High-efficiency grease gun filling device

A filler and grease gun technology, applied in the input of lubricating oil, engine components, engine lubrication, etc., can solve problems such as low filling efficiency, reduced equipment and oil well time rate, equipment damage, etc., and achieve good economic benefits And social benefits, slow down the cumbersome operation, improve the effect of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

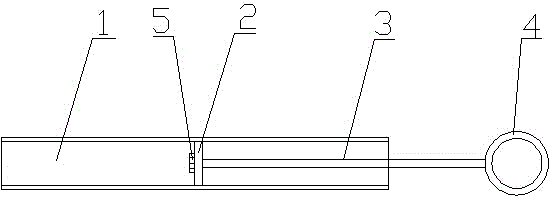

[0009] Such as figure 1 As shown, the grease gun high-efficiency filler includes a filling cylinder 1, a piston 2, and a push rod 3. The piston 2 is fixedly connected to one end of the push rod 3, and the other end of the push rod 3 is provided with a bracelet 4, and the piston 2 slides Fitted in the filling cylinder 1 , the circumferential surface of the piston 2 is in close contact with the inner wall of the filling cylinder 1 . The end of push rod 3 is provided with screw thread, and the middle part of piston 2 is provided with through hole, and piston 2 penetrates one end of push rod 3 through through hole, and the end of push rod 3 is threadedly connected with a nut 5, is used for fixing piston 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com