A kind of anti-seepage powder, anti-seepage material and its preparation and application method

A technology of anti-seepage and powder, which is applied in the fields of anti-seepage materials and anti-seepage powder, and can solve the problems of loss of anti-seepage effect and short anti-seepage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 is used to illustrate the preparation of anti-seepage material based on anti-seepage powder, which is applied to fill the gap at the bottom of the tunnel to control the water leakage from the gap at the bottom of the tunnel;

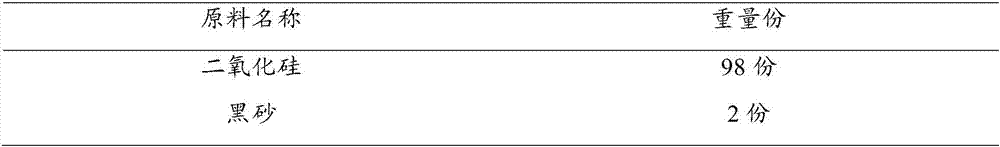

[0042] In embodiment 1, the raw material and content thereof of the anti-seepage powder for preparing anti-seepage material are as shown in the following table 1:

[0043] Table I

[0044]

[0045] In this embodiment 1, the preparation of the anti-seepage powder and the anti-seepage material and the method for filling the gap at the bottom of the tunnel may include:

[0046] The silicon dioxide and black sand are dried by natural air drying, and the dried silicon dioxide and black sand are pulverized by a pulverizer, and the silicon dioxide is passed through a 80-mesh sieve, and the black sand is passed through a 50-mesh sieve, respectively. 98 parts of silicon dioxide after sieving, 2 parts of black sand after sieving, and this 98 p...

Embodiment 2

[0049] Example 2 is used to illustrate the preparation of anti-seepage material based on anti-seepage powder, which is applied to fill the gap at the top of the tunnel to control water leakage at the top of the tunnel;

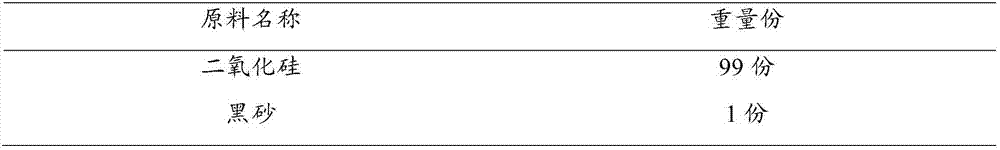

[0050] In this embodiment 2, the raw material and content thereof of the anti-seepage powder for preparing the anti-seepage material are as shown in Table II below:

[0051] Table II

[0052]

[0053] In this embodiment 2, the preparation of the anti-seepage powder and the anti-seepage material and the method for filling the gap at the top of the tunnel may include:

[0054] In the preparation process of anti-seepage powder, silicon dioxide and black sand are dried and pulverized, using the same method in Example 1, the difference is that silicon dioxide and black sand are passed through 80 mesh sieves respectively, and the 99 parts of silicon dioxide after sieving, 1 part of black sand after sieving, and this 99 parts of silicon dioxide and 1 part of blac...

Embodiment 3

[0057] Example 3 is used to illustrate the preparation of anti-seepage material based on anti-seepage powder, which is applied to laying at the bottom of the river to control water seepage at the bottom of the river;

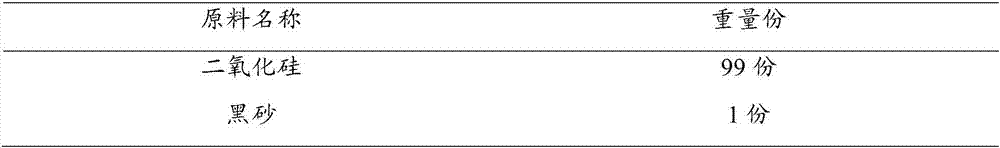

[0058] In this embodiment 3, the raw material and content thereof of the anti-seepage powder for preparing the anti-seepage material are as shown in Table III below:

[0059] Table III

[0060]

[0061] In this embodiment 3, the preparation of anti-seepage powder and anti-seepage material and the method applied to laying at the bottom of the river can include:

[0062] In the preparation process of anti-seepage powder, silicon dioxide and black sand are dried and pulverized, using the same method in Example 1, the difference is that silicon dioxide and black sand are passed through a 50-mesh sieve respectively, and the 99 parts of silicon dioxide after sieving, 1 part of black sand after sieving, and this 99 parts of silicon dioxide and 1 part of black sand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com