Nozzle plate for fuel injection device

A fuel injection device and a fuel injection technology are applied in the directions of the fuel injection device, the charging system, the engine components, etc., which can solve the problems such as the inability to determine the advancing direction of the spray 105, the inability to change the advancing direction of the spray 105, etc., so as to improve the fuel consumption efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

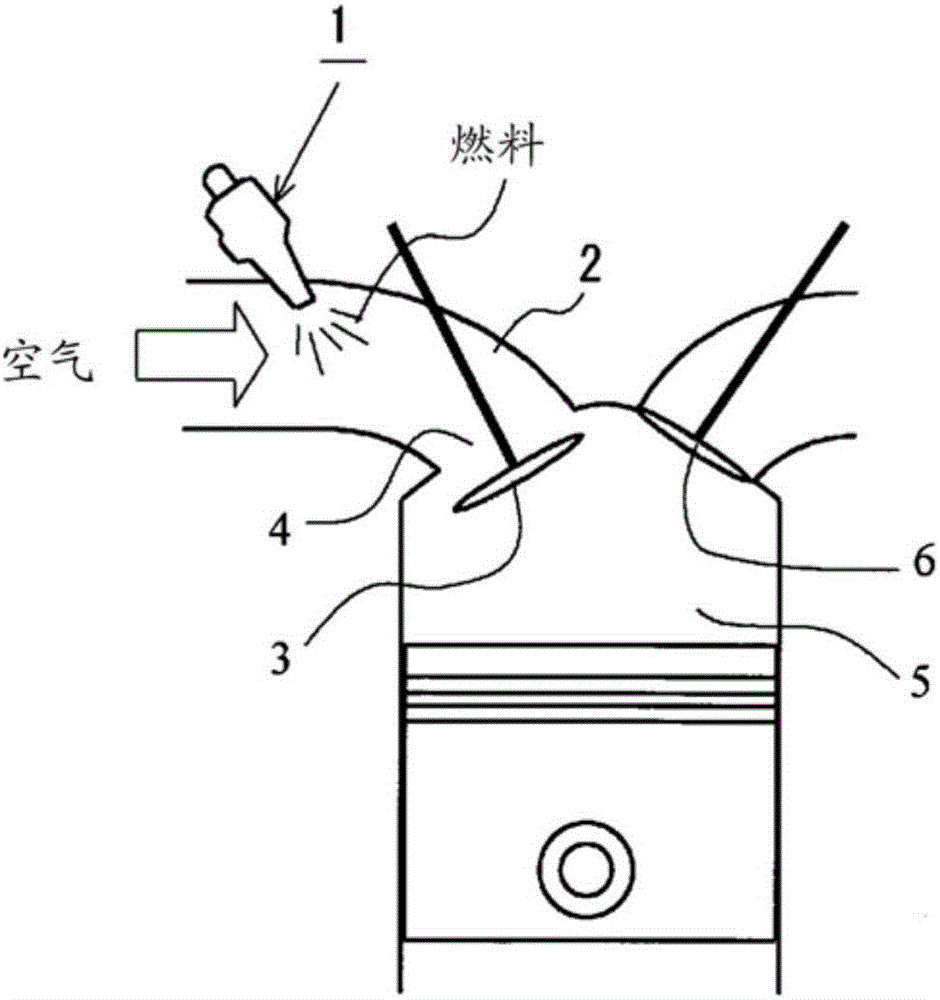

[0031] (Use status of fuel injection device)

[0032] figure 1 It is a figure which schematically shows the usage state of the fuel injection apparatus 1 to which the nozzle plate for fuel injection apparatuses of this embodiment is attached. as it should figure 1 As shown, the fuel injection device 1 of the port injection method is installed in the middle of the intake pipe 2 of the 4-valve engine. Fuel is injected into the air pipe 2 to mix the air introduced into the intake pipe 2 with the fuel, and the combustible mixture is supplied from the intake port 4 into the cylinder 5 . also, figure 1 Only one of the two intake valves 3 and one of the two exhaust valves (exhaust valves) 6 is shown.

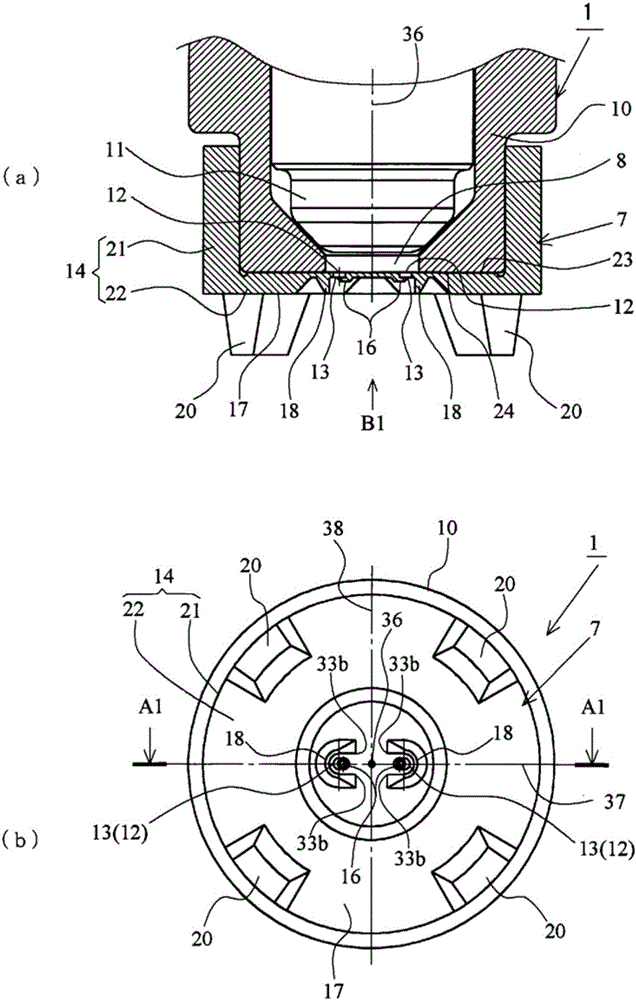

[0033] (Schematic structure of fuel injection device)

[0034] figure 2 It is a figure which shows the front-end side of the fuel injection apparatus 1 to which the nozzle plate 7 for fuel injection apparatuses (hereinafter referred to as a nozzle plate) is attached. also, f...

no. 2 approach

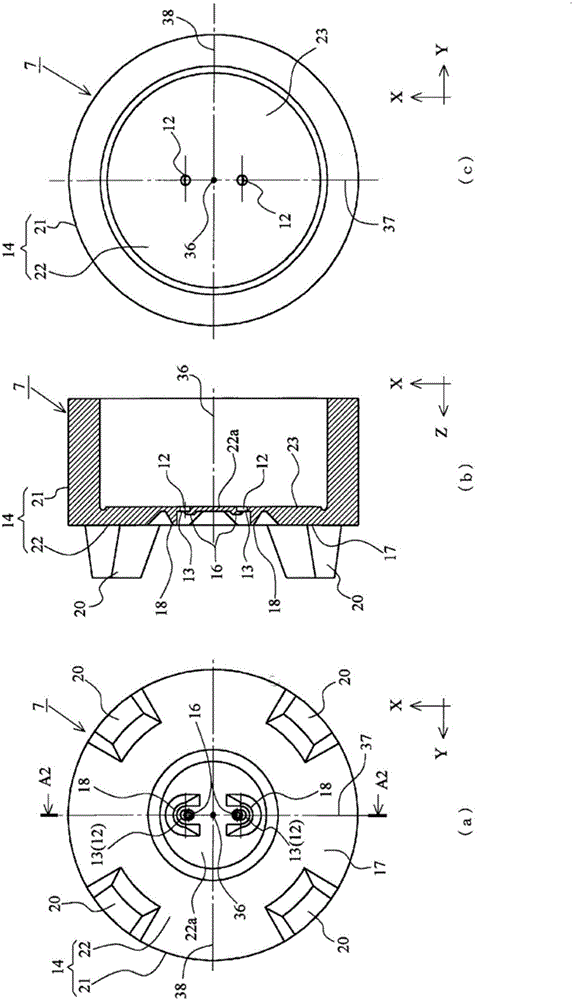

[0053] Image 6 It is a figure which shows a part of the nozzle plate 7 of 2nd Embodiment of this invention, and is a figure which shows the 1st modification of the nozzle plate 7 of 1st Embodiment. In addition, in the nozzle plate 7 of the present embodiment, the same reference numerals are attached to the same parts as those of the nozzle plate 7 of the first embodiment, and descriptions that overlap with those of the nozzle plate 7 of the first embodiment are omitted.

[0054] The nozzle plate 7 of the present embodiment is formed in such a manner that the inner wall surface 31 of the spray direction changing device 18 becomes an inclined surface, and the inner wall surface 31 faces the normal direction ( Image 6 (b) + Z axis direction) open.

[0055] The nozzle plate 7 of this embodiment can make the spray sprayed from the orifice 13 collide with the inner wall surface 31 of the spray direction changing device 18, and the advancing direction of the spray colliding with t...

no. 3 approach

[0057] Figure 7 It is a figure which shows a part of the nozzle plate 7 of 3rd Embodiment of this invention, and is a figure which shows the 2nd modification of the nozzle plate 7 of 1st Embodiment. In addition, in the nozzle plate 7 of the present embodiment, the same reference numerals are attached to the same parts as those of the nozzle plate 7 of the first embodiment, and descriptions that overlap with those of the nozzle plate 7 of the first embodiment are omitted.

[0058] In the nozzle plate 7 of the present embodiment, when the bottom wall portion 22 (thin wall portion 22a) is viewed from the front side (in a planar view), the first inner wall surface portion 32 of the spray direction changing device 18 is formed to interfere with the The semicircle concentric with the center 16 a of 16 is a semicircle eccentric with respect to the center 12 a of the nozzle hole 12 . Such as Figure 7 As shown in (a), the first inner wall surface 32 is closest to the outlet 15 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com