Engine

A technology for engines and permanent magnet generators, applied in the direction of engine ignition, engine components, engine lubrication, etc., can solve problems such as weight, cost increase, structure complexity, and maintenance cycle shortening, so as to improve reliability and rigidity , the effect of preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] Hereinafter, examples of an engine to which the present invention is applied will be described.

[0063] The engine of the embodiment is laterally mounted on, for example, a four-wheeled off-road vehicle ATV as a driving power source.

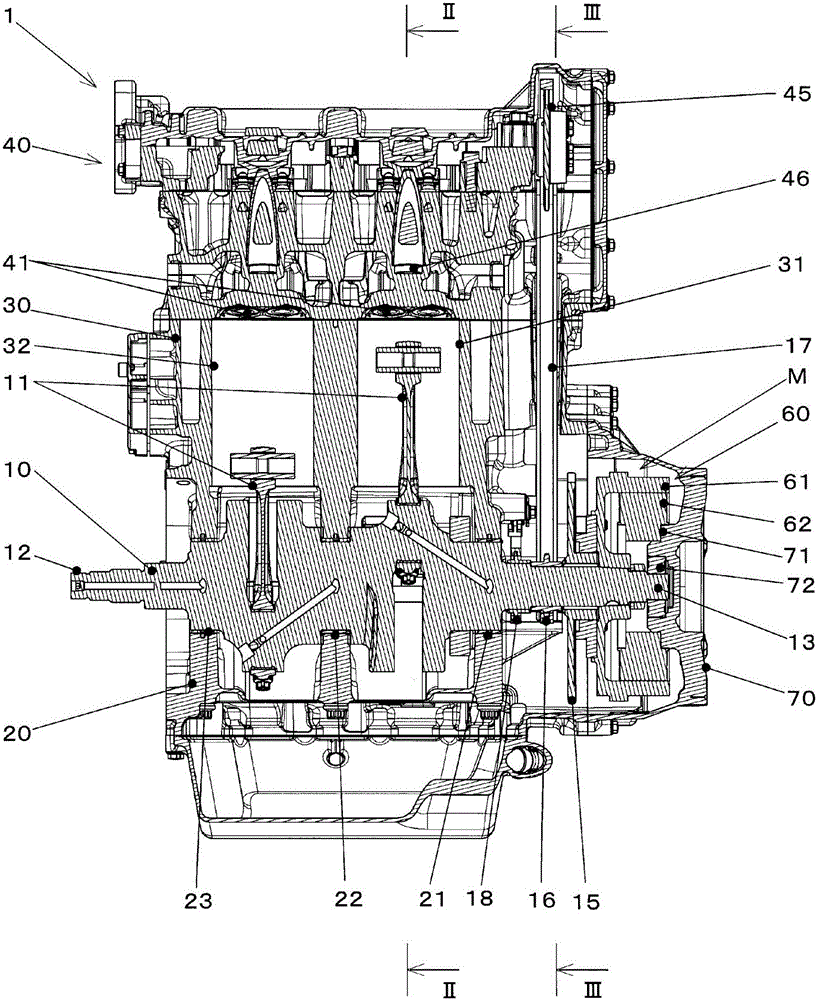

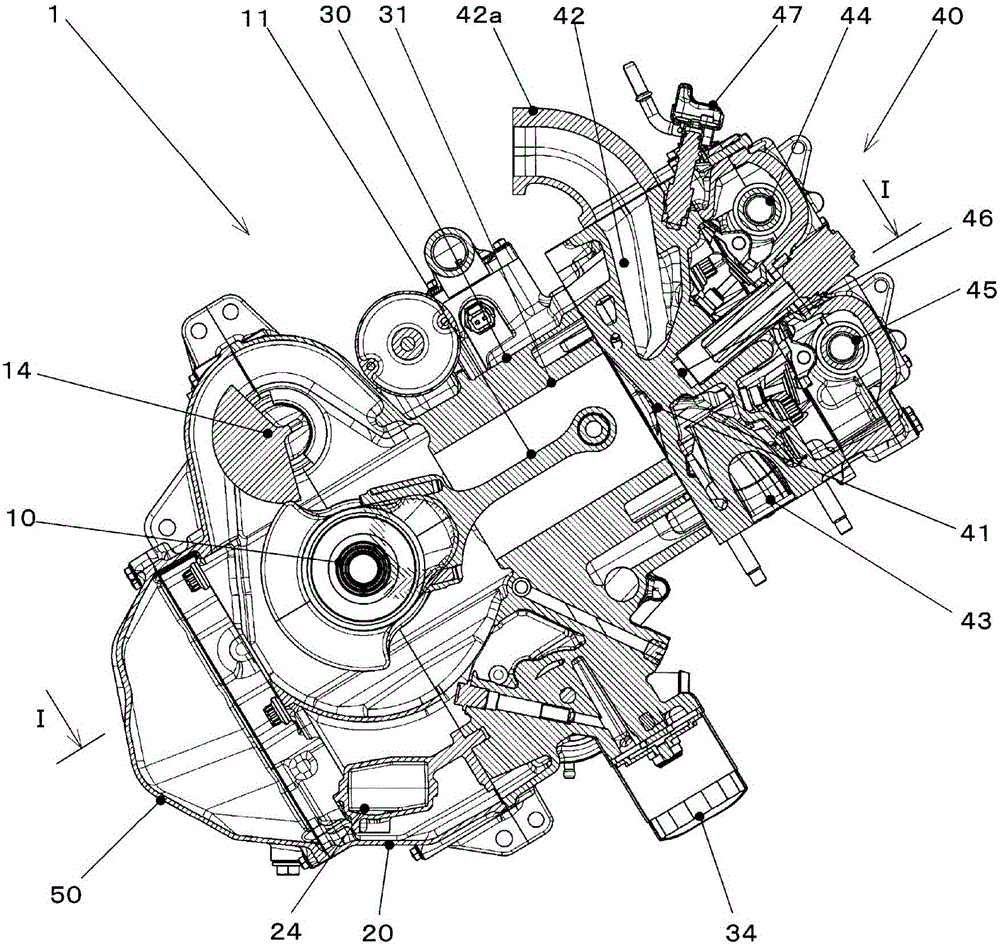

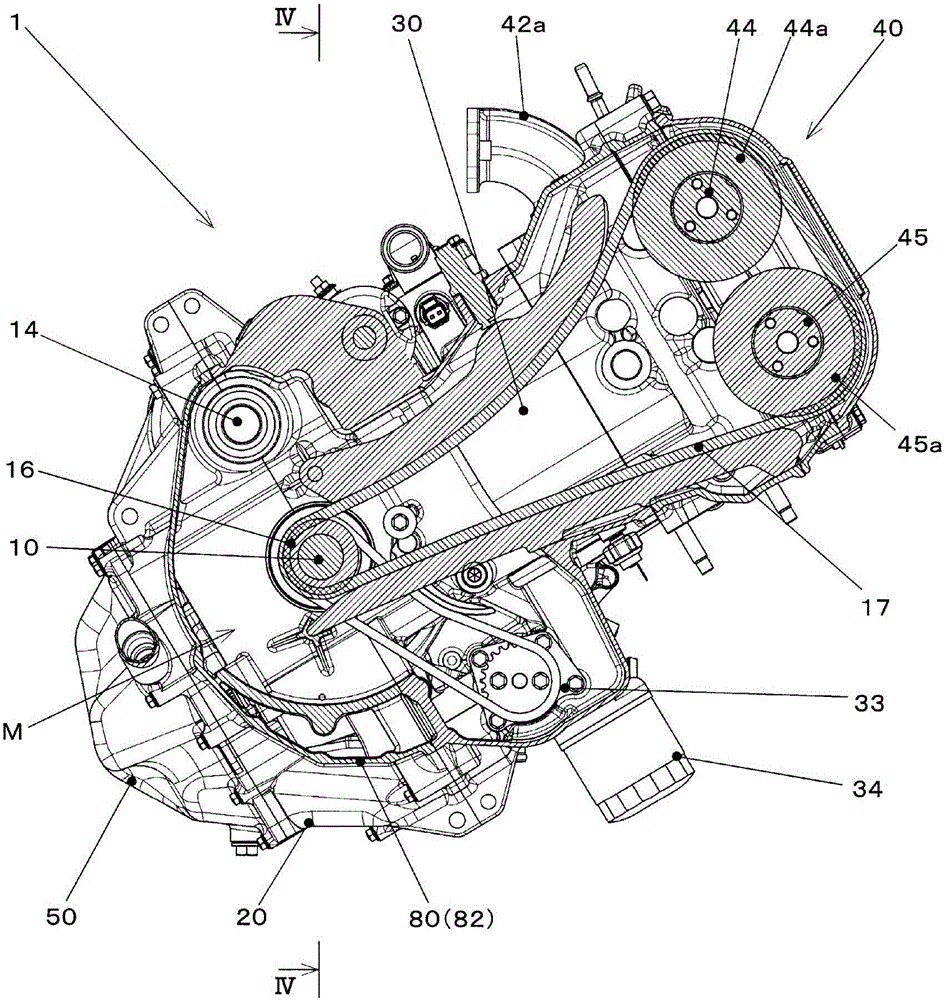

[0064] The engine of the embodiment is a four-stroke water-cooled parallel two-cylinder four-valve DOHC gasoline engine.

[0065] figure 1 The cross-sectional view of the engine of the embodiment is a view cut and viewed on a plane including the crankshaft axis and the cylinder axis ( figure 2 Sectional view of I-I section).

[0066] figure 2 yes figure 1 Sectional view of Part II-II.

[0067] image 3 yes figure 1 Sectional view of Part III-III.

[0068] Figure 4 yes image 3 Sectional view of part IV-IV.

[0069]The engine 1 includes a crankshaft 10 , a crankcase 20 , a cylinder block 30 , a cylinder head 40 , an oil pan 50 , a permanent magnet generator 60 , a permanent magnet generator cover 70 , a sub oil pan 80 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com