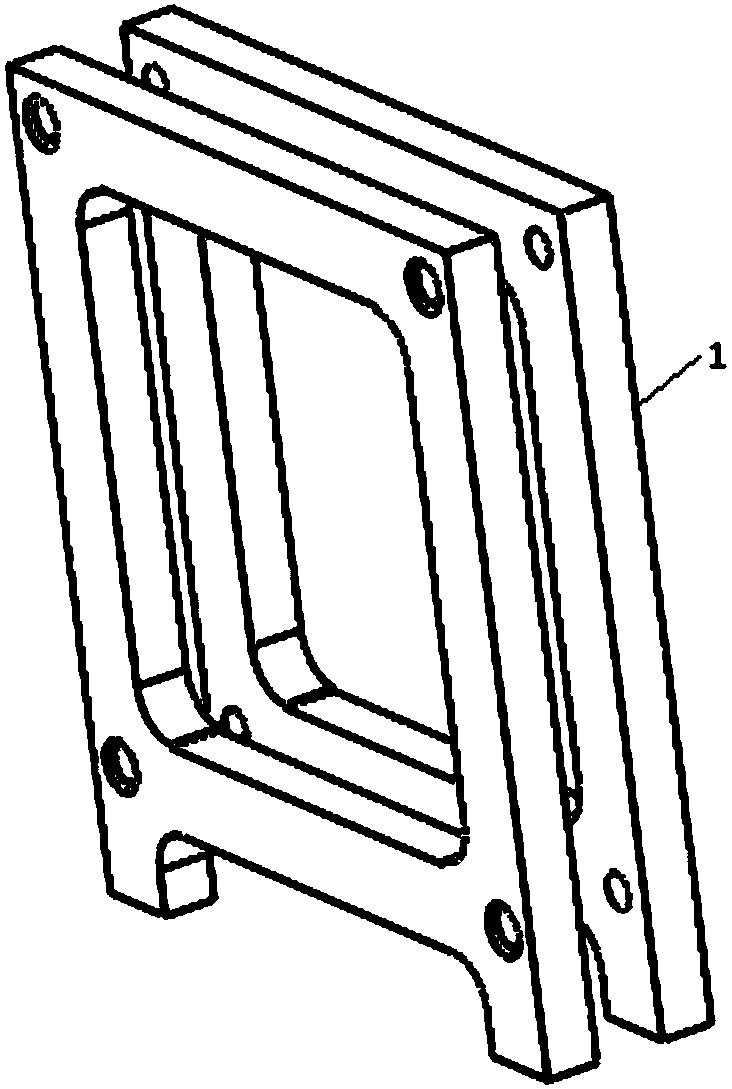

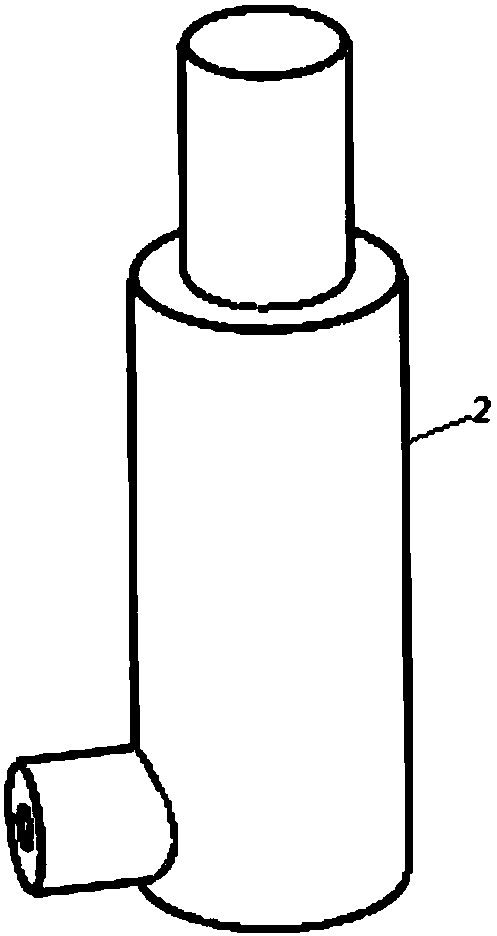

[0040] like figure 1 As shown, it is a device capable of laminating and heating materials in a preferred embodiment of the present invention, including: an integrated support 1, a jack 2, a fixing plate 3, a soft gasket 4, a lower pressure head 5, an upper Indenter 6, grooved metal plate 7, quartz plate 8, silica gel heating sheet 9, wherein:

[0041] The upper and lower parts and the left and right parts of the integrated support 1 are an integral frame structure;

[0042] The bottom of the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com