Connection limiter used for transition section of concrete column and concrete-filled steel tubular column

A technology for concrete-filled steel tubular columns and concrete columns, which is applied in construction, building structure and other directions, can solve problems such as difficult operation and difficult quality control, and achieve the effect of reducing the amount of measures and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The preferred specific embodiment of the connection limiter for the transition section between a concrete column and a concrete-filled steel tube column of the present invention is:

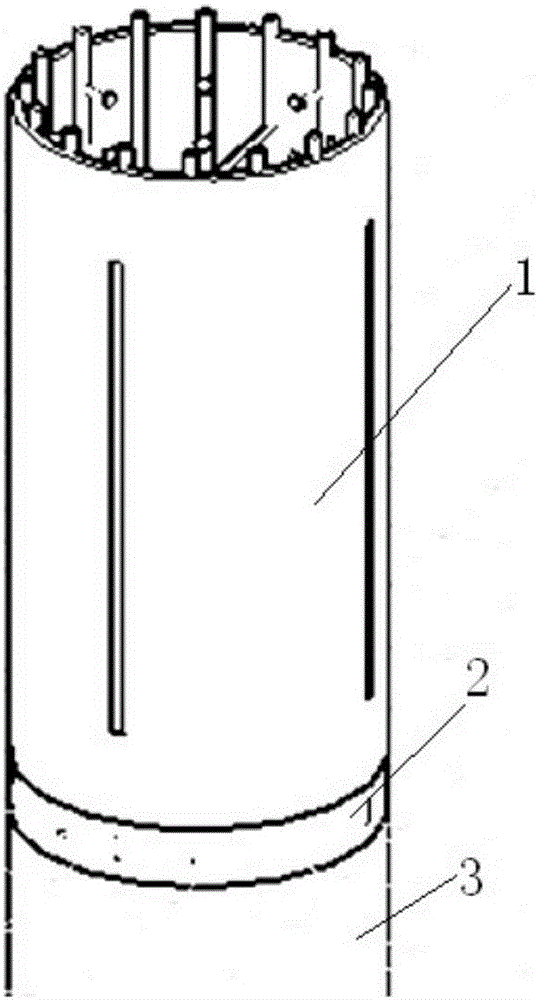

[0018] The connection limiter is arranged between the lower concrete column and the upper steel tubular concrete column, and includes a ring plate, and a rib plate and a stud are arranged in the ring plate. The thickness and direction are consistent with the position, size, thickness and direction of the ribs and studs inside the CFST column, and are used to limit the reinforcement of the concrete column.

[0019] The outer diameter of the steel bar stopper is consistent with the outer diameter of the concrete column and the steel tube concrete column.

[0020] The height of the ring plate is 50mm to 150mm, and the thickness is 8mm to 12mm.

[0021] The connection limiter used for the transition section between a concrete column and a concrete-filled steel tube column of the invention sol...

specific Embodiment

[0026] The basic composition of the connection limiter for the transition between concrete columns and concrete-filled steel tubular columns:

