Balance vehicle wheel fixing structure and balance vehicle

A technology of fixed structure and balance car, applied in the direction of motor vehicles, bicycles, two-wheeled bicycles, etc., can solve the problems of occupying space, easy movement, easy rolling of wheels, etc., and achieve the effect of small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

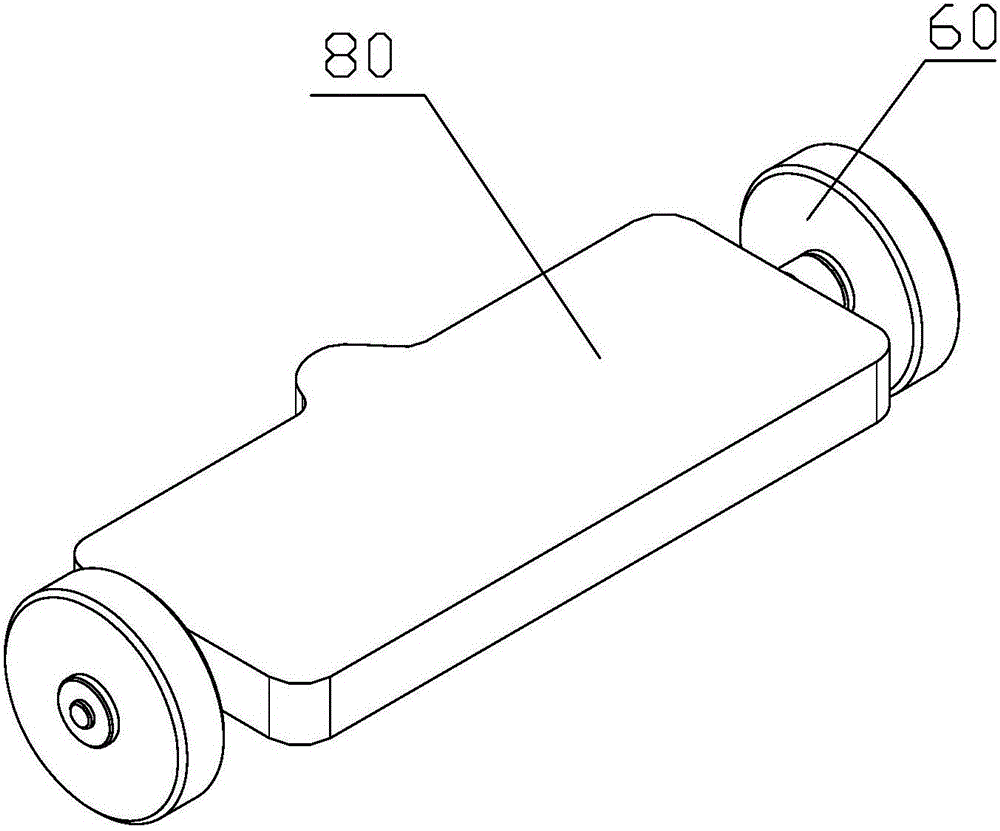

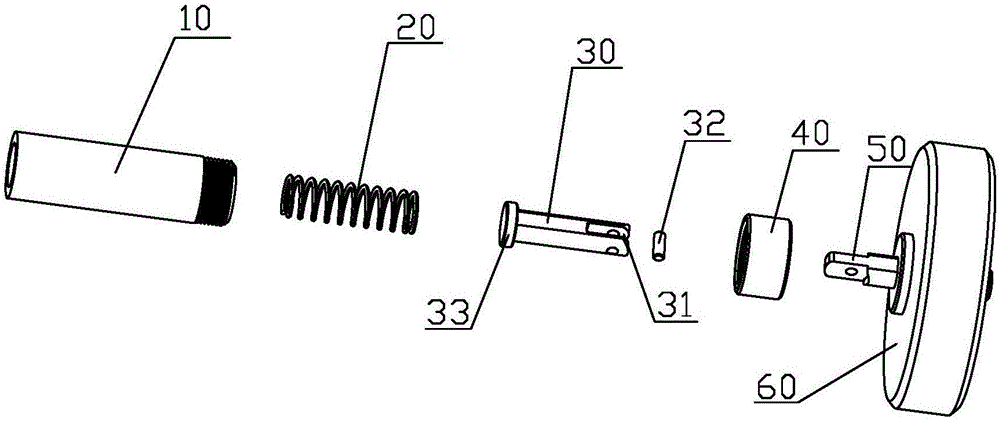

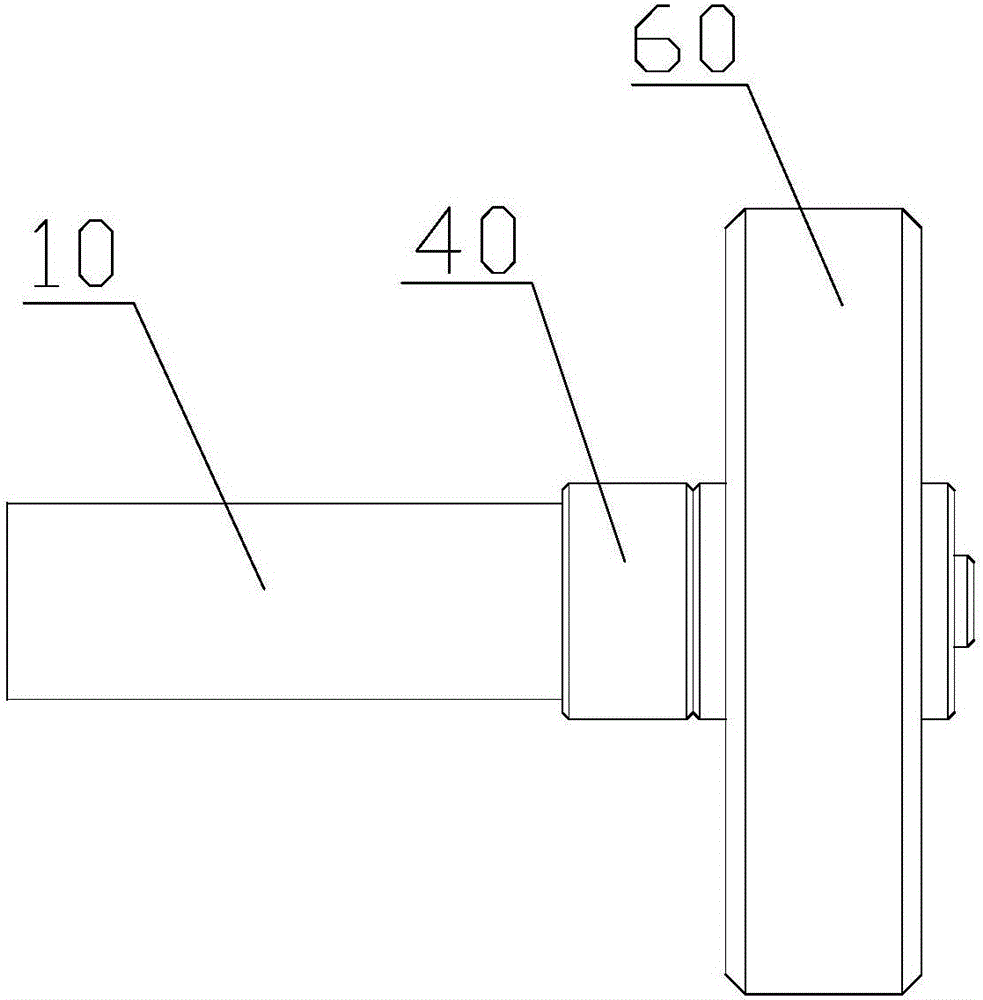

[0031] The invention discloses a balance car. The balance car includes a car body; the car body is provided with a wheel fixing structure. The wheel fixing structure includes a hollow pipe body; the hollow pipe body is sleeved with a movable shaft and a first buckle; the wheel axle of the wheel can be sleeved into the hollow pipe body; When it is stored in the hollow tube body, it is fixed with the first buckle; the opening of the hollow tube body is provided with a second buckle that is fixed with the side wall of the wheel axle when the wheel is folded.

[0032] The present invention utilizes the cooperation of the hollow pipe body, the movable shaft, the first buckle and the second buckle to realize the folding of the wheel of the balancing vehicle. During normal use, the rotating wheel shaft is parallel to the movable shaft, and the movable shaft and the wheel shaft can be embedded in the hollow body and positioned by the first buckle to prevent sliding in the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com