A thermal sleeve positioning device for motor test gears

A technology for positioning device and motor test, which is applied in the direction of machine gear/transmission mechanism testing, measuring device, workpiece clamping device, etc., which can solve the problems of motor shaft and test gear damage, scrapping of motor shaft and test gear, and failure to complete the test. , to achieve the effect of preventing slipping and falling off, simple and fast operation, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

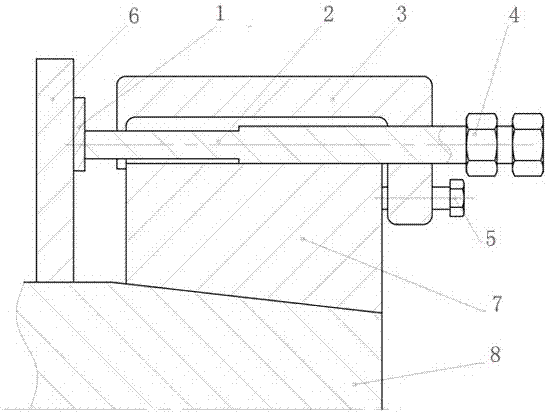

[0017] Such as figure 1 As shown, a motor test gear shrink-fit positioning device includes a sample block 1, a positioning screw 2, a positioning frame 3, a lock nut 4 and a fixing bolt 5, the positioning frame 3 is an inverted U shape, and the positioning screw 2 is from One end of the positioning frame 3 is passed to the other end, the sample block 1 is arranged at the front end of the positioning screw 2, the lock nut 4 is arranged at the rear end of the positioning frame 3, and the fixing bolt 5 is screwed into the inside from the outside at the rear end of the positioning frame 3 .

[0018] The rear end of the positioning frame 3 is higher than the front end, and the fixing bolt 5 is arranged at the rear end of the positioning frame 3 .

[0019] There are two locking nuts 4, both of which are arranged at the rear end of the spacer 3.

[0020] Working principle of the present invention:

[0021] 1. After cleaning the outer cone surface of the motor shaft 8 and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com