LED automobile high beam

A technology of high beam and lamps, which is applied in the field of LED car headlight high beam lamps to reduce the glare of lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

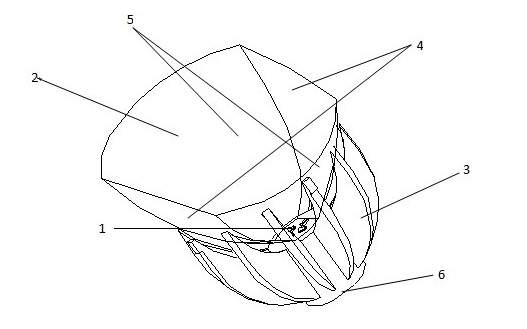

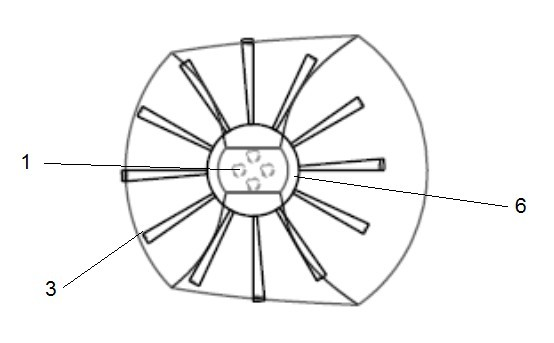

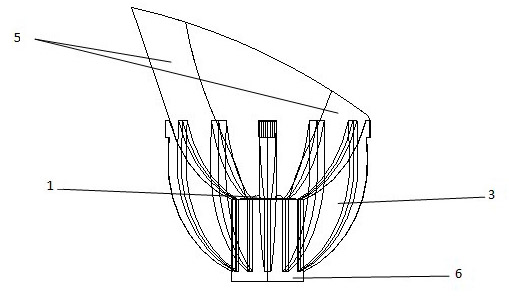

[0018] As shown in the figure for the LED car high beam lamp structure, the reflector 2 includes a first parabola 4, a second parabola 5, a third parabola 4, and a fourth parabola 5 that are connected in sequence; the first parabola 4 also Connected to the fourth parabolic surface 5; the first parabolic surface 4 and the third parabolic surface 4 are completely symmetrical, the second parabolic surface 5 and the fourth parabolic surface 5 are constrained by the same parabolic surface equation, and the area of the fourth parabolic surface 5 is larger than the first The area of the two parabolic surfaces 5; the focal points of all parabolic surfaces coincide. The LED light-emitting source group 1 is set at the focal point, and the LED light-emitting source group is fixed on the LED mounting base 6, and the outside of the LED mounting base 6 is provided with a claw-shaped heat dissipation shell 3. According to the requirements of the shape of the light spot, the distance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com