Driver's cab rear wallboard damping device

A shock absorbing device and cab technology, applied in transportation, packaging, vehicle parts, etc., can solve the problems of cab staff discomfort, increased cab noise, high vibration frequency, etc., to achieve simple structure, reduce vibration, and production low cost effect

Inactive Publication Date: 2016-10-19

扬州市和力机械钣金有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the cab is relatively close to the engine, so the vibration frequency is relatively high. During the operation of the driver, the resonance with the cab is relatively large, which causes great discomfort to the staff in the cab. Increased noise in the cab

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

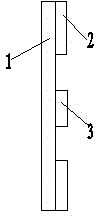

[0008] The cab rear wall plate damping device, the shock absorbing device includes a rear wall plate 1, a shock absorbing block 2 and a sound-absorbing block 3, the shock absorbing block 3 is arranged on the surface of the rear wall plate 1, and the shock absorbing There are four blocks 2 arranged at the four corners of the surface of the rear wall 1 , and the sound-absorbing block 3 is arranged at the center of the surface of the rear wall 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a driver's cab rear wallboard damping device. The damping device comprises a rear wallboard, damping blocks and a sound-absorbing block; the damping blocks are installed on the surface of the rear wallboard; there are four damping blocks which are installed at the four angles of the rear wallboard surface; the sound-absorbing block is installed at the center of the rear wallboard surface. The device has simple structure, is convenient for installation, and has low production cost; the device can reduce resonance vibration and vibratory sensation and reduce noises; by means of the self-weight of the damping blocks, the vibration frequency of part of the driver 's cab is changed, which forms a stable and comfortable work environment for workers.

Description

technical field [0001] The invention relates to a rear panel of a cab, in particular to a damping device for the rear panel of a cab. Background technique [0002] At present, the cab is relatively close to the engine, so the vibration frequency is relatively high. During the operation of the driver, the resonance with the cab is relatively large, which causes great discomfort to the staff in the cab. Increased noise in the cab. Contents of the invention [0003] In order to solve the above problems, the present invention provides a cab rear wall panel shock absorber with simple structure, convenient installation, low production cost, reduced resonance, reduced vibration feeling and reduced noise. [0004] The technical solution of the present invention is: the shock absorbing device includes a rear wall plate, a shock absorbing block and a sound-absorbing block, the shock absorbing block is arranged on the surface of the rear wall plate, and four of the shock absorbing b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60R13/08

Inventor 柏斗国

Owner 扬州市和力机械钣金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com