Hanging type multi-tower multi-span cable crane with C-shaped overhead travelling cranes and overhead travelling crane spanning method thereof

A cable crane, multi-tower connection technology, applied in cable cranes, cranes, transportation and packaging, etc., can solve problems such as passing through, and achieve the effects of simple structure, high safety, clear and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

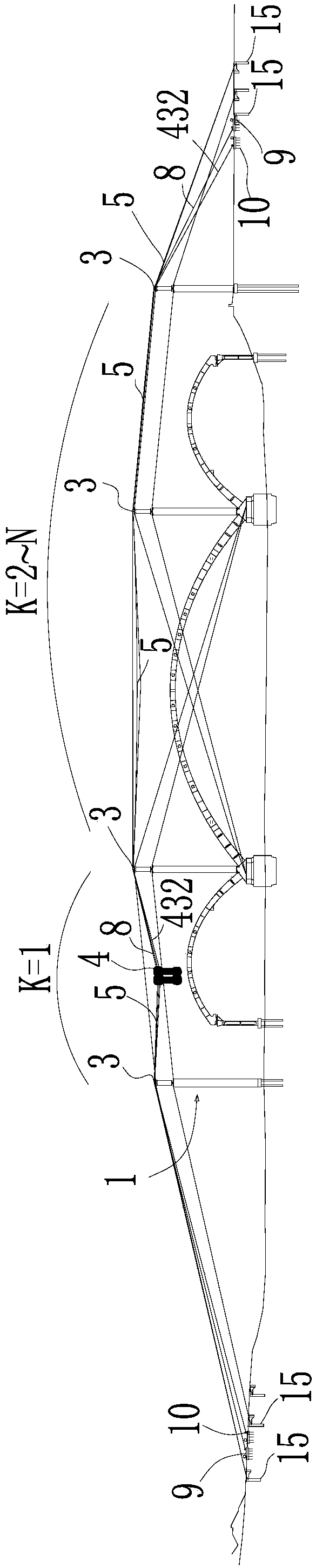

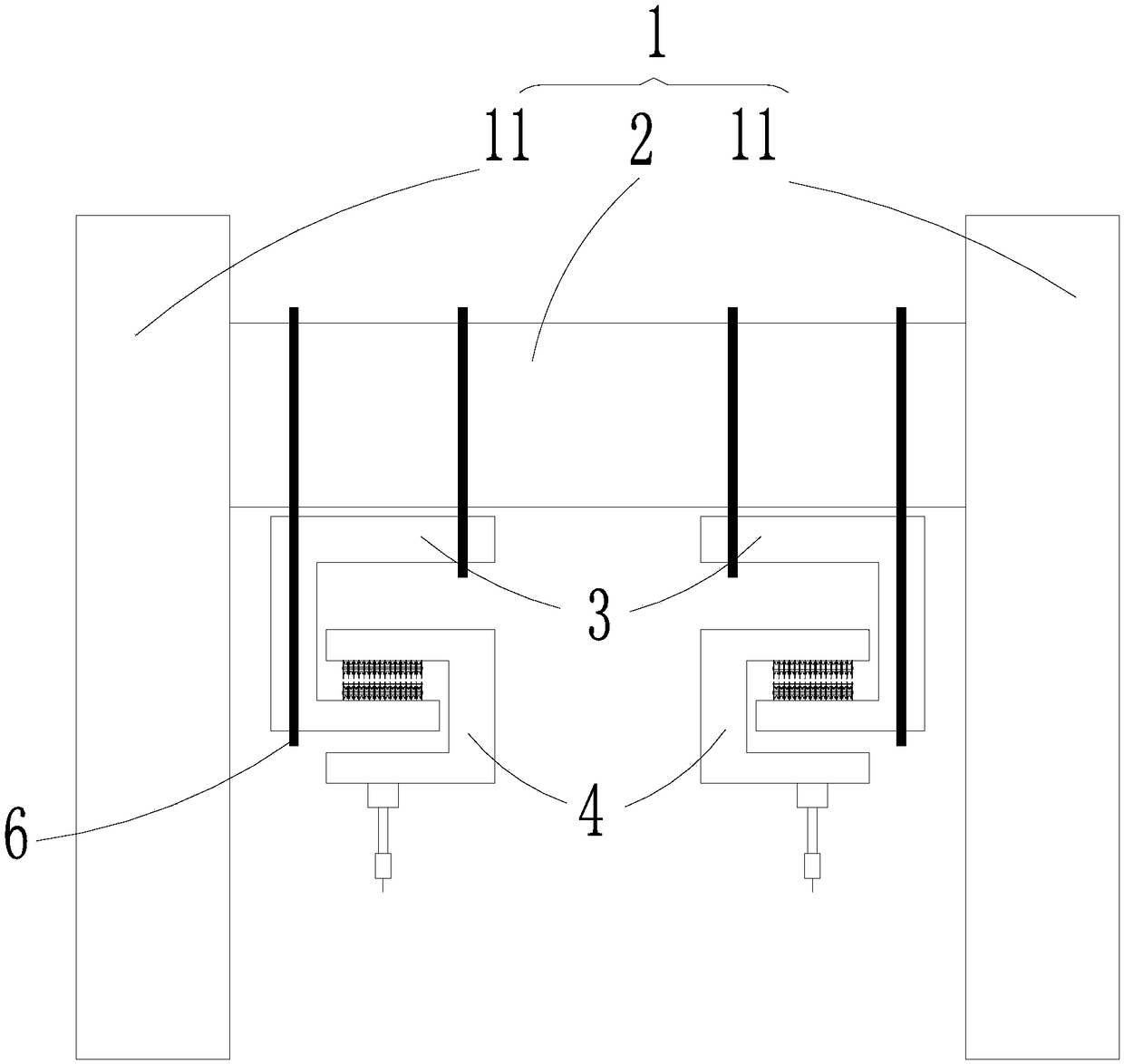

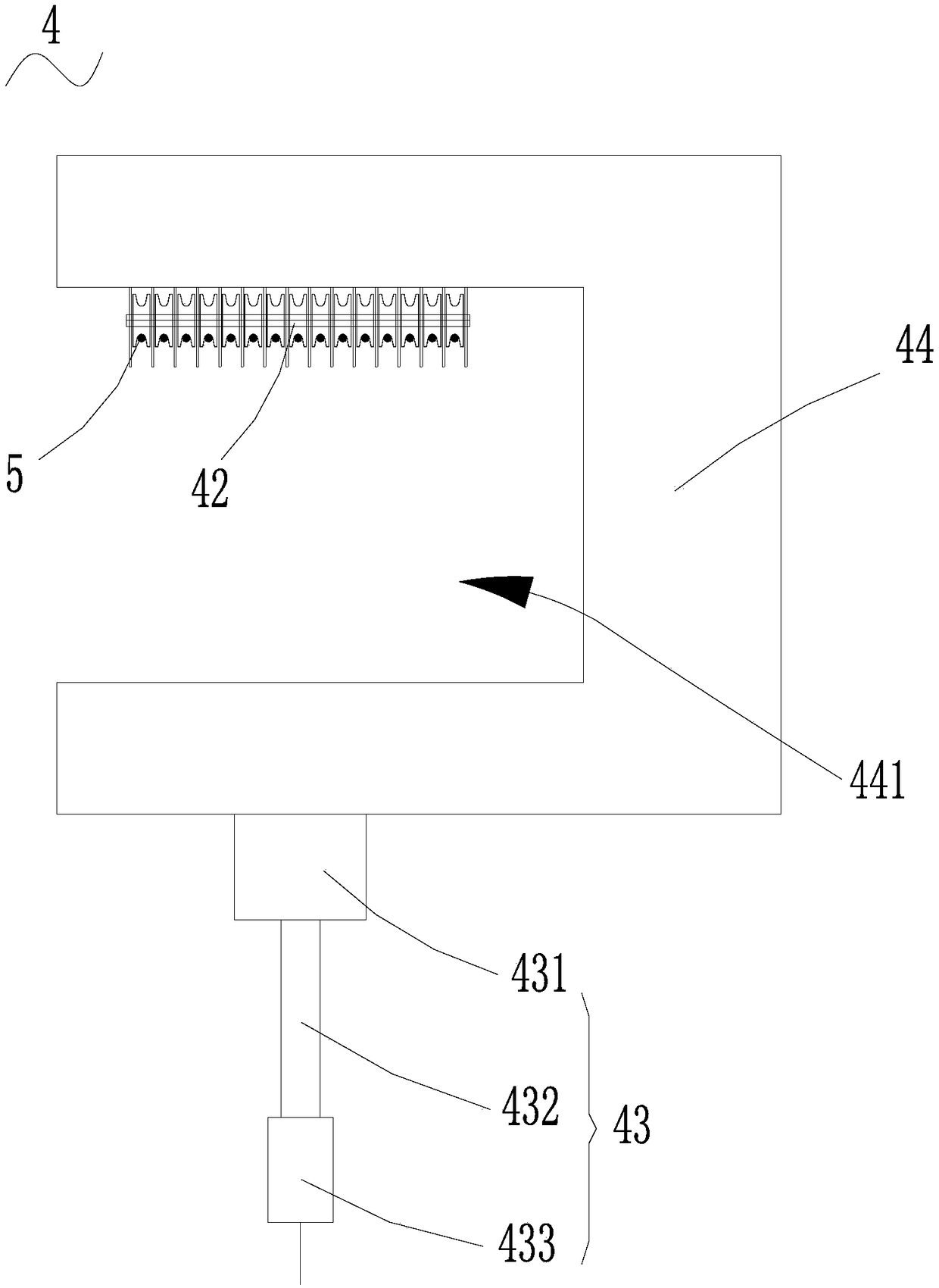

[0053] such as 1 and figure 2 As shown, the multi-tower spanning cable crane that can continuously span towers in this embodiment includes two cranes 4, two load-bearing cables 5 and a plurality of cable towers 1 arranged at intervals. Cable towers 1 include cable tower beams 2, Two vertical towers 11 and two