Defect-resistant folding mark type energy absorption box

A technology for energy-absorbing boxes and defects, which is applied in the field of anti-defect crease-type energy-absorbing boxes, and can solve problems affecting energy absorption efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

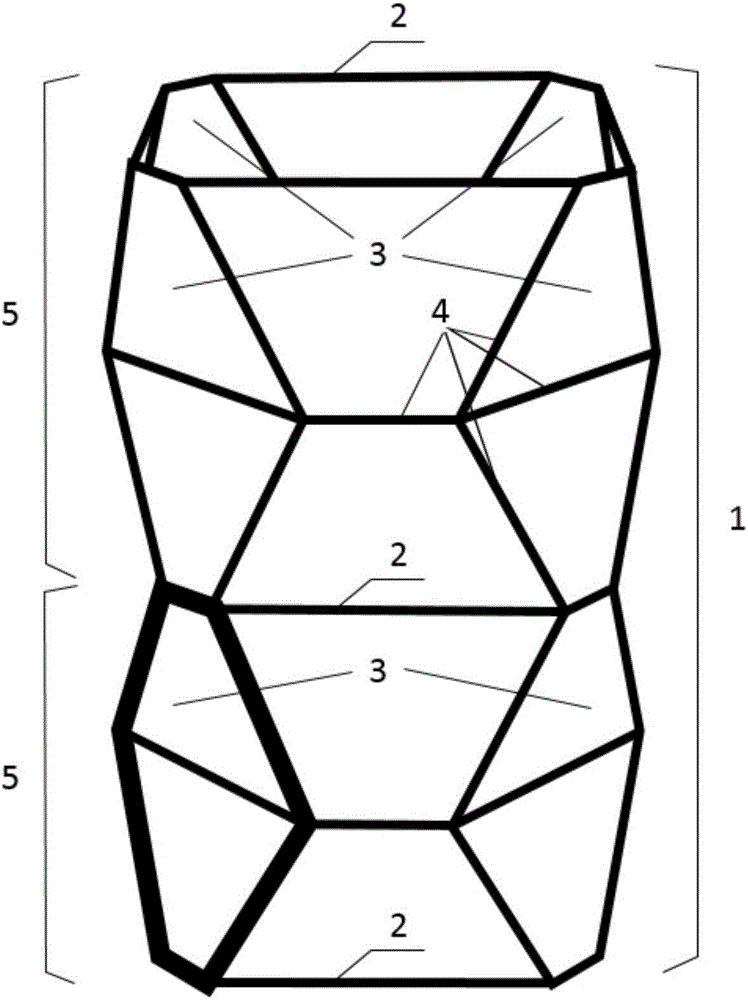

[0018] Example 1: figure 1 An embodiment of an octagonal cross-section anti-defect crash crash box.

