Brake pump and its application on loader

A brake pump and brake caliper technology, applied in the arrangement of pumps/compressors, mechanical equipment, vehicle parts, etc., can solve the problems of short moving distance of the brake pedal, inconvenient use, inconvenient maintenance and disassembly, etc., to save driving intensity, improve The effect of driving safety and convenient maintenance and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

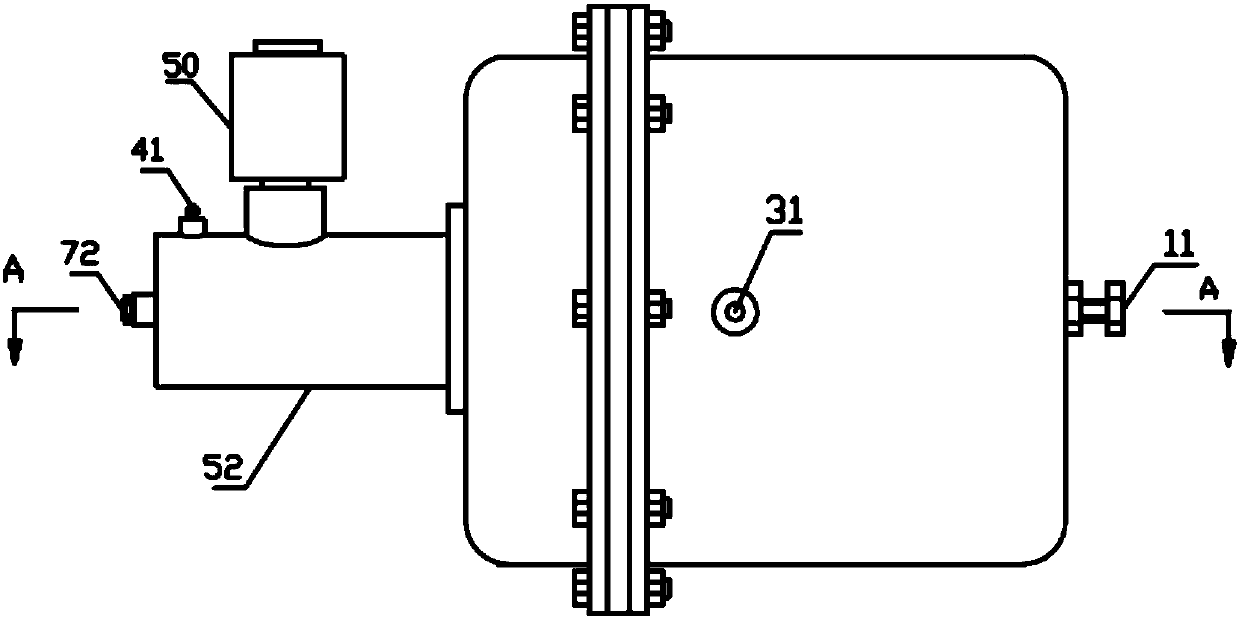

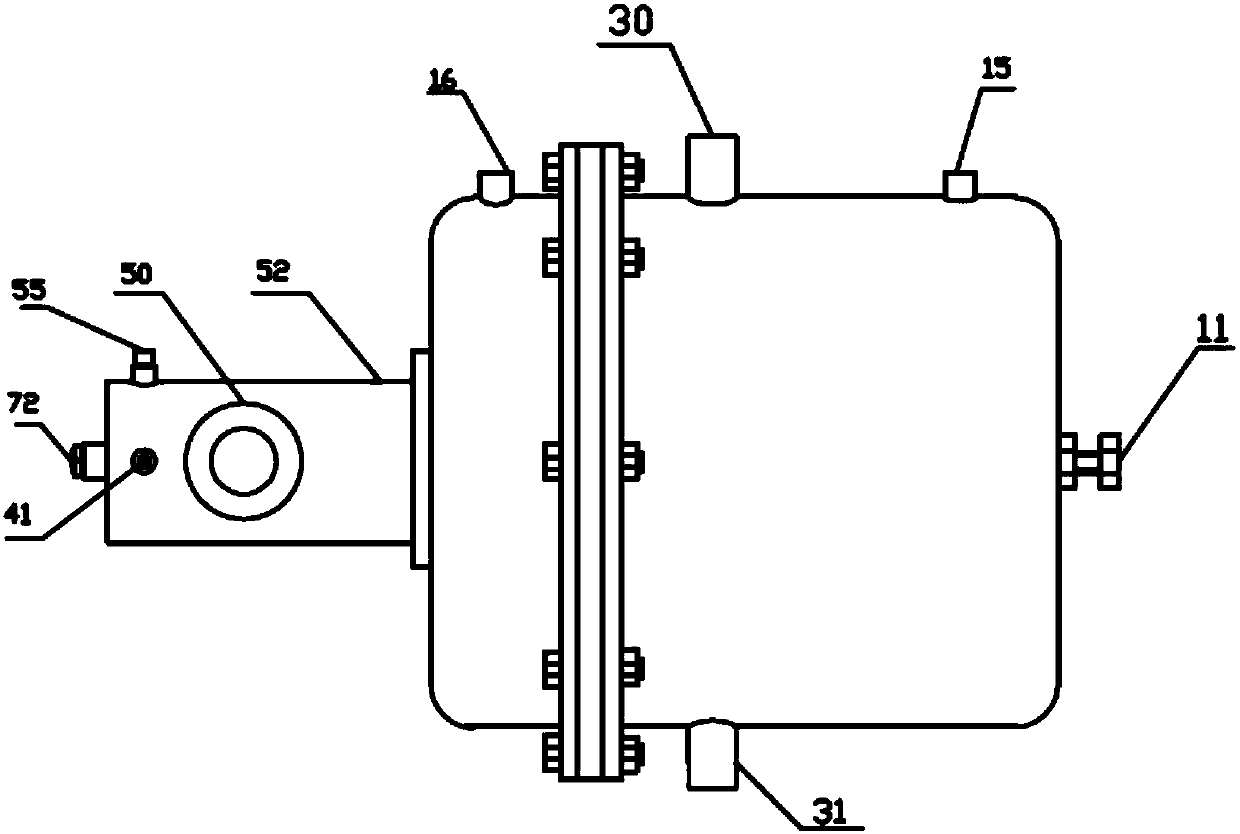

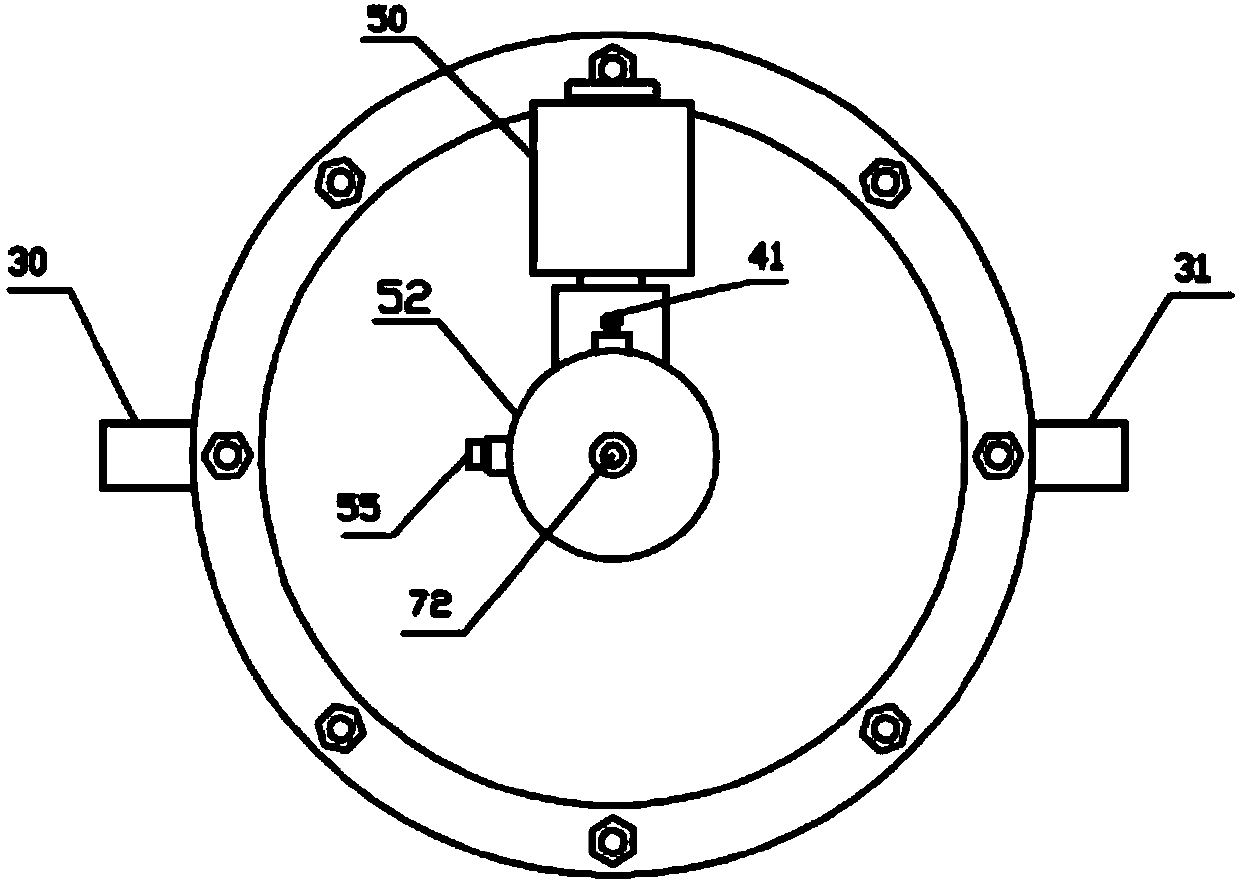

[0052] The following will be described in detail in conjunction with the accompanying drawings and embodiments.

[0053] Such as Figure 1 to Figure 7 As shown, the brake pump of the present invention includes a brake pump housing, and a brake chamber, a service brake chamber and a parking brake chamber are arranged in the brake pump housing. In this embodiment, the brake chamber housing 52 is provided with a brake moving cavity. The service brake chamber is located on the left side of the parking brake chamber, and the brake chamber is located on the left side of the service brake chamber; the service brake chamber is provided with a first rubber cup 5, and the first rubber cup 5 applies the service brake The cavity is divided into a service brake left chamber 33 and a service brake air storage chamber 2, the service brake air storage chamber 2 is located on the right side of the service brake left chamber 33, and the service brake air storage chamber 2 is provided with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com