A kind of drilling method of polymer thermistor printed circuit board

A technology for printed circuit boards and thermistors, applied in printed circuits, printed circuit manufacturing, boring/drilling, etc., can solve problems such as residual glue in holes, unstable expansion and shrinkage, and large ridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

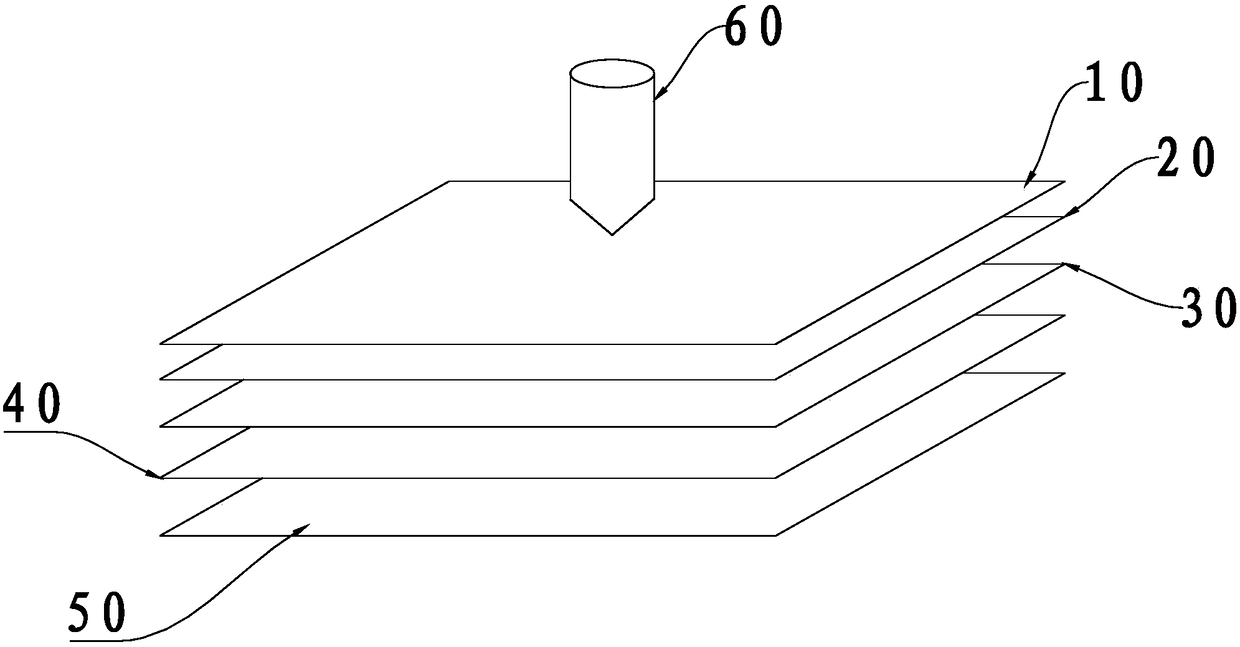

[0020] see figure 1 as shown, figure 1 It is a schematic diagram of drilling a printed circuit board for a polymer thermistor of the present invention. The present invention provides a kind of drilling method aimed at the polymer thermistor printed circuit board, and it adopts the mode of drilling and stacking boards, and places phenolic resin board 40, PCB board 30, cooling board 40 from bottom to top on machine platform 50 successively. Punching plate 20 and aluminum sheet 10;

[0021] Then adjust the parameters of drill bit 60, control the rotating speed of drill bit 60 to 100KRMP, the feed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com