Axis alignment method for direct coupling of polarization maintaining optical fiber ring terminal and integrated optical chip

A polarization-maintaining fiber ring and integrated optics technology, which is used in surveying, mapping and navigation, measuring devices, instruments, etc., can solve the problems of low coupling efficiency, difficult handling of polarization-maintaining fibers and Y-waveguide chips, and low axis alignment accuracy, etc. Accuracy and speed, repeatability and universality, precise control of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

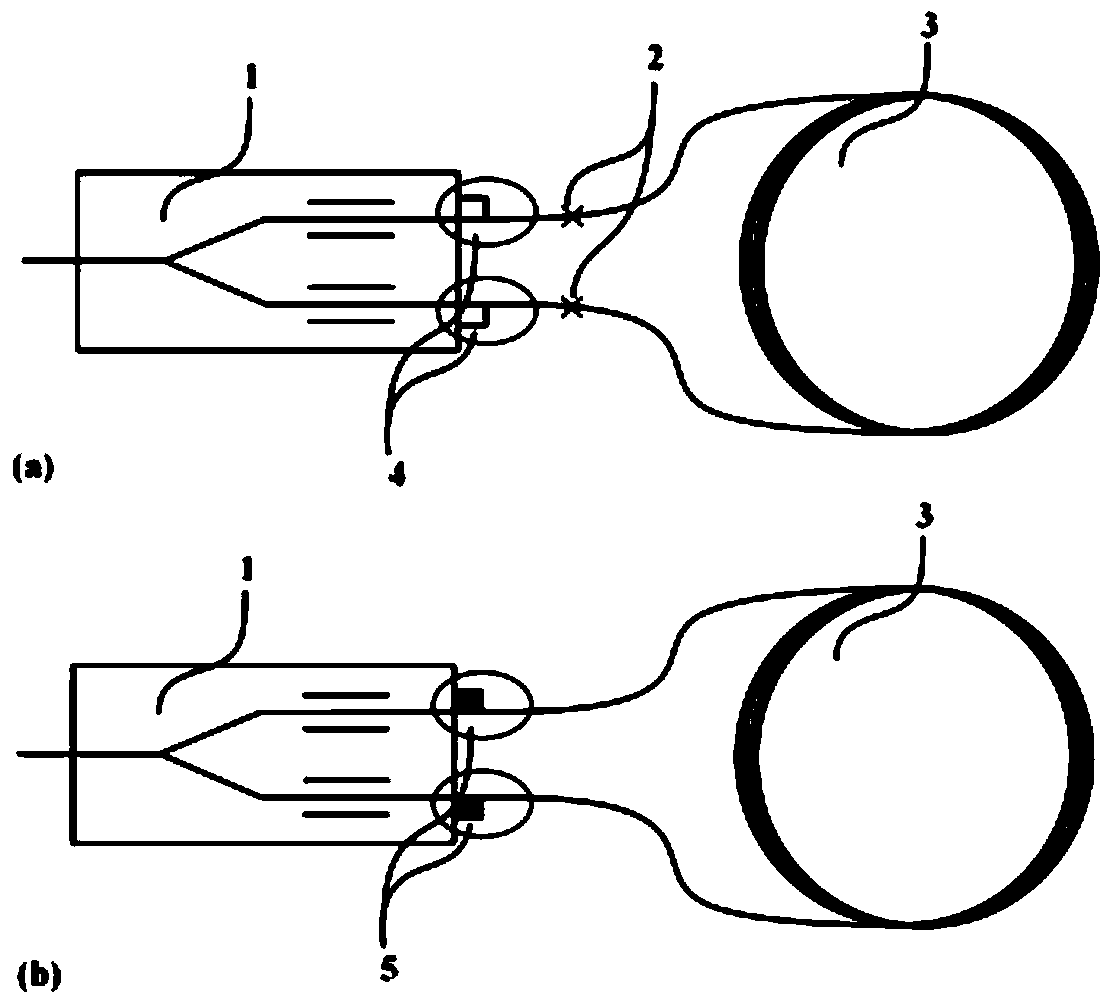

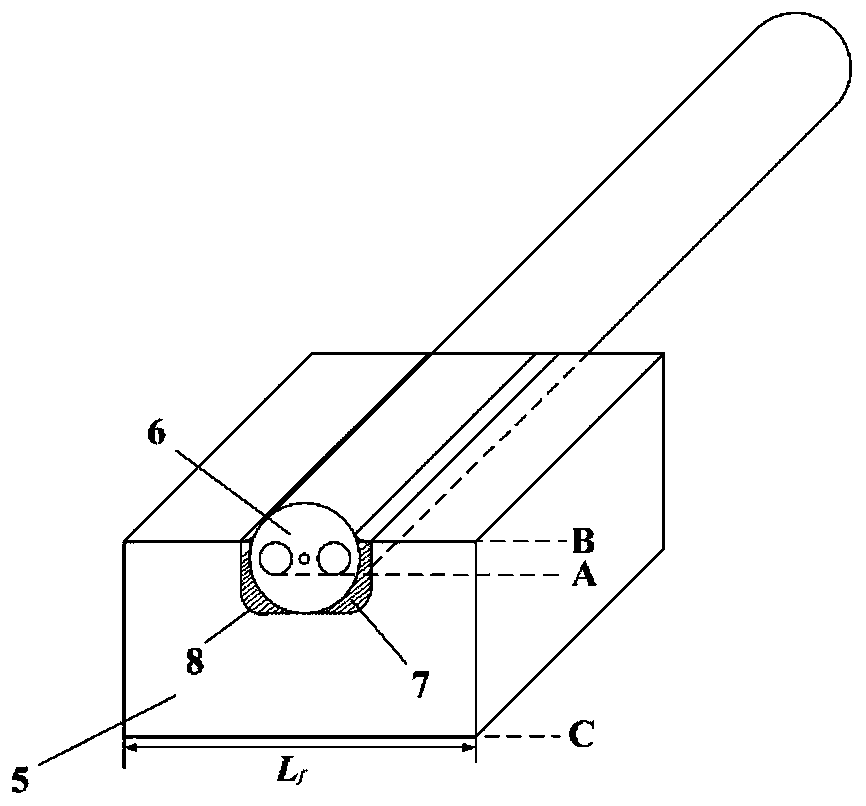

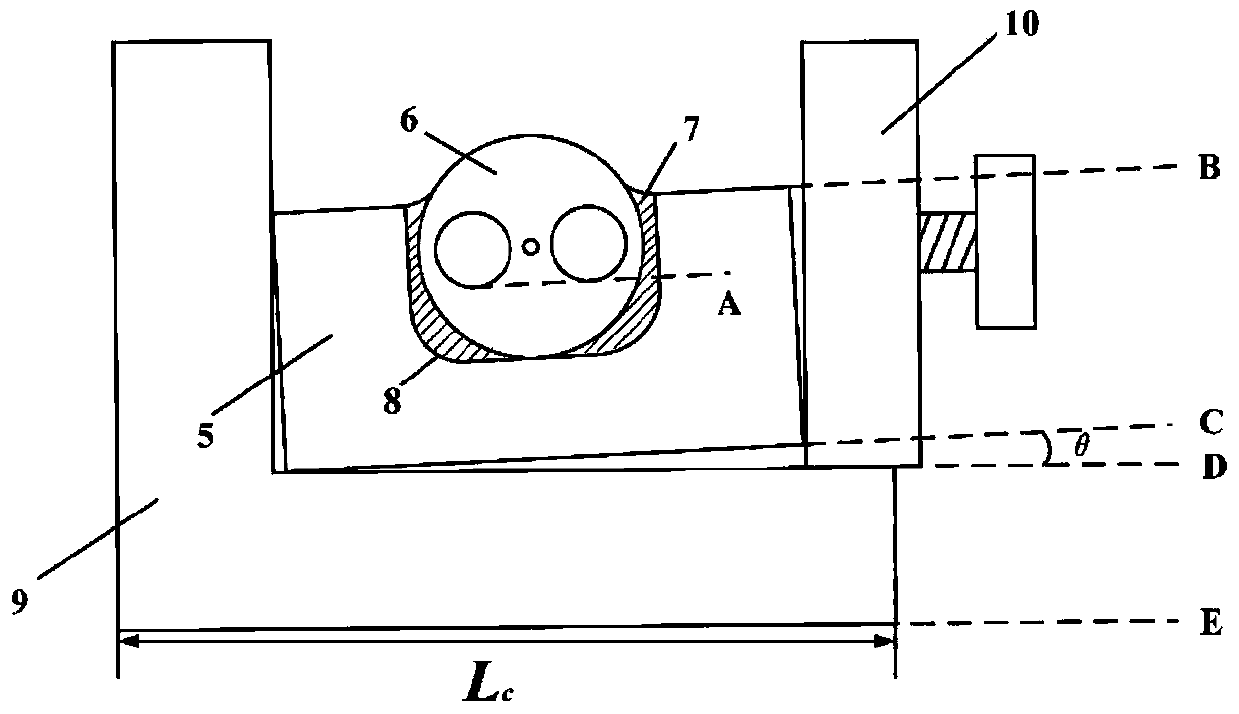

[0039] After the pigtail fiber of the polarization-maintaining optical fiber ring 3 is removed from the coating layer, it is bonded with the U-shaped optical fiber groove 8 through the curing glue 7 and then ground to produce the polarization-maintaining optical fiber ring terminal 5, the A line and the B line of the polarization-maintaining optical fiber ring terminal 5 The angle between the lines is less than 0.2°. Line A is the cat’s-eye baseline of the polarization-maintaining fiber, representing a polarization state of the beam in the polarization-maintaining fiber. Line B is the baseline on the upper surface of the polarization-maintaining fiber ring terminal 5, such as figure 2 shown. in length L f During the assembly process of the polarization-maintaining optical fiber ring terminal 5 and the coupling jig 9 with a diameter of 1-1.5mm, since the clamping device 10 did not compact the bottom surface of the polarization-maintaining optical fiber ring terminal 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com