Cambered surface type rubber belt track iron tooth assembly with limit structure

A technology of limit structure and rubber crawler, applied in crawler vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as scrapping crawler, achieve the effect of saving materials, reducing fuel consumption and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

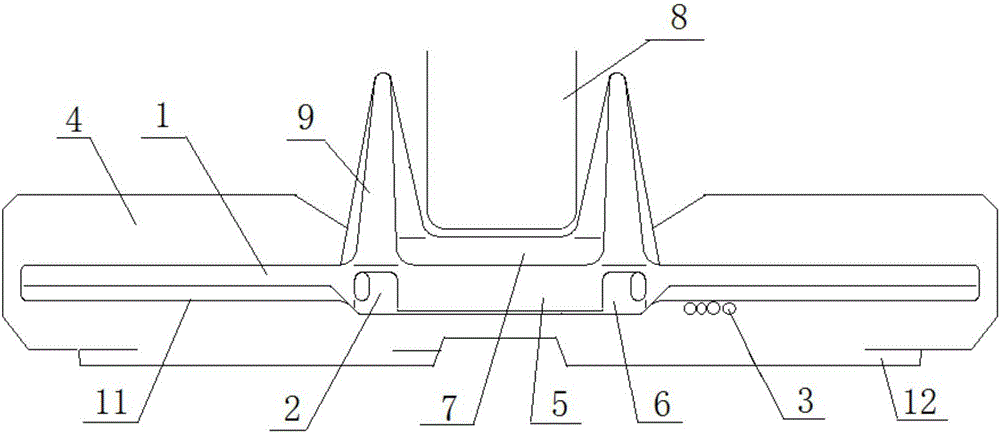

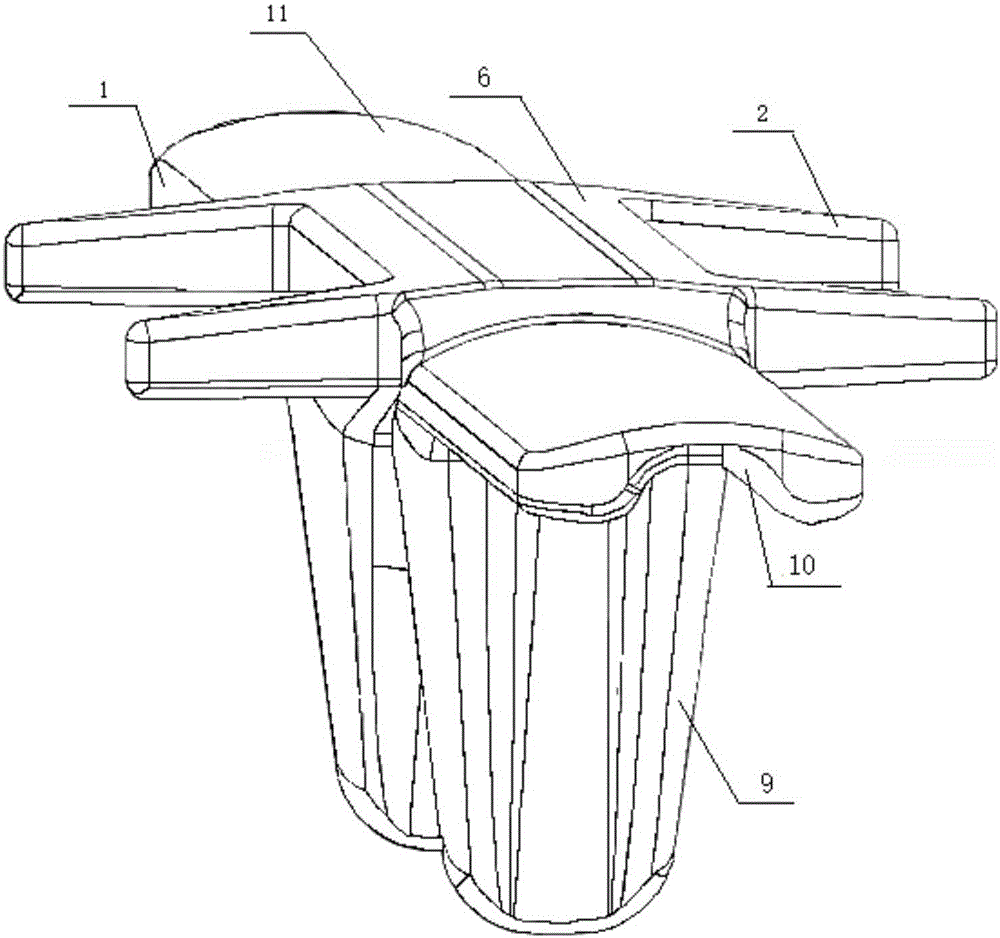

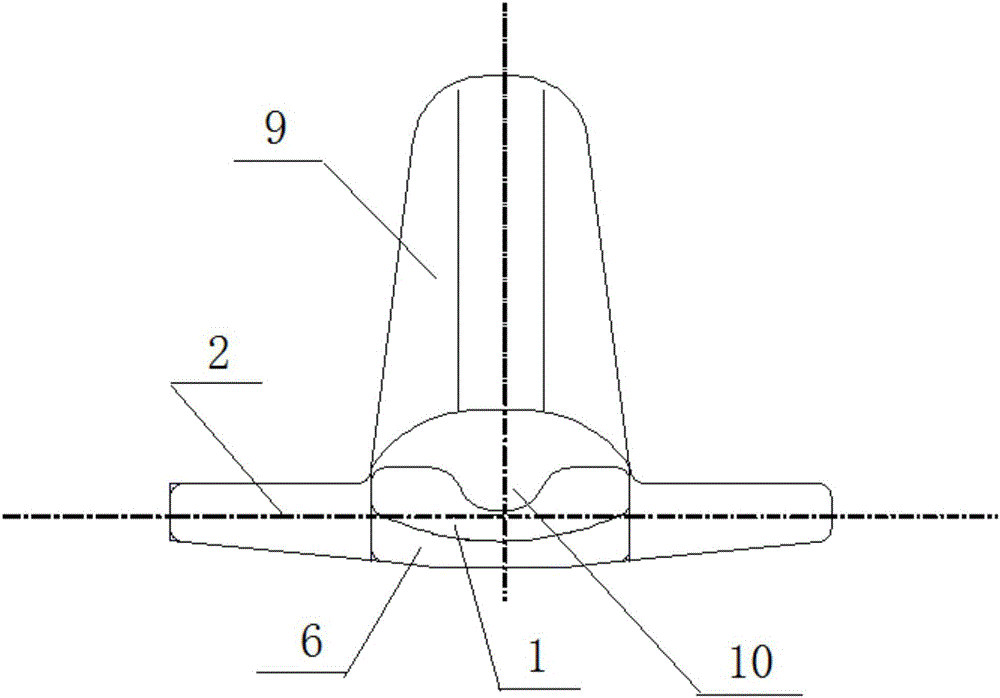

[0033] Embodiment 1: as attached figure 1 As shown, the two wings of the tooth plate 1 have a pair of protruding anti-skid teeth 2 respectively. The shape of the outer surface is partially nested with the shape of the two inner surfaces of a pair of anti-skid teeth 2 of the other wing. The front lateral middle part of the tooth plate 1 is convex and its two sides have an outer edge arc-shaped surface 11 extending laterally and bending toward the two wings. , There are two upwardly protruding inducing teeth 9 on the back of the tooth plate 1, and the distance between the two inducing teeth 9 is the same as the distance between the two rows of anti-slip teeth 2 .

[0034] In the foregoing, the anti-slip teeth 2 are nested between two adjacent tooth plates 1 arranged longitudinally along the track to form an overlapping degree greater than or equal to 2mm.

[0035] In the foregoing, the extension length of the anti-skid teeth 2 is not greater than the longitudinal width of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com