A method for laying a fusion-free double-layer sea pipe monitoring optical cable

A laying method and sea pipe technology, applied in the direction of optical fiber/cable installation, optics, light guide, etc., can solve problems such as low strength of optical cables, slow down construction progress, and failure of monitoring systems, so as to optimize the laying process and avoid performance degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

[0026] As shown in the figure, this embodiment provides a method for laying a fusion-free double-layer sea pipe monitoring optical cable, including the following steps:

[0027] Step (1): laying the horizontal section of the sea pipe.

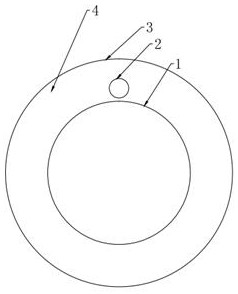

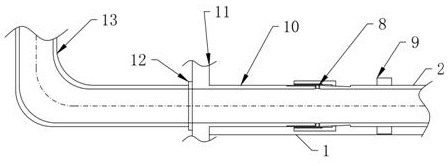

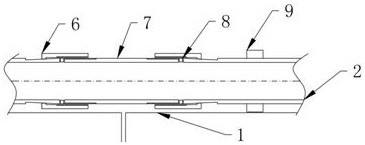

[0028] The horizontal section of the sea pipe includes an inner pipe 1 for transporting oil and gas, an outer pipe 3 in which the inner pipe 1 is sheathed, and a protection device for protecting optical cables arranged between the inner and outer pipes 1 and 3 . Sleeve 2, the two ends of the protection sleeve 2 are respectively connected with a protection hose 13, the protection hose 13 is located outside the outer tube 3; the outer tube 3, the inner tube 1, the protection sleeve 2 It is respectively spliced by multiple sections of outer short pipes, inner short pipes, and protective short pipes; the annular sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com