load-bearing cable pulley shaft assemblies 32, the two vertical towers 11 are arranged at intervals along the extension direction perpendicular to the load-bearing cables 5, the cable tower beams 2 are connected between the tops of the two vertical towers 11, and the two load-bearing The cable pulley shaft assembly 32 is symmetrically arranged on both sides of the cable tower beam 2;

[0054] The two load-bearing cables 5 are correspondingly threaded and wound in the two load-bearing cable wheel shaft assemblies 32 of the plurality of cable towers 1 , and a hoisting span is formed between two adjacent cable towers 1 .

[0055] The four-tower three-span suspension cable ...

Embodiment 2

[0070] Such as figure 1 and Figure 5 As shown, the multi-tower spanning cable crane that can continuously span towers in this embodiment includes two cranes 4, two load-bearing cables 5 and a plurality of cable towers 1 arranged at intervals. Cable towers 1 include cable tower beams 2, Two vertical towers 11 and two load-bearing cable pulley shaft assemblies 32, the two vertical towers 11 are arranged at intervals along the extension direction perpendicular to the load-bearing cables 5, the cable tower beams 2 are connected between the tops of the two vertical towers 11, and the two load-bearing The cable pulley shaft assembly 32 is symmetrically arranged on both sides of the cable tower beam 2.

[0071] The two load-bearing cables 5 are correspondingly threaded and wound in the two load-bearing cable wheel shaft assemblies 32 of the plurality of cable towers 1 , and a hoisting span is formed between two adjacent cable towers 1 .

[0072] The four-tower three-span suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com