Robot deburring system and method through visual inspection

A robotic system and visual inspection technology, applied in the field of deburring systems, can solve the problems of human harm, low efficiency and poor accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

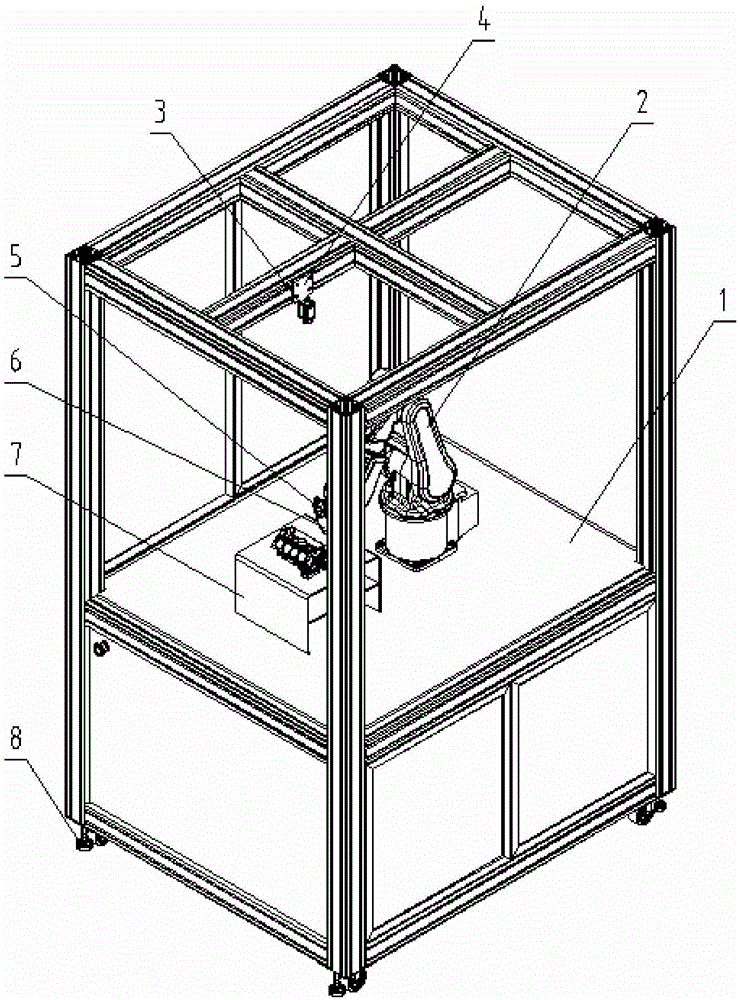

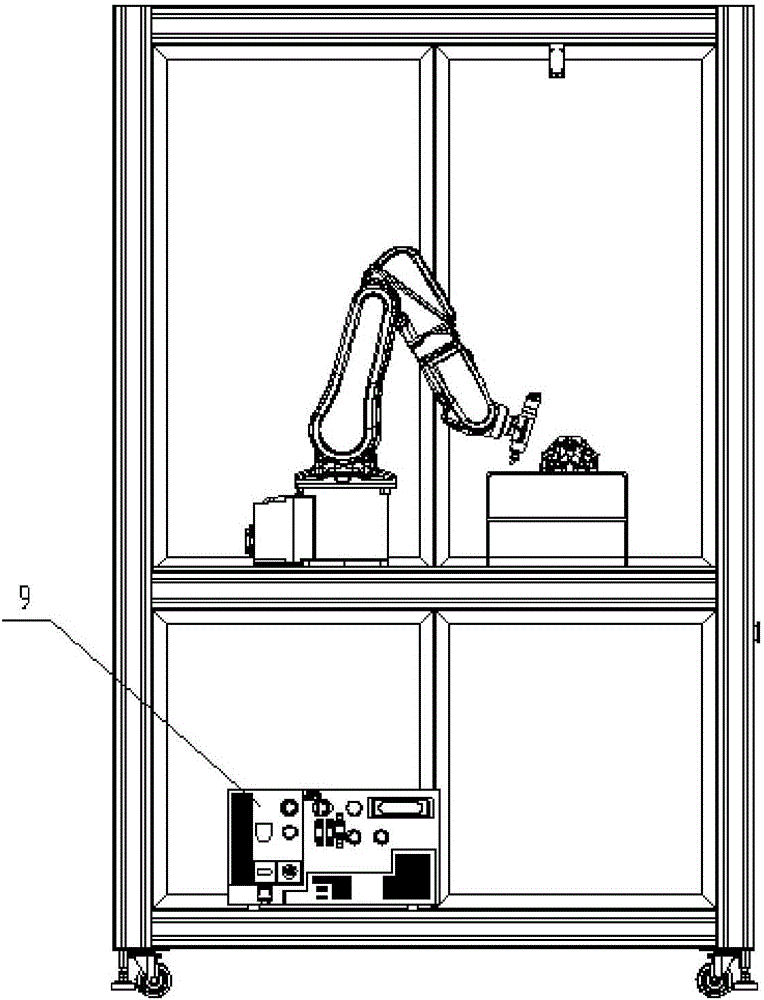

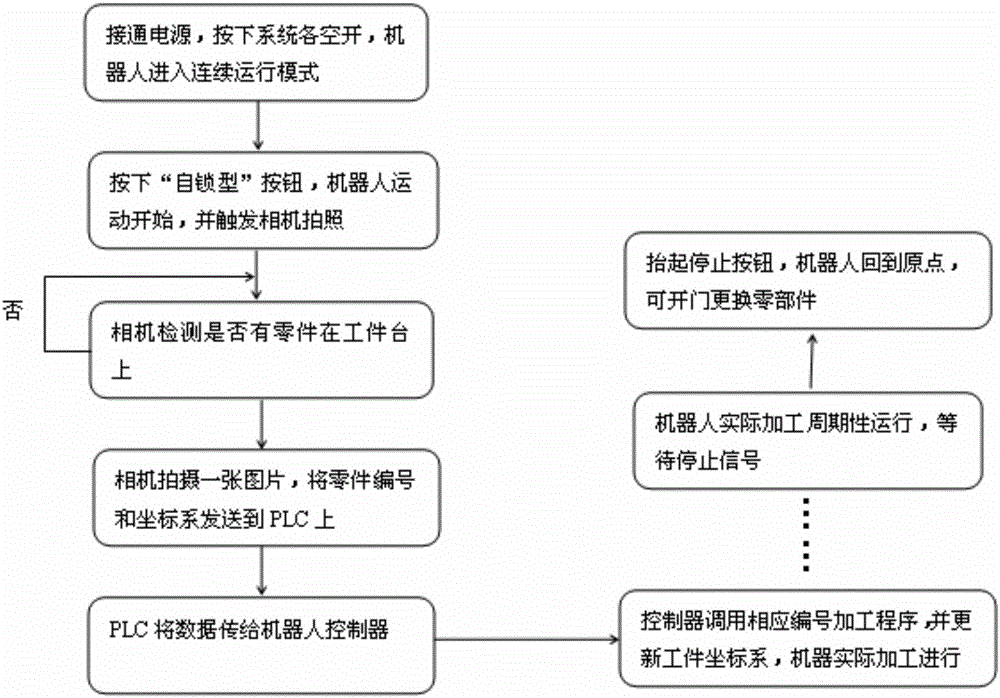

[0022] Such as Figure 1-2 As shown, the robot deburring system using visual inspection according to the present invention includes a robot installation frame 1, a robot system, a high-speed electric spindle system, a visual camera system, a PLC control module, and a workpiece placement platform 7 .

[0023] Further, the robot installation frame 1 is used as an installation platform for the installation and positioning of the robot 2 and the robot control box and other components, and plays a role in protecting the robot 2 and other components. The bottom of the installation frame 1 is equipped with four sets of composite casters 8, including adjustable feet and pulleys, so that the equipment can be moved freely, and the height of the installation frame 1 can be slightly adjusted.

[0024] The robot system is composed of a robot 2, a robot control box, and a teaching pendant. The robot 2 completes corresponding processing actions according to a pre-programmed program.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com