A glue-feeding device and glue-feeding method for injection-molded water tanks

A technology for glue feeding and water tank, which is applied in the field of glue feeding devices for injection molding water tanks. It can solve the problems of flow lines and shrinkage of water tanks, and achieve the effects of solving shrinkage, improving pressure retention, and solving weld line problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

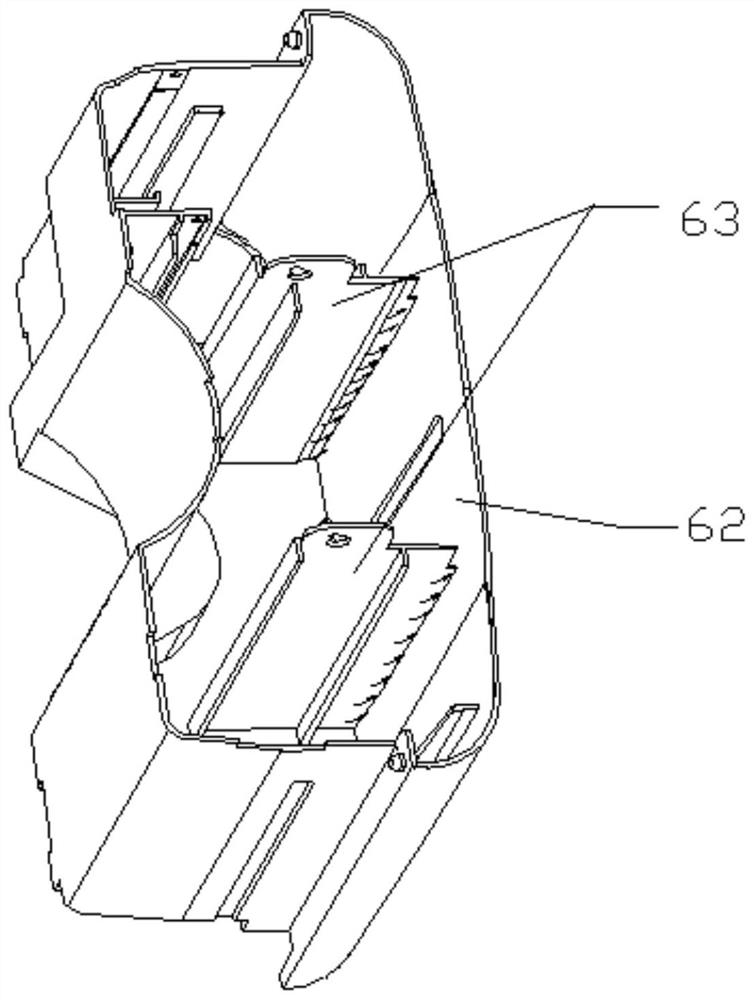

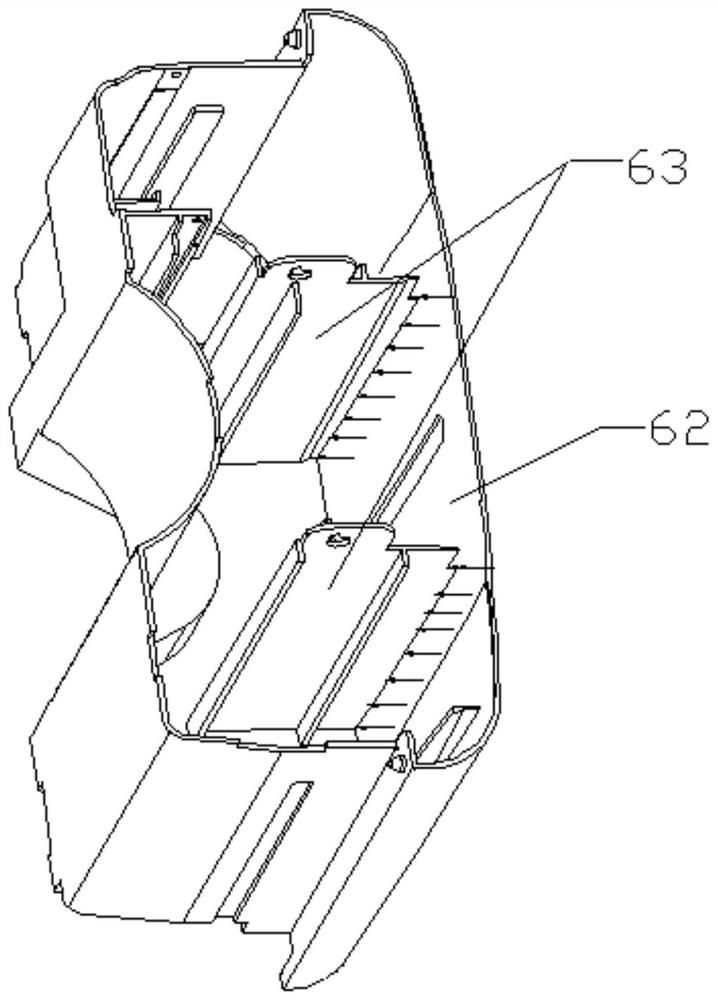

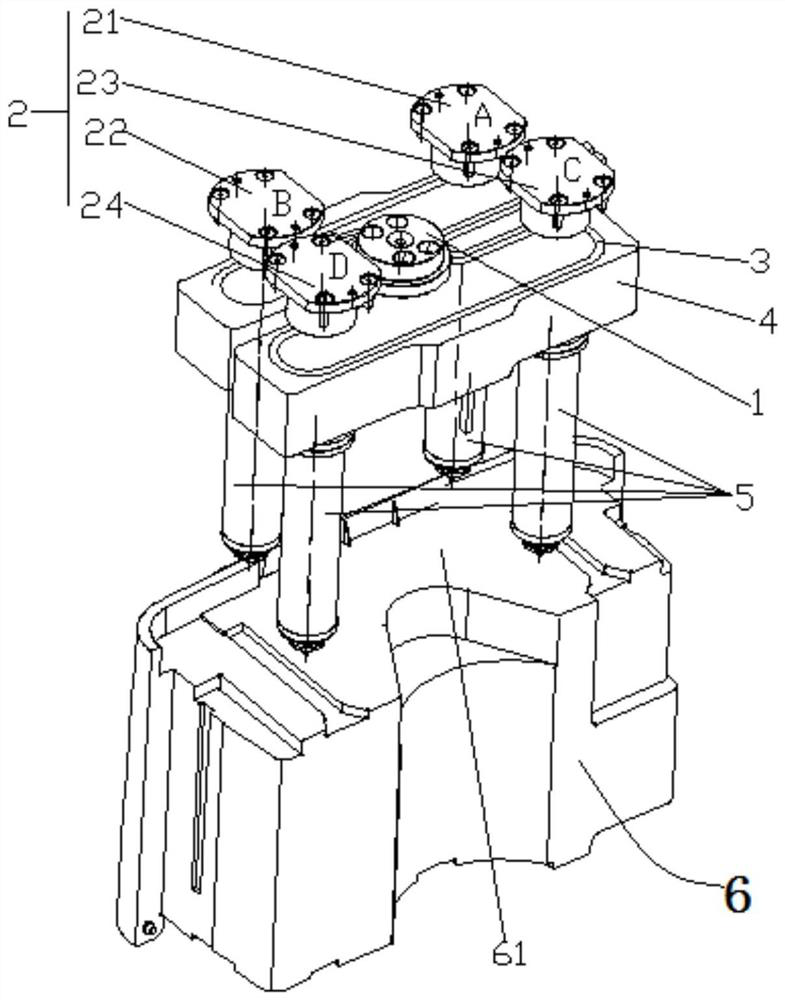

[0038]Such asFigure 2-3As shown, a glue feeding device for injection molding water tank 6 of the present invention includes

[0039]There are at least four needle valve nozzles arranged in two rows, including a first row of needle valve nozzles located close to the appearance surface 62 of the water tank 6, and a second row of needle valve nozzles located away from the appearance surface 62 of the water tank 6, The needle valve nozzles are all point at the bottom 61 of the water tank 6 to feed glue;

[0040]Glue injection structure to inject glue into each of the needle valve nozzles.

[0041]Since the first row of needle valve nozzles are located close to the appearance surface 62 of the water tank 6, the rubber is first filled in the cavity where the appearance surface 62 of the water tank 6 is located, and then the cavity where the rib 63 is located, which can effectively avoid the appearance of the product Flow lines are generated on the surface 62, and at the same time, the arrangement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com