Precise positioning construction control method of symmetrical cantilever assembled bridge

A technology of precise positioning and control method, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of affecting the assembly accuracy of subsequent segments, difficulty in adjusting the accuracy, and easy to shake the rigidity of the boom, so as to reduce the efficiency or site The effect of influence, accurate positioning, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

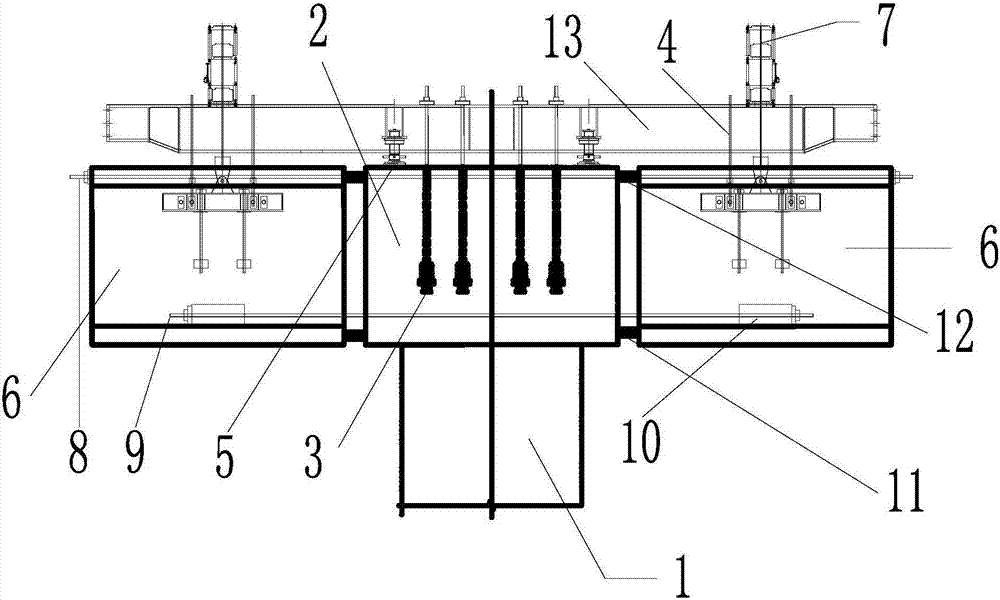

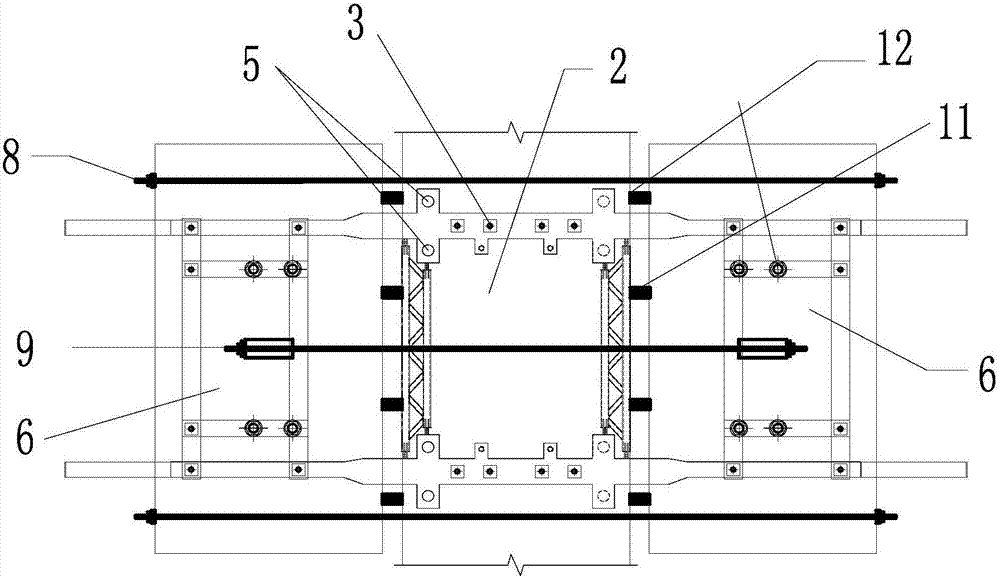

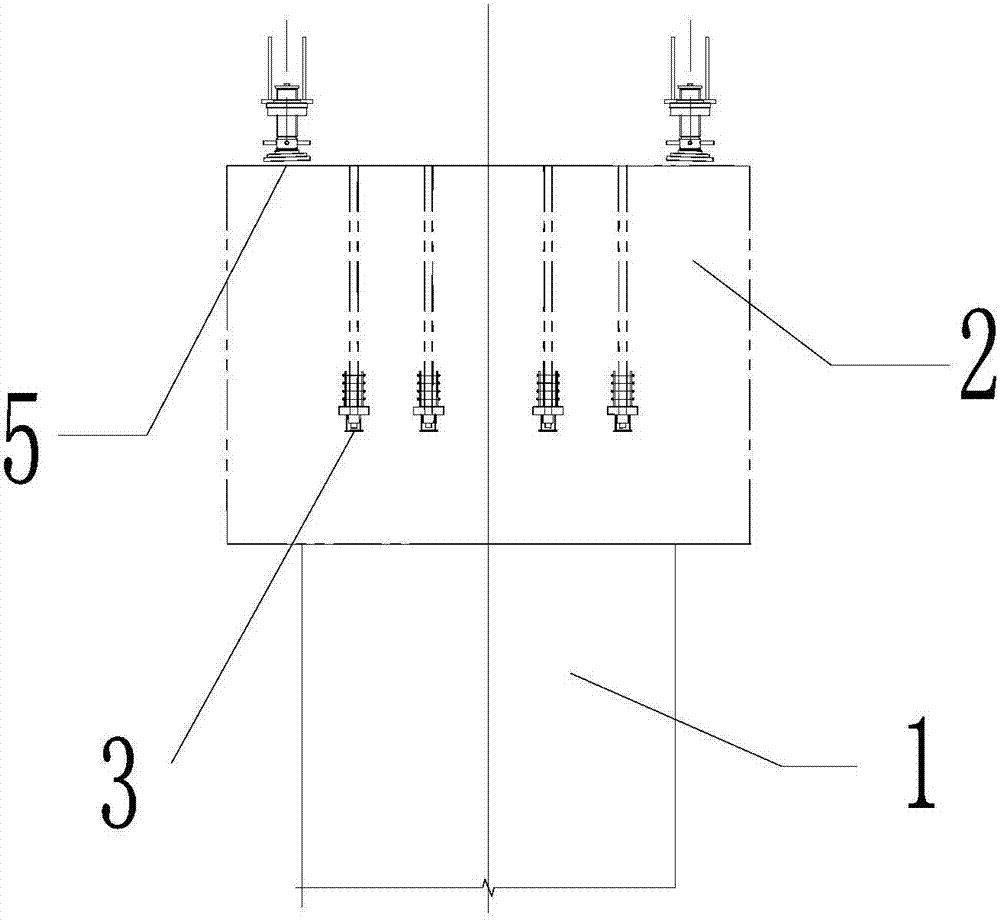

[0039] First, if image 3 , 4 Check whether the pre-embedded sleeve 3 of the cover beam is complete, use a crane to hoist the suspension system 13 to the top surface of the cover beam 2, use a 40mm diameter fine-grained screw to pass through the preset hole position of the suspension system 13, and adjust the suspension system 13 to the required Position, bear the positioning and fixation of the suspension system with screw rod and adjustable screw jack 5.

[0040] Secondly, if Figure 5 As shown, the prefabricated suspension segment 6 of the reference block is pre-installed with the devices required for hoisting, and the prefabricated suspension segment 6 of the reference block is hoisted to the end position of the suspension system 13 by a crane (or the automatic lifting device of the suspension system). The bending moment generated by the weight of the prefabricated suspension segment 6 relies on the suspension system 13 to pick out the steel beam and transmit it to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com