A cable support structure and installation method of a shaft-hinged cable crane

A cable crane and cable support technology, which is applied to cable cranes, cranes, traveling mechanisms, etc., can solve the problems affecting the safety of cable crane equipment, the easy overturning of the cable support, and the easy overturning of the trolley, so as to achieve light weight and stress Clear and reasonable, avoid the effect of mutual friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

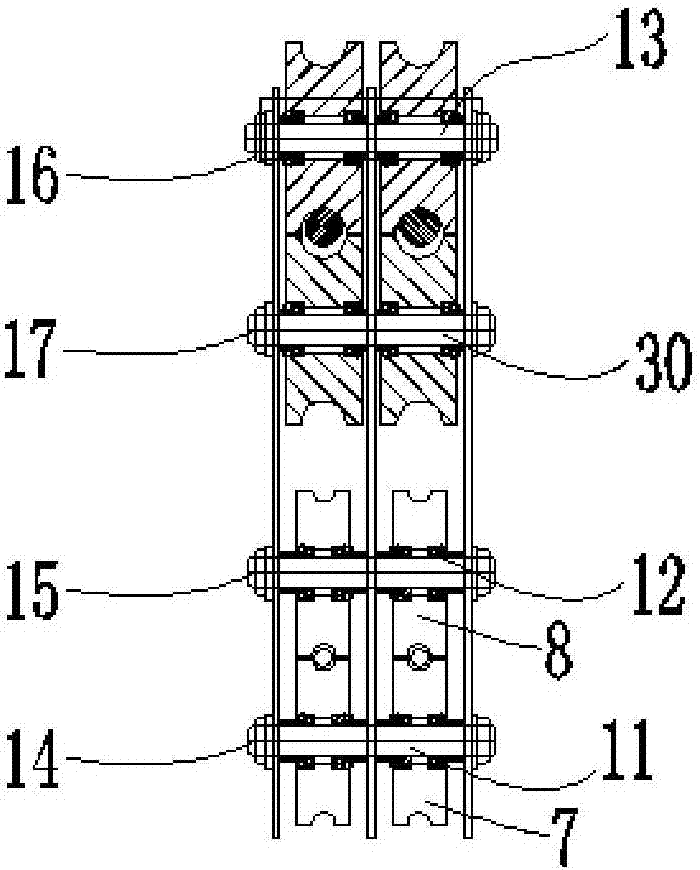

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "front", "rear", "left" and "right" appear in the following, it only means that they are consistent with the front, rear, left and right directions of the drawings themselves, and do not limit the structure.

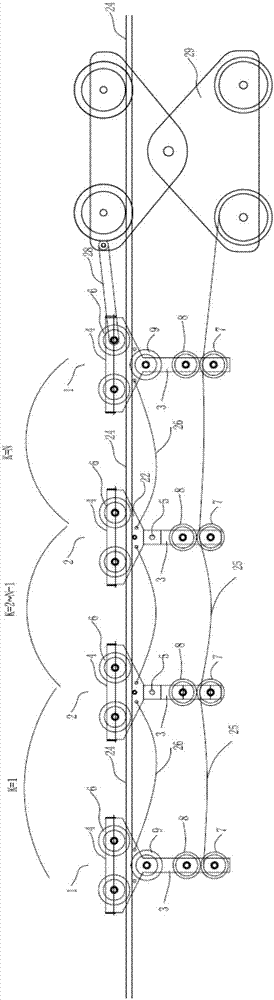

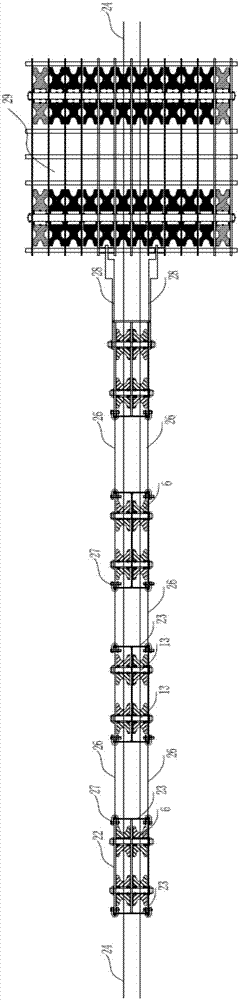

[0034] A shaft-hinged cable crane support structure, such as Figure 1-4 As shown, the first support device 1, the second support device 2, the support bracket 3, the trolley 4, the hanger shaft 5, the trolley wheel 6, the hoisting wheel 7, the hoisting wheel 8, the bearing Soto wheel 9, load-bearing soto shaft 10, first pin 11, second pin 12, third pin 13, first anti-off nut 14, second anti-off nut 15, third anti-off nut 16, The fourth anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com