Refrigerating mechanism used for cooling of interior of vehicle headlamp assembly

A technology for automobile headlights and headlights, which is applied to vehicle parts, cooling/heating devices of lighting devices, road vehicles, etc. needs, the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

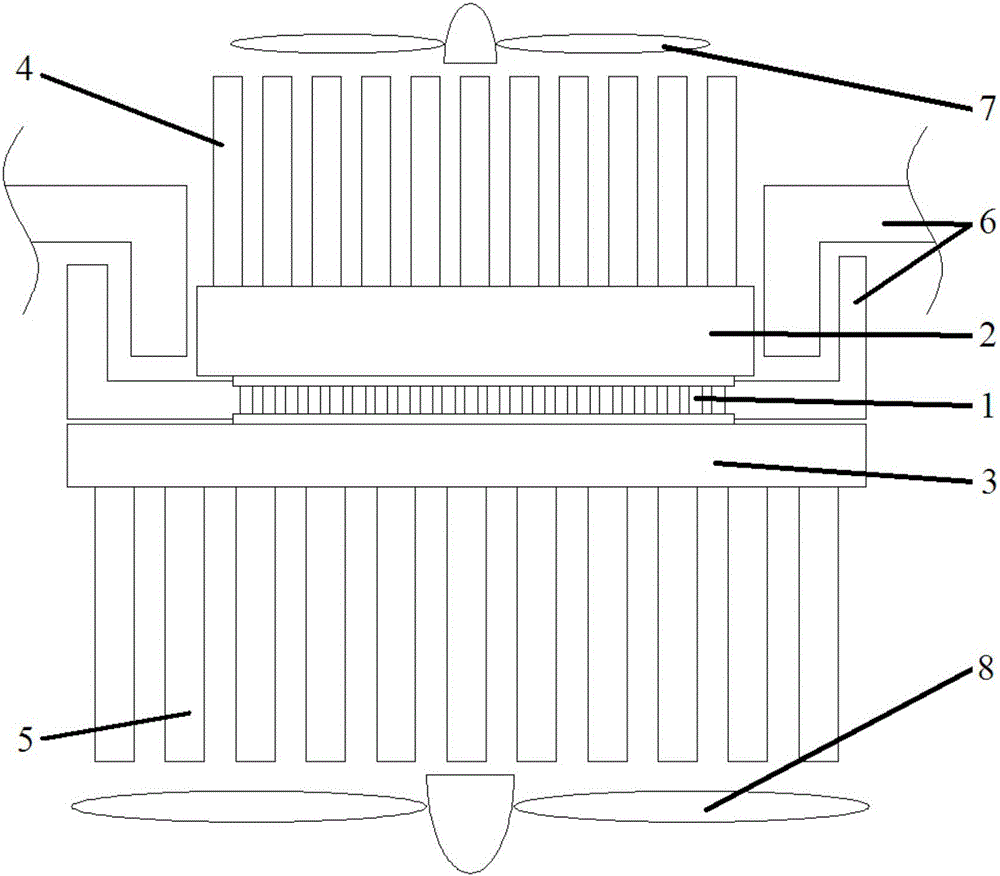

[0011] see figure 1 , a refrigeration mechanism used for cooling the interior of the vehicle headlight assembly, including a semiconductor refrigeration sheet 1 installed on the casing of the automobile headlight assembly or the inspection hole cover, the cold surface of the semiconductor refrigeration sheet 1 faces the car The inside of the headlight assembly is also connected with cooling fins 2, and the hot surface of the semiconductor cooling sheet 1 faces the outside of the automobile headlight assembly and is connected with cooling fins 3, and the cooling fins 2 and cooling fins 3 are respectively connected with Cooling fins 4 and cooling fins 5.

[0012] In the present invention, the semiconductor cooling chip 1 is fixed on the shell of the automobile headlight assembly or the cover plate of the inspection hole through the connecting mechanism 6 .

[0013] A circulating fan 7 and a cooling fan 8 are installed on the outer sides of the cooling fins 4 and the cooling fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com