Automobile part storage rack

A technology for auto parts and racks, which is applied to trolley accessories, trolleys, motor vehicles, etc., can solve the problems of inconvenience to find the required parts, time-wasting, time- and energy-wasting to find and take, and achieve convenient and labor-saving movement. Simple structure and easy access to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

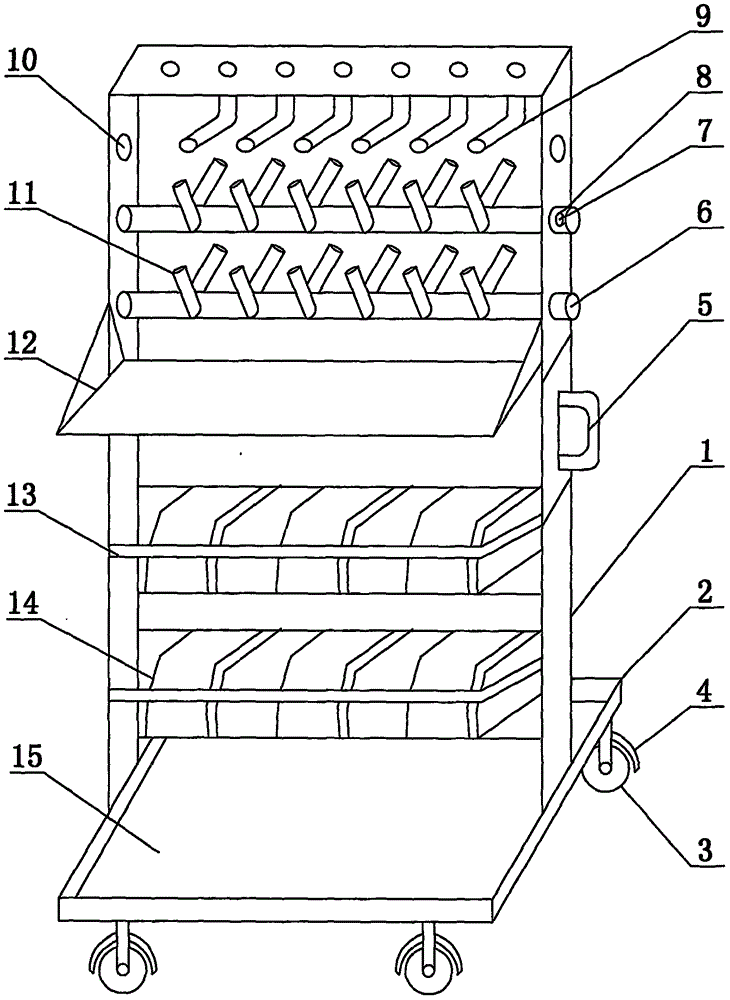

[0016] Such as figure 1 Shown, a kind of auto parts shelf, it comprises base 2, is characterized in that: the bottom of described base 2 is equipped with traveling wheel 3, and described traveling wheel 3 is equipped with wheel fixing device 4, and described base 2 A storage tank 15 is provided, the upper part of the base 2 is connected with a support frame 1, the support frame 1 is equipped with a handle 5, the support frame 1 is provided with a fixing hole 10, and the fixing hole 10 is installed There is a hanging rod supporting frame 6, and the described hanging rod supporting frame 6 is equipped with a hanging rod 11, and the two ends of the described hanging rod supporting frame 6 are provided with limiting holes 7, and the described limiting holes 7 are equipped with limiting pins 8. The support frame 1 is connected with a hook 9, the support frame 1 is connected with a display frame 12, the support frame 1 is connected with a fixed frame 13, and the fixed frame 13 is eq...

Embodiment 2

[0019] Such as figure 1 Shown, a kind of auto parts shelf, it comprises base 2, is characterized in that: the bottom of described base 2 is equipped with traveling wheel 3, and described traveling wheel 3 is equipped with wheel fixing device 4, and described base 2 A storage tank 15 is provided, the upper part of the base 2 is connected with a support frame 1, the support frame 1 is equipped with a handle 5, the support frame 1 is provided with a fixing hole 10, and the fixing hole 10 is installed There is a hanging rod supporting frame 6, and the described hanging rod supporting frame 6 is equipped with a hanging rod 11, and the two ends of the described hanging rod supporting frame 6 are provided with limiting holes 7, and the described limiting holes 7 are equipped with limiting pins 8. The support frame 1 is connected with a hook 9, the support frame 1 is connected with a display frame 12, the support frame 1 is connected with a fixed frame 13, and the fixed frame 13 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com