Intra-drill pipe microwave communication distance calculation and optimum frequency point determination method

An optimal frequency point, microwave communication technology, applied in the direction of computing, drill pipe, drill pipe, etc., can solve the problems that are difficult to meet the requirements of gas drilling site construction, cannot be carried out, and cannot be predicted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical scheme of the present invention is described in further detail below in conjunction with accompanying drawing: the microwave communication distance calculation in the drill pipe and the optimal frequency point determination method, it comprises the following steps:

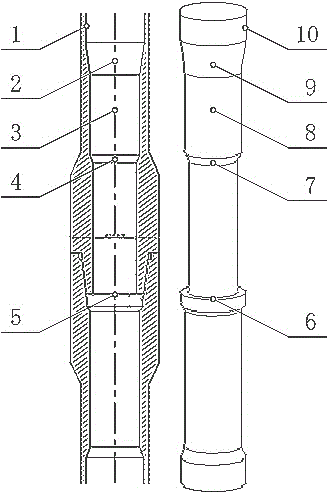

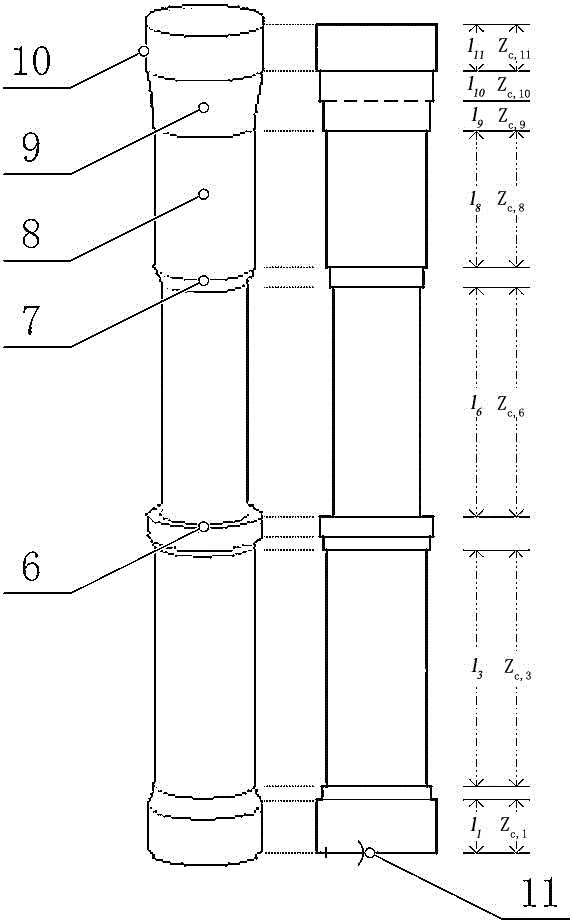

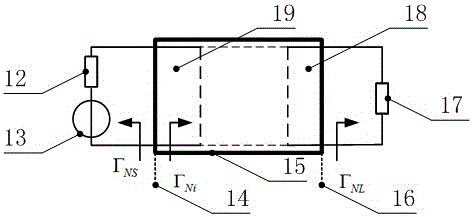

[0051] Such as figure 1 As shown, the present invention regards the inner wall of the drill pipe as an irregular cylindrical waveguide, and uses the microwave transmission line theory to analyze its microwave signal transmission status, and the frequency point of the microwave signal is f. According to the drill pipe structure drawings and measured dimensions, the drill pipe waveguide model 10 is established for the drill pipe inner wall structure 1 presented by the inner wall after the drill pipes are tightly connected, ignoring the thread and small gap factors. The inner diameter fixed pipe section 3 is regarded as the equal diameter waveguide section 8; the discontinuous inner diameter muta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap