A piezoelectric vibration energy harvester

An energy harvester, piezoelectric technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem that the vibration energy harvester cannot adjust the resonance frequency band , to achieve the effect of simple structure, improved recovery efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

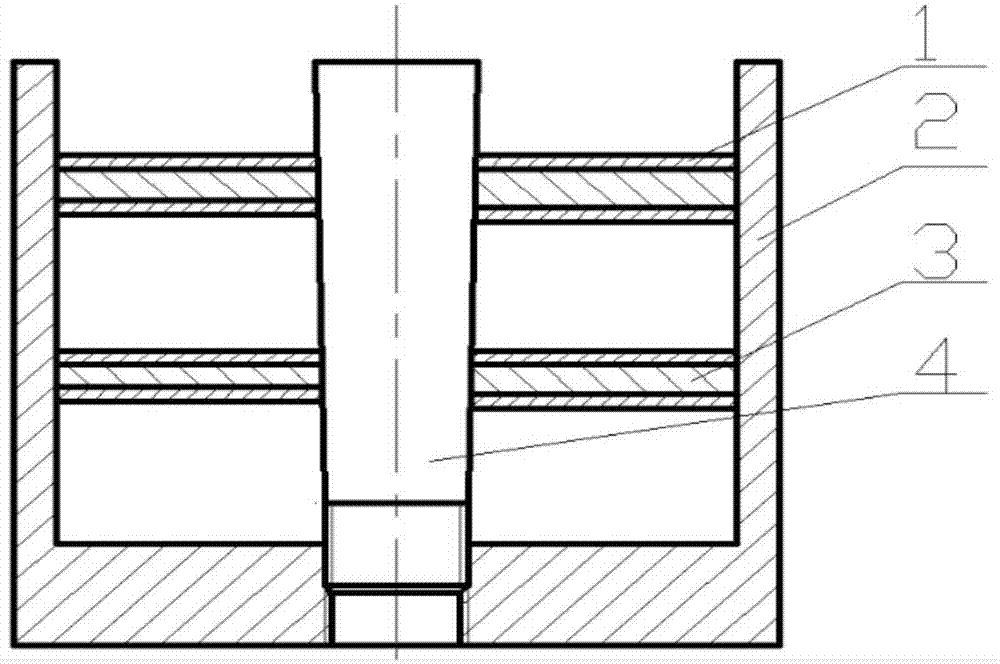

[0020] The present invention utilizes the d31 coupling working mode of the piezoelectric sheet, that is, the force direction is perpendicular to the polarization direction of the piezoelectric sheet, adopts the beam structure to recover the vibration energy of the engine, and converts the vibration energy into useful electric energy. Weights can be placed to lower the resonant frequency of the energy harvester.