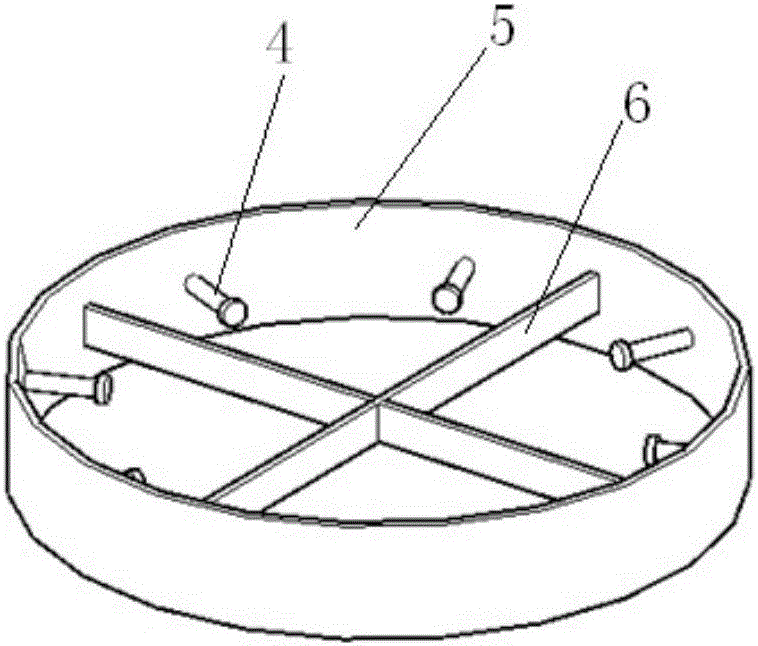

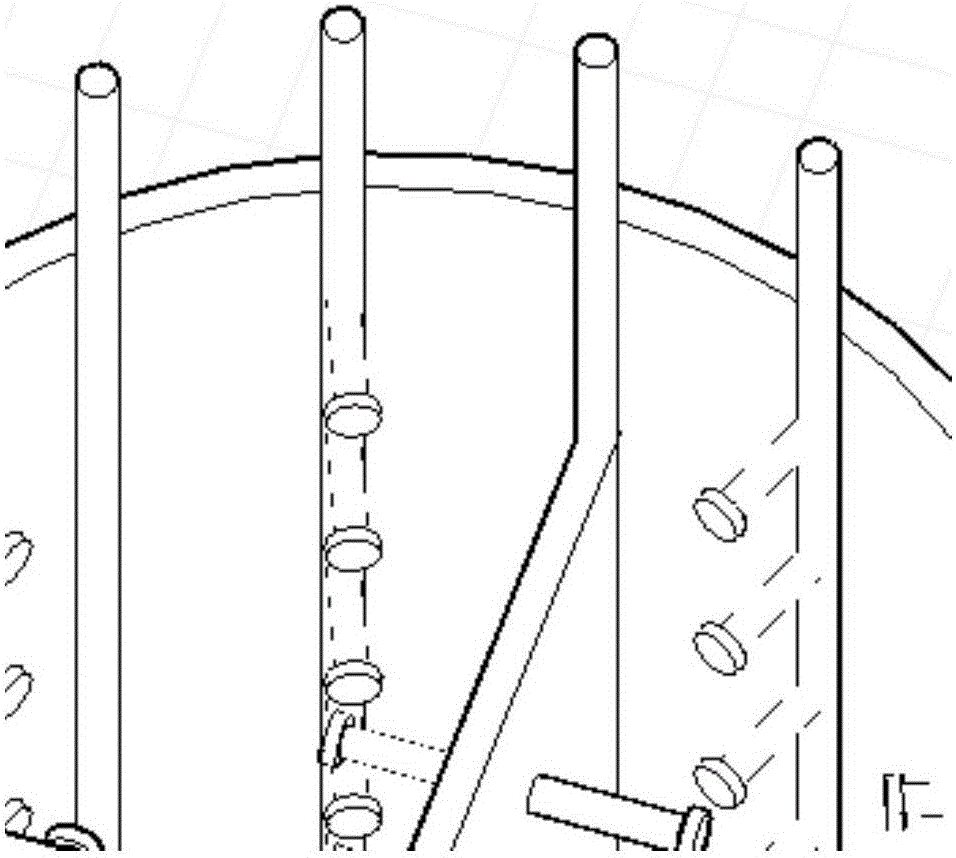

[0027] like Figure 5a , Figure 5b , Figure 5c As shown in the figure, the connection limiter used for the transition between the concrete column and the concrete-filled steel tube column is mainly composed of three parts: the ring plate, the rib plate and the stud.

[0028] 1) Design of ribs and studs:

[0029] The position, size, thickness and direction of the rib and studs should be consistent with the upper steel pipe column, so as to limit the position of the steel bar, and the height and thickness of the rib should be appropriate. .

[0030] 2) Ring plate design:

[0031] In order to avoid the situation that the concrete column formwork cannot be closed after the reinforcement stopper is installed, the outer diameter of the reinforcement stopper should be consistent with the outer diameter of the concrete column and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com