Replaceable composite steel plate energy dissipation steel structure beam-column joint

A beam-column joint and steel structure technology, applied in building components, building structures, earthquake-proof and other directions, can solve the problems of insufficient energy dissipation capacity, difficult to deform and destroy centralized replaceable components, etc. Simple, well-defined effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

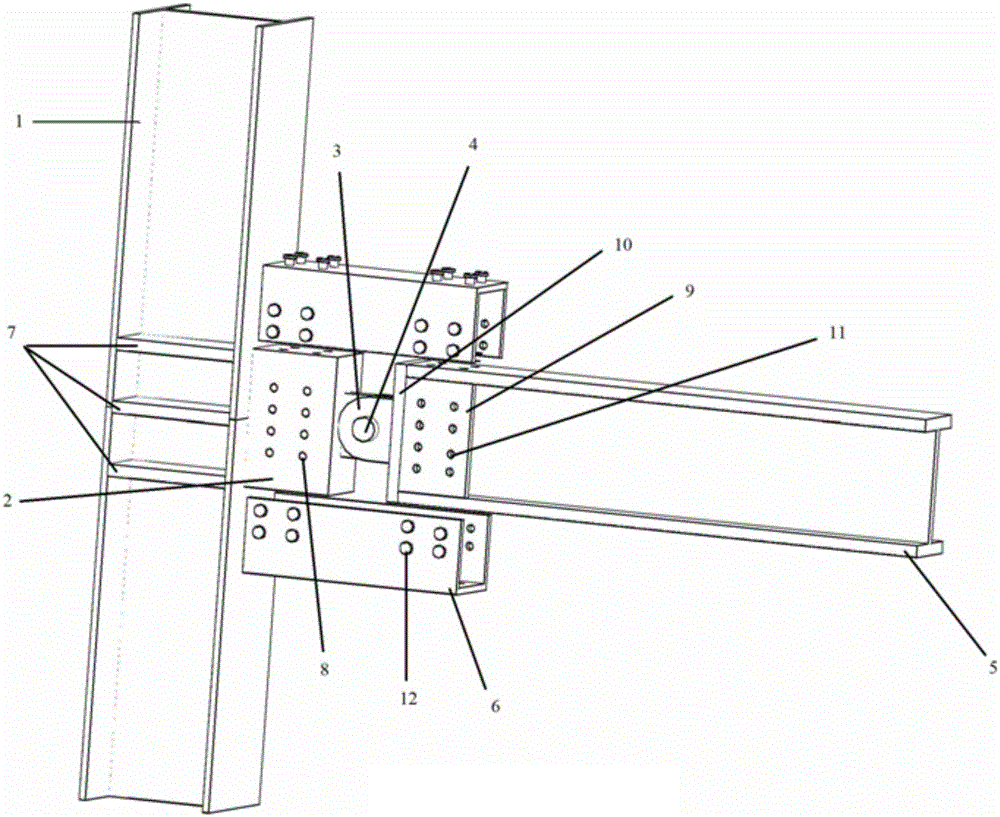

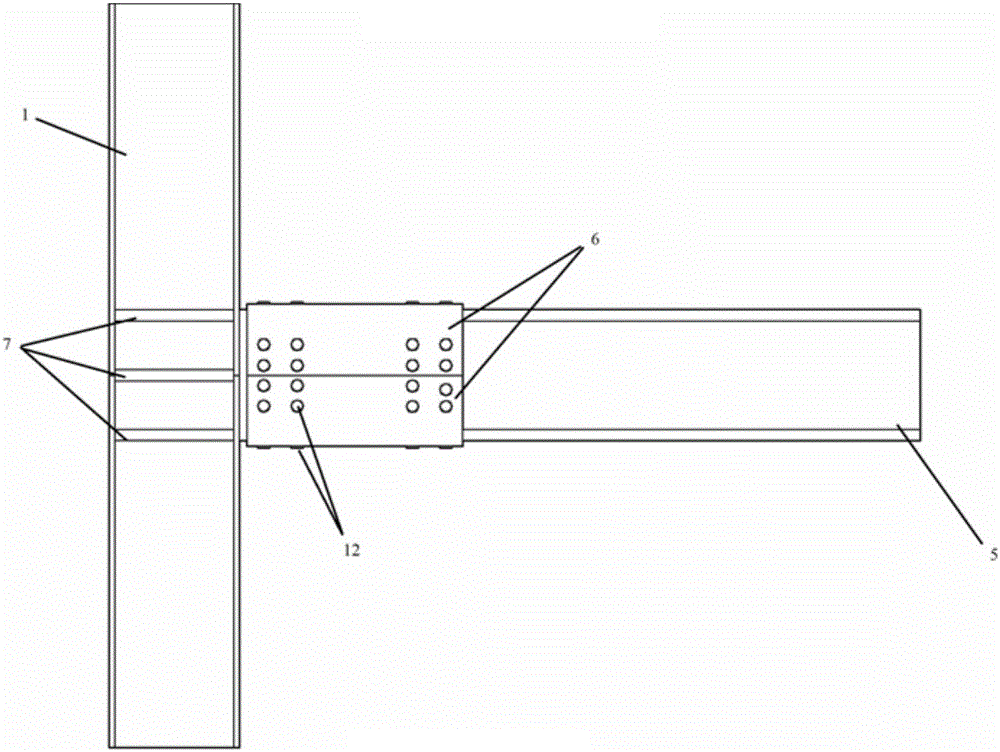

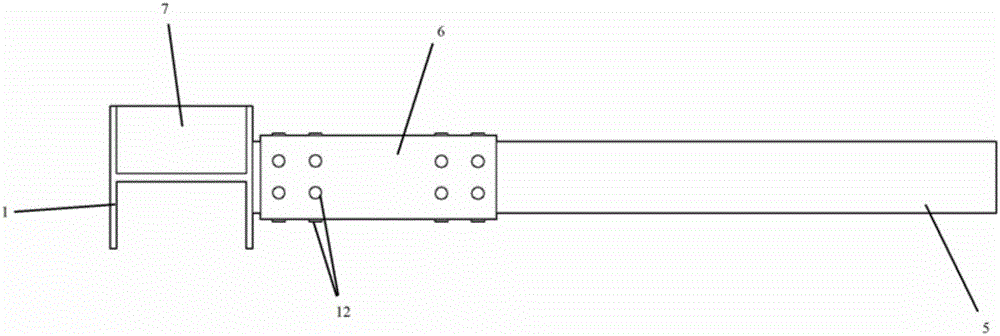

[0035] like Figure 1-13 As shown, a beam-column joint of energy-dissipating steel structure with replaceable combined steel plates includes a steel column 1, a short beam section 2 at the end of the column, an ear plate 3, a pin shaft 4, a main beam 5 and upper and lower combined steel plates 6, and a steel column 1 and one end of the short beam section 2 at the column end are connected by welding, the main beam 5 and the short beam section 2 at the column end form a hinged connection through the ear plate 3 and the pin shaft 4, and the upper and lower combined steel plates 6 are connected to the short column end section through high-strength bolts 12 The beam section 2 and the main beam 5 are fastened and connected to form a whole.

[0036] The steel column 1 independently selects the cross-section type according to the structural design requirements. In this example, H-shaped steel is selected. On the steel column 1, a plurality of horizontal stiffening ribs 7 are arranged ...

Embodiment 2

[0042] The structure of this embodiment is basically the same as that of Embodiment 1, except that the short beam section 2 at the end of the column is H-shaped steel, and is provided with a vertical side panel 9 parallel to the main beam and an end plate 10 perpendicular to the main beam. Bolt holes 11 are drilled on four faces parallel to the main beam near one end of the lug plate. The cross-sectional shape of the upper and lower combined steel plates 6 is L-shaped in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com