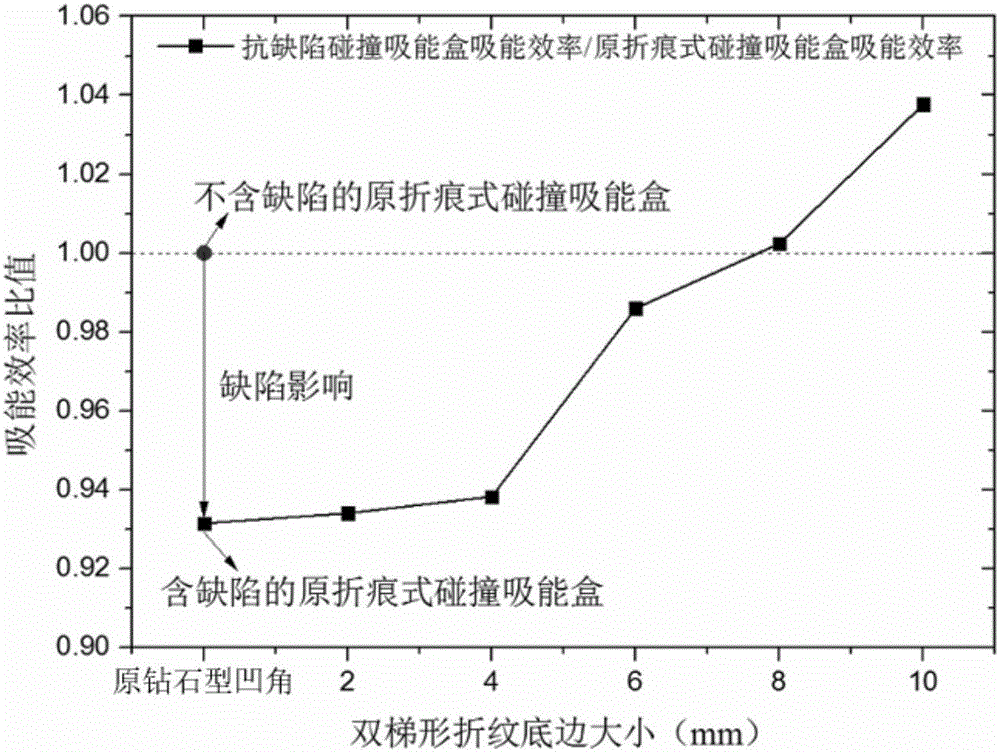

[0019] The so-called octagonal cross-section anti-defect collision crash box 1 means that the cross-section 2 of 1 is octagonal. figure 2 It is a schematic diagram comparing the energy absorption efficiency of the original crease-type energy-absorbing box of the octagonal cross-section anti-defect collision energy-absorbing box under the condition of defects. It can be found in the figure that the energy-absorbing efficiency of the anti-defect impact energy-absorbing box is higher than that of the original crease The type crash box has a greater improvement, and it increases with the increase of the bottom edge of the double trapezoidal concave angle.

[0020] The octagonal cross-section anti-defect collision energy-absorbing box can be made with a suitable processing technology. Considering that the pipe wall of the present invention is a expandable structure, it can be ma...

Embodiment 2

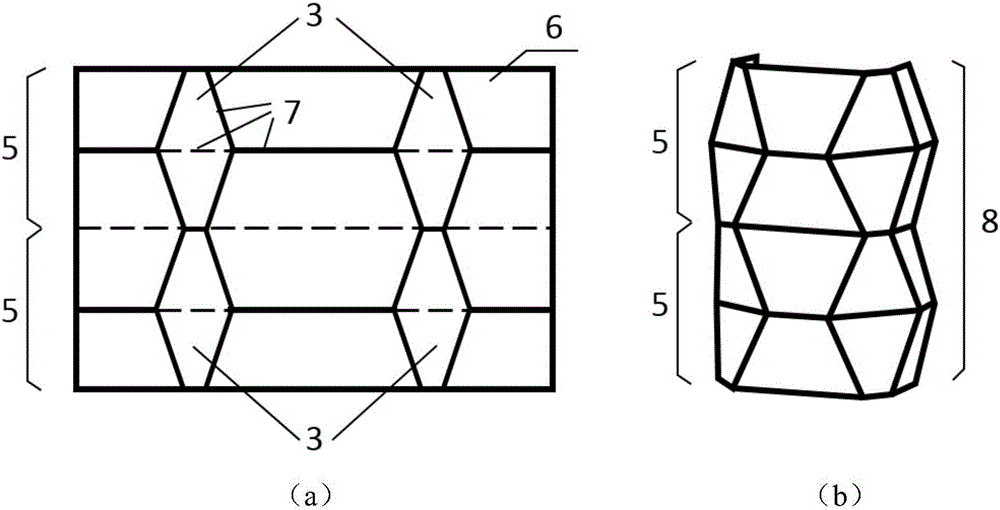

[0021] Example 2: Figure 4 (a) An implementation of the hexagonal cross-section anti-defect crash crash box.

[0022] The so-called hexagonal cross-section anti-defect collision crash box means that the cross-section of the crash box 9 is hexagonal. Due to the expandable structure of the tube wall, the processing technology of the defect-resistant crash-absorbing box with hexagonal cross-section and octagonal cross-section is similar, except that the hexagonal shape can only be assembled and welded by one-third of the crash-absorbing box made. Similarly, the lengths of the units 10 along the axial direction can also be different, and the size and shape of the double trapezoidal units 3 in the units 10 can also be different.

Embodiment 3

[0023] Example 3: Figure 4 (b) is an embodiment of the anti-defect crash crash box with dodecagonal cross-section.

[0024]The so-called dodecagonal cross-section anti-defect collision crash box means that the cross-section of the crash box 11 is dodecagonal. Due to the expandable structure of the tube wall, the processing technology of the anti-defect collision crash box with dodecagonal cross-section and octagonal cross-section is also similar, except that the dodecagonal cross-section can be divided into one-half, one-third , or one-sixth of the energy-absorbing box is assembled and welded. Similarly, the lengths of the units 12 along the axial direction can also be different, and the size and shape of the double trapezoidal units 3 in the units 12 can also be different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com