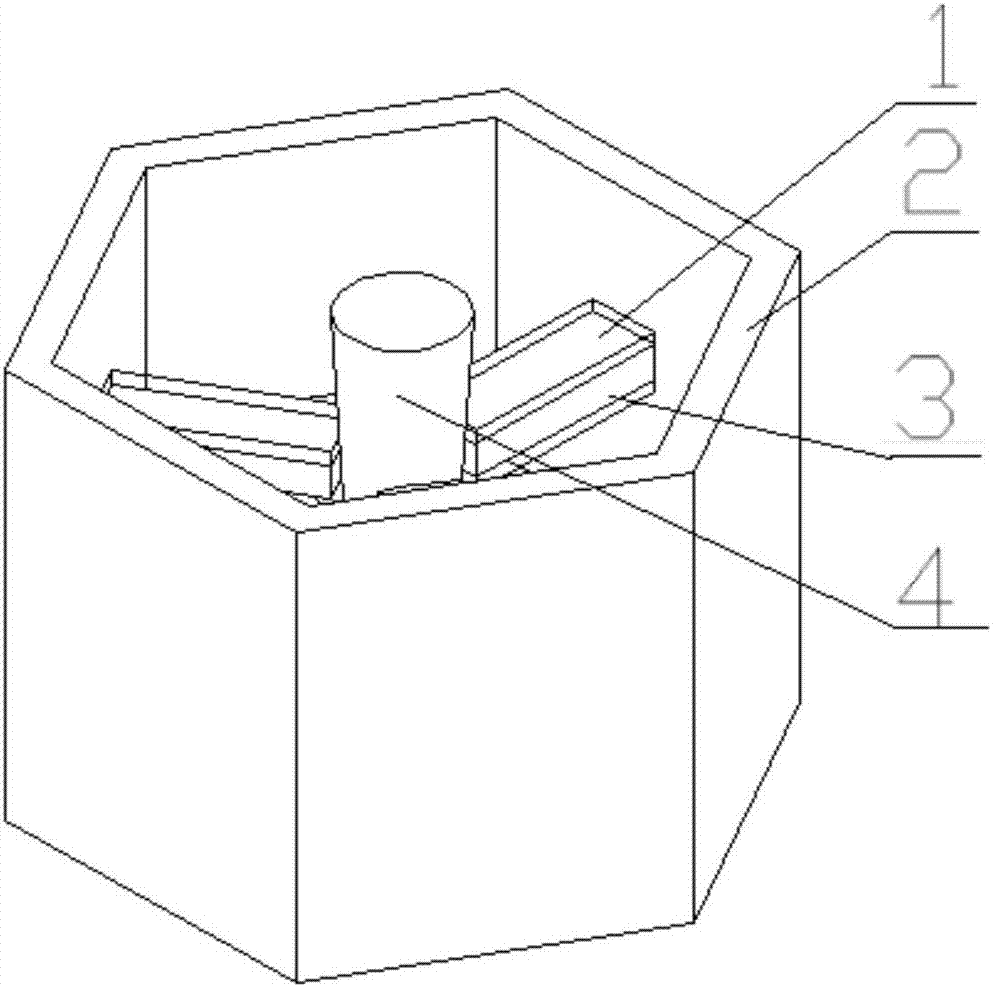

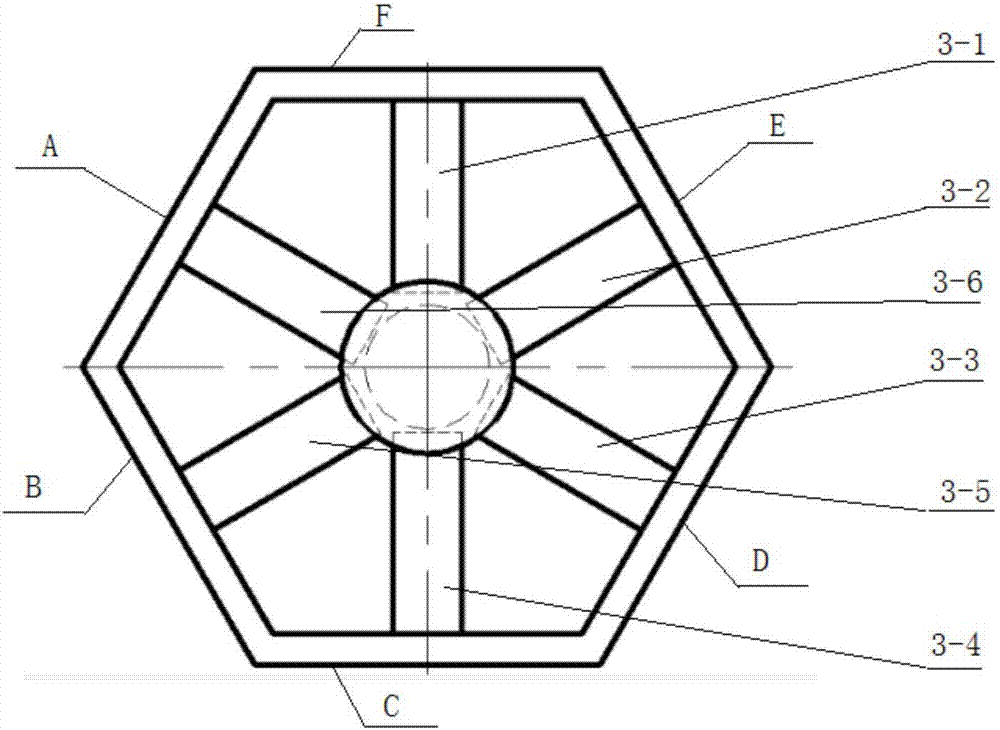

[0021] Such as Figure 1-3 As shown, a piezoelectric vibration energy harvester includes a piezoelectric sheet 1, a hollow hexagonal prism shell 2, a beam 3, and a circular frustum 4; the material of the hexagonal prism shell 2 is aluminum alloy; the hexagonal prism shell 2 There are upper and lower layers of beams 3 welded on the inner side, and three beams 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com