Material rake mechanism arranged on spiral material picking machine and used for loosening materials

A technology of reclaimer and material rake, which is applied in the direction of transportation, packaging, loading/unloading, etc., and can solve problems such as difficult installation, large welding volume, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

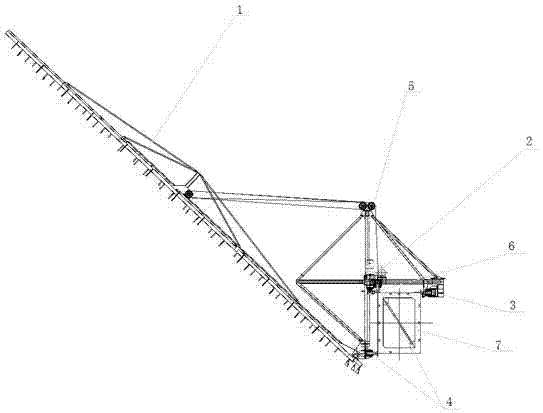

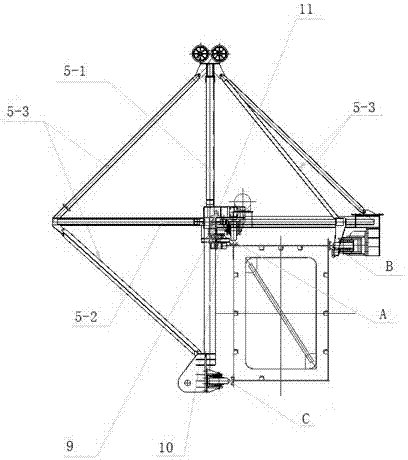

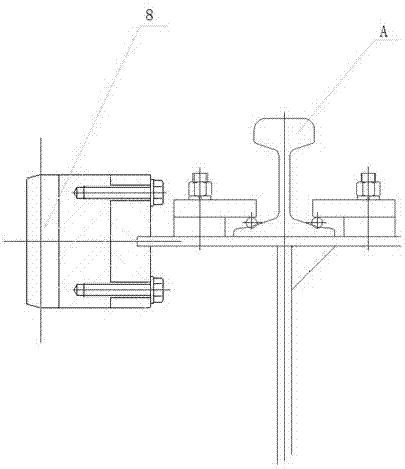

[0013] Referring to the accompanying drawings, a rake mechanism for loose materials on a screw reclaimer includes a rake 1, a winch mechanism 2, a four-wheel assembly 3, a two-wheel assembly 4, a rake bracket 5, and a rack and pinion drive Device 6, box girder 7, rack 8, driving device 9, driving gear 10, motor 11, the rake 1 is hinged with the rake bracket 5 at the bottom beam, and the upper part of the rake 1 is fixed on the rake bracket 5 The hoisting mechanism 2 above is used to adjust the pitch angle, and the rake support 5 adopts a statically definite truss structure. The four-wheel assembly 3 and the two-wheel assembly 4 fixed on the rake support 5 are driven by the rack-and-pinion transmission device 6. Drive the material rake 1 to reciprocate to complete the work of loosening the material; the transmission device of the material rake mechanism is a rack and pinion transmission device 6, the rack 8 is fixed on the side of the box beam 7, and the driving device 9 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com