Installing process of aluminum formwork

An installation process and aluminum formwork technology, applied in the field of building pouring, can solve problems such as layout arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

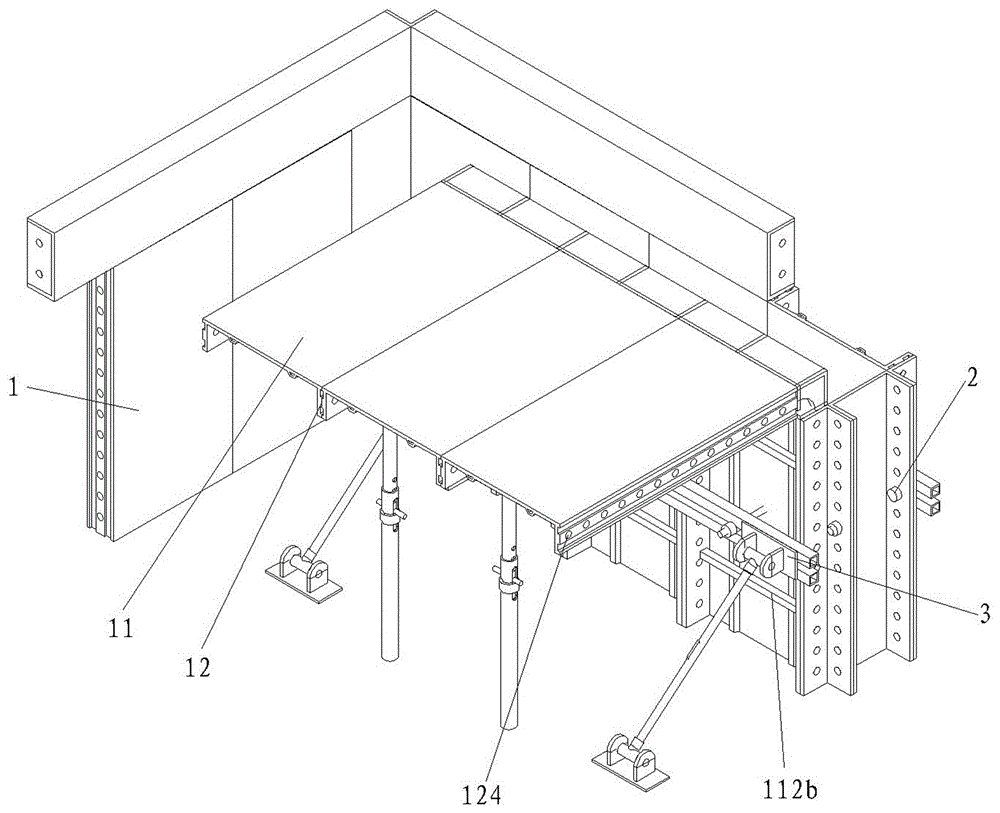

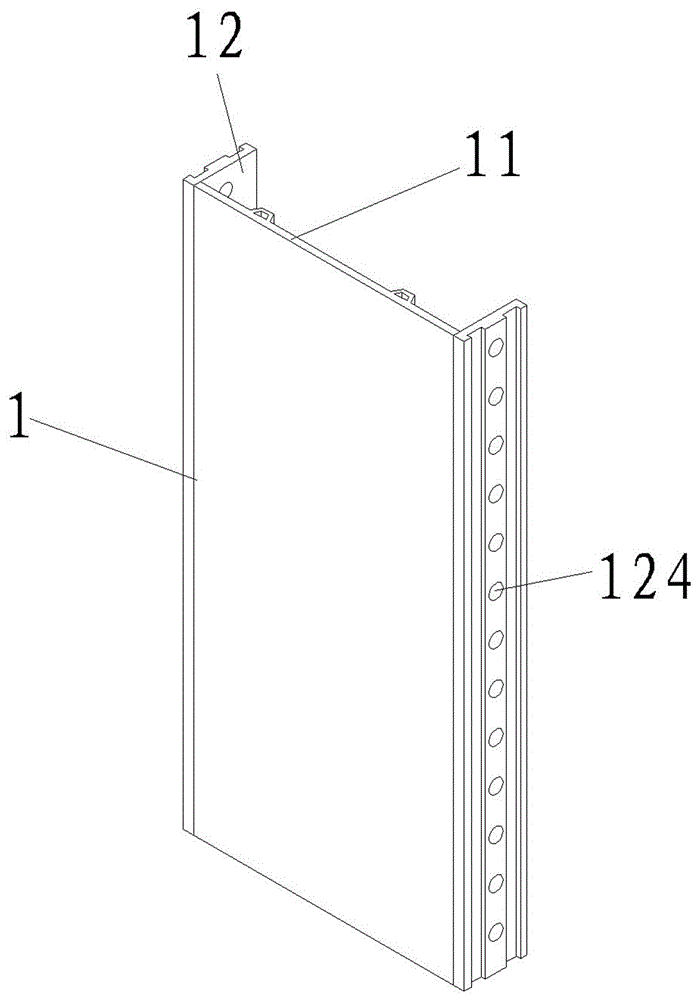

[0031] shaped like figure 1 The structure shown needs to be as figure 2 The various structures shown are realized through the following steps.

[0032] Implementation column 1, an installation process of aluminum formwork, is characterized in that, comprises the following steps:

[0033] A. On the first day, first of all, measure the perimeter of the aluminum formwork unit 1 that needs to be placed on the construction site, and mark it;

[0034] Then, the wall column formwork is preset, and the steel bars are installed in the wall column formwork; the reinforcement installation includes the installation of the positioning bars and the removal of the caisson formwork.

[0035] Finally, remove the preset wall column formwork and transfer it to the upper layer, and then apply a release agent on the preset surface;

[0036] B. On the second day, first, insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com