Test device and detection method for detecting comprehensive performance degradation of rolling linear guideway pair

A linear guide pair, comprehensive performance technology, applied in the direction of measuring devices, testing wear resistance, testing of mechanical parts, etc., can solve the problem of prolonging the loss of accuracy and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

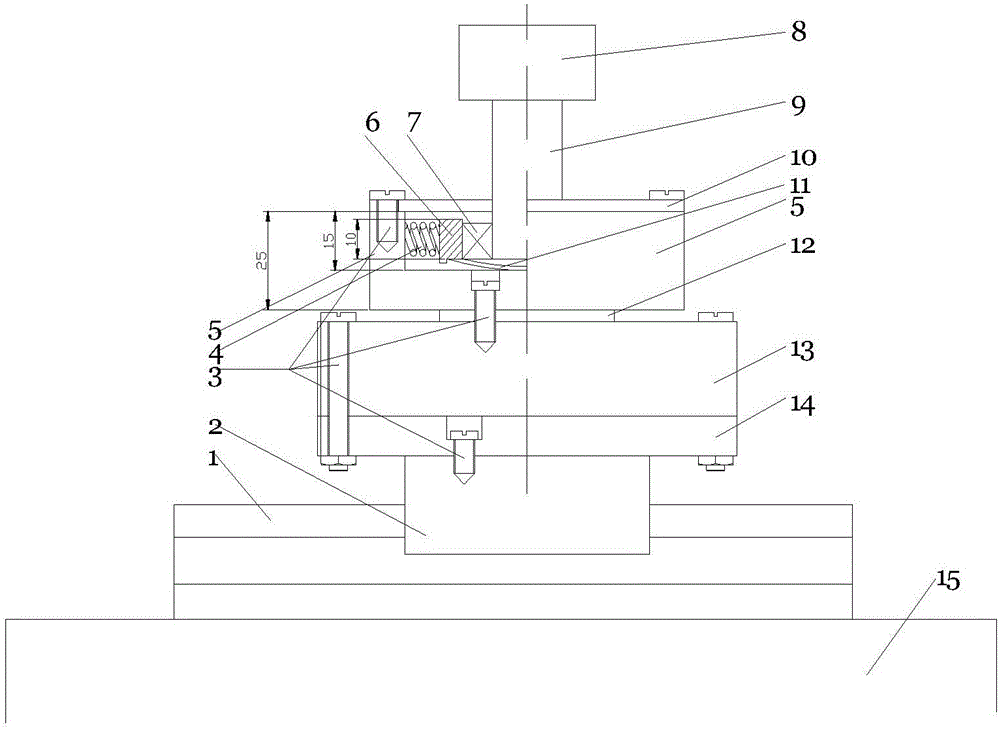

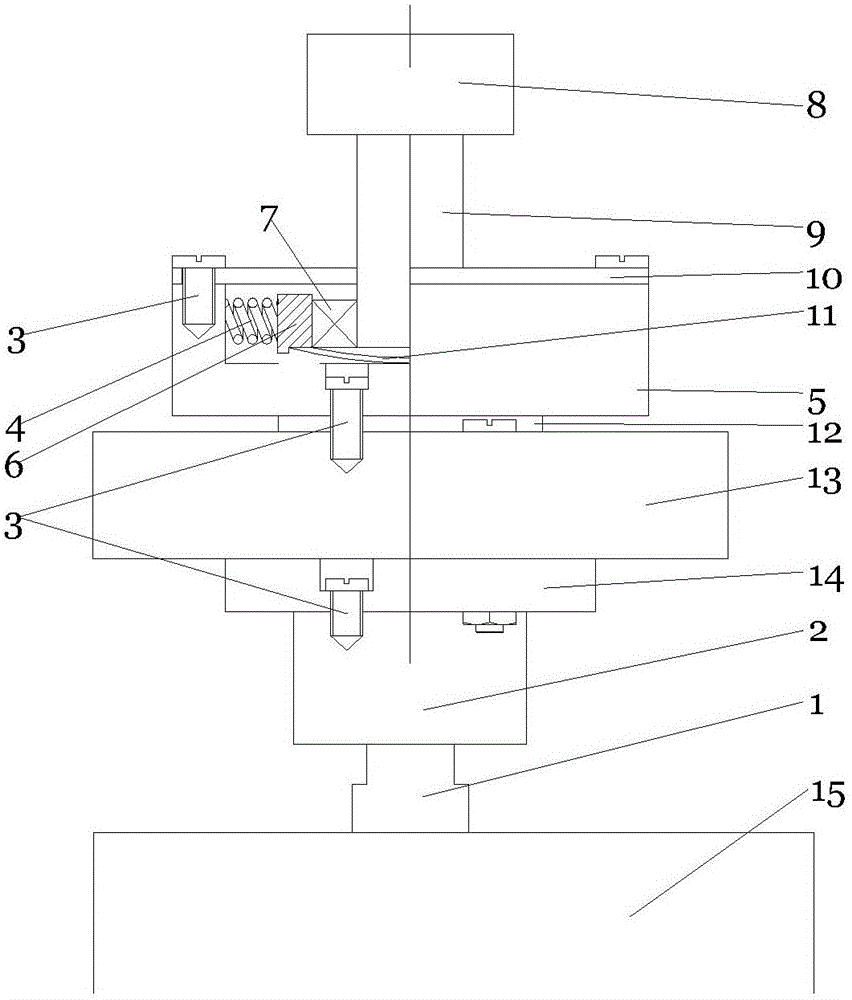

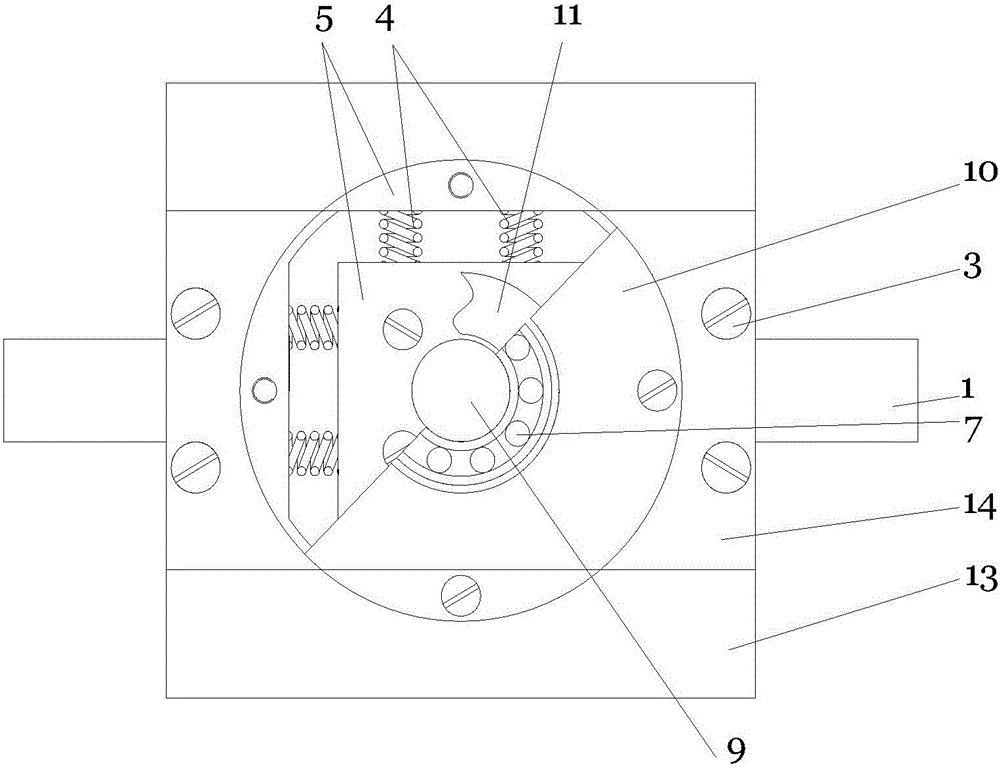

[0017] Such as Figure 1-4 As shown, a test device for detecting the degradation of the comprehensive performance of the rolling linear guide pair, the linear guide pair of the device is installed on the machine tool workbench 15, the linear guide rail pair includes a guide rail 1 and a slider 2, and the slider 2 is installed on the guide rail 1 The force sensor 13 can detect the magnitude of the force in three directions at the same time, and the connecting plate 14 is used to connect the force sensor 13 and the slider 2; the upper part of the force sensor 13 is provided with a gasket 12, and the gasket 12 is connected to the groove type through an adhesive The connecting plate 5, the force sensor 13, the connecting plate 14, and the grooved connecting plate 5 are all connected together and fixed by screws 3; four sets of springs 4 are housed in the grooved connecting plate 5, and the elastic coefficient of the springs 4 is greater than that of the spindle acceleration process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com