Submarine cable laying protection device and installation method at the foundation of offshore wind power jacket

A technology for offshore wind power and submarine cable laying, which is applied in cable installation and ground cable installation, etc., to achieve the effects of simplifying the construction process, shortening the construction period, and optimizing the laying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

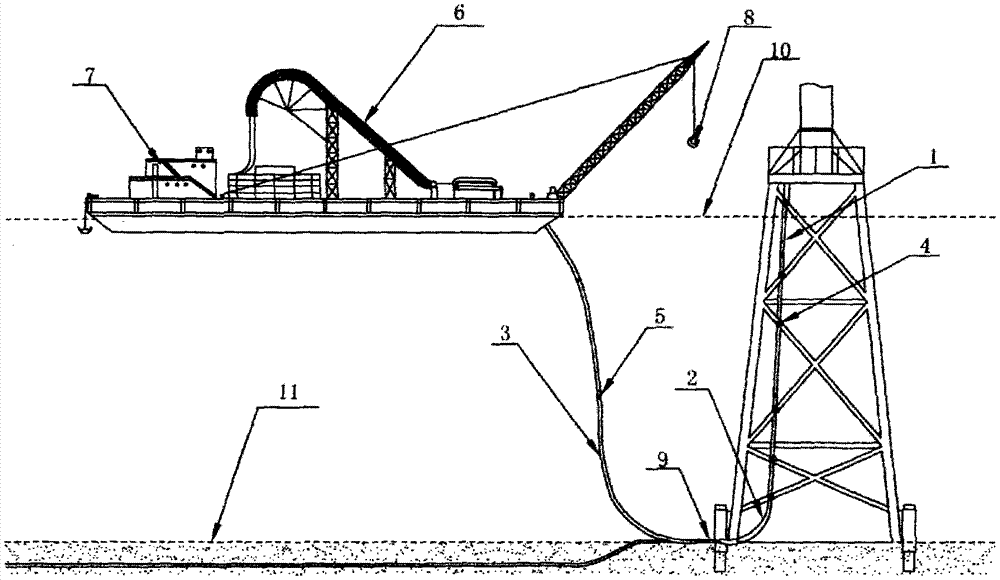

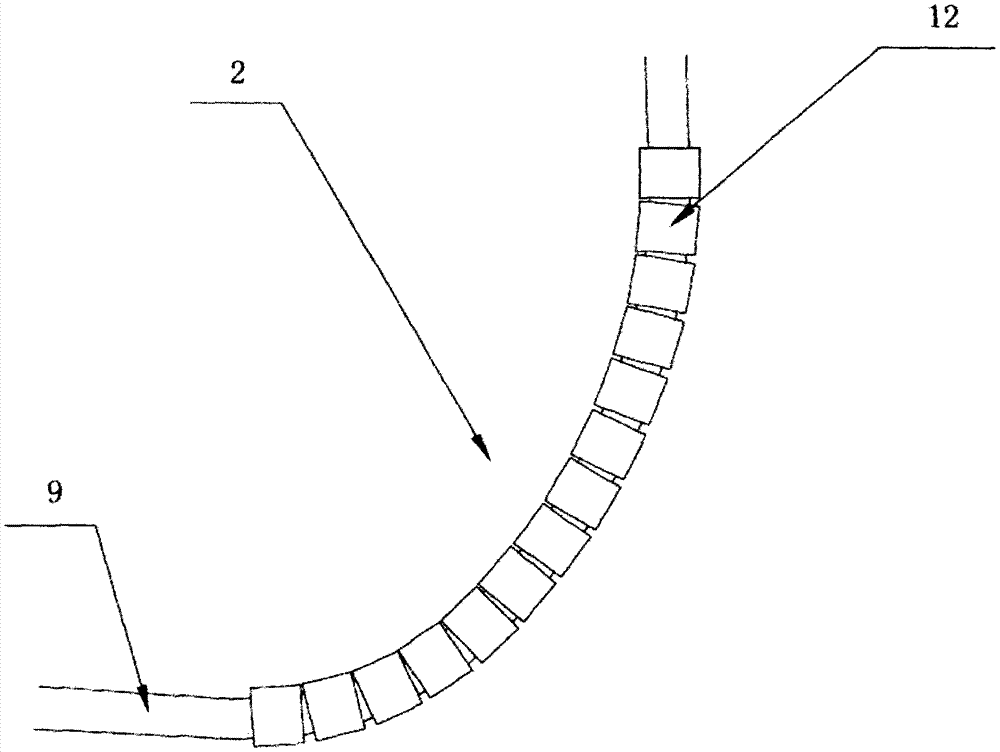

[0021] The submarine cable laying protection device and installation method at the foundation of the offshore wind power jacket, including the first protective sleeve 1, the second protective sleeve 2 and the third protective sleeve 3; the first protective sleeve 1 and the second protective sleeve 2. Fix it on the wind turbine jacket foundation through the fixed connection device 4 in advance, put the third protective sleeve 3 on the submarine cable 9 to be laid on the shore, and reserve a space slightly larger than the first protective sleeve at the terminal of the submarine cable. The unprotected section of the total length of the pipe 1 and the second protective casing 2; after the installation of the third protective casing 3 is completed, the submarine cable 9 covered with the third protective casing 3 is shipped by the construction ship 7 to the wharf, and the cable is used for traction When the construction ship 7 arrives near the wind turbine terminal, put the torsion f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com