Automatic arraying and casing system for cupped beverages

An automatic packing and beverage technology, applied in packaging and other directions, can solve problems such as affecting packing speed and efficiency, polluting production lines, and cup body deformation, and achieves the effect of preventing material dumping, clear functions, and avoiding mutual extrusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] Further elaboration will be made below in combination with specific implementation cases.

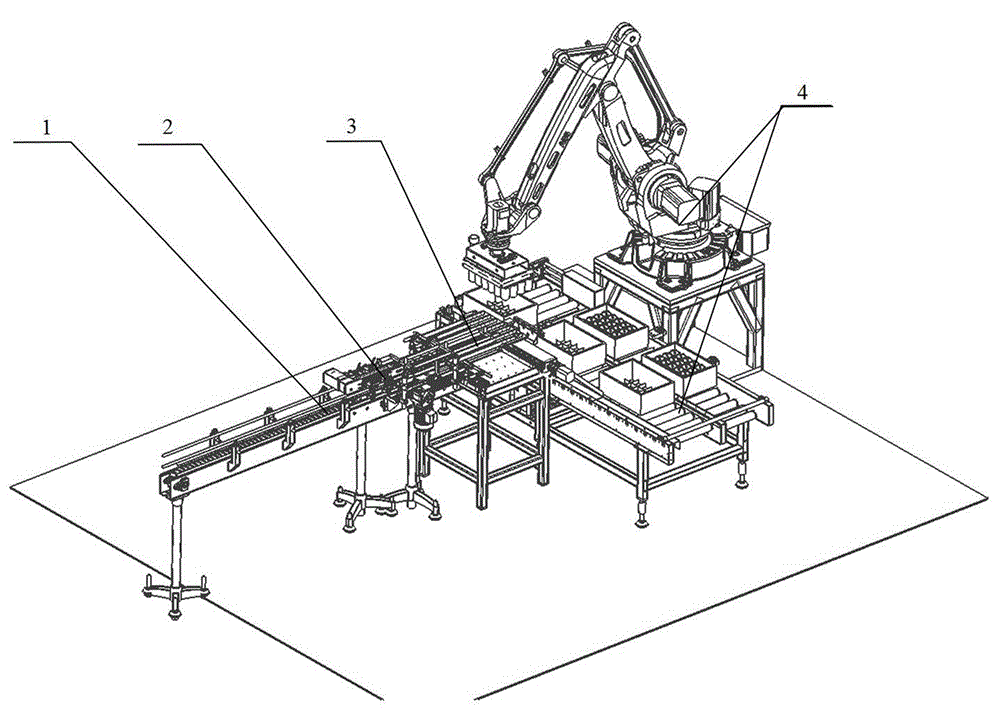

[0027] A cup-packed drink automatic boxing system provided by the invention, such as figure 1 As shown, it includes a front-end stable cup conveying mechanism 1, a one-dimensional equidistant alignment mechanism 2, a two-dimensional grouping mechanism 3 and a boxing system 4.

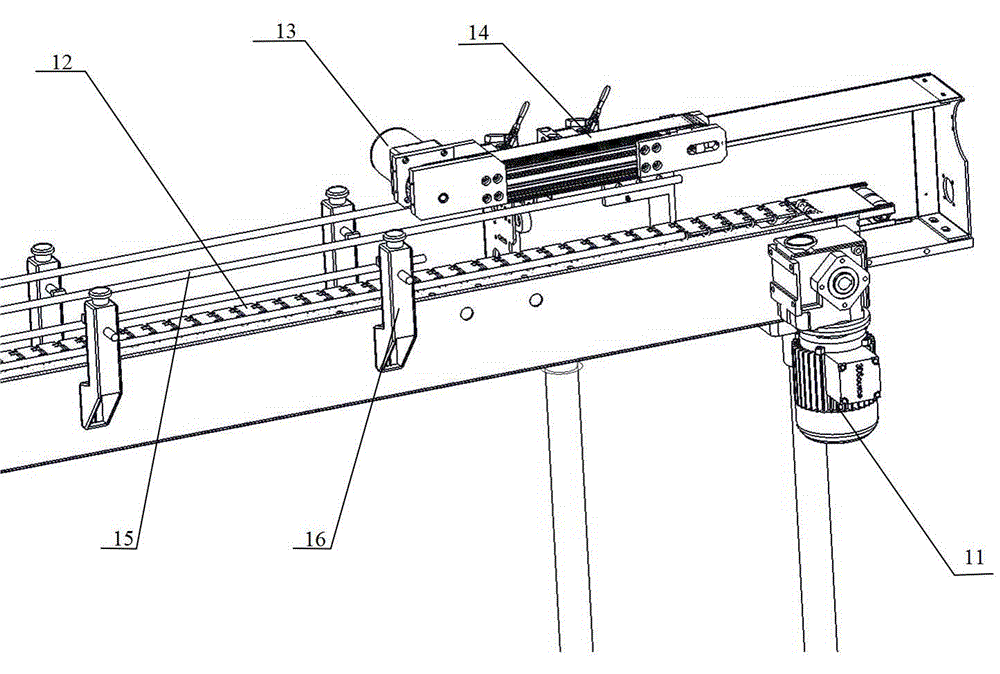

[0028] The front end stable cup conveying mechanism 1 is as figure 2 As shown, it includes a connecting conveyor belt 12 controlled by a motor 11, an upper synchronous conveyor belt 14 controlled by a motor 13, a guardrail 15 and a pressing frame 16, and the upper synchronous conveyor belt 14 is arranged in parallel on the connecting conveyor belt 12 Above the output area, the distance between the upper synchronous conveyor belt 14 and the connecting conveyor belt 12 is equal to the height of the drink in the cup, and the conveying speed and direction